SPR heavy metal ion sensing head of long-period fiber grating and production method thereof

A technology of heavy metal ions and optical fiber gratings, which is applied in the direction of material analysis, measuring devices, instruments, etc. through optical means, can solve the problems of cumbersome detection and troublesome heavy metal ion detection, and achieve the effect of fast detection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

[0028] Example 1

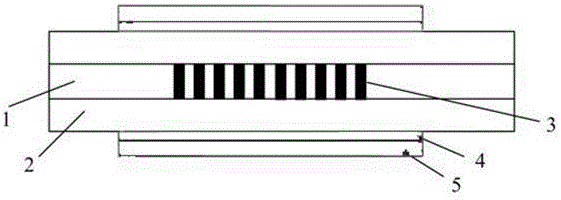

[0029] Such as figure 1 As shown, a long-period fiber grating SPR heavy metal ion sensor head includes a long-period fiber grating (LPG), a metal film 4, and a modified chitosan film 5. The long-period fiber grating includes a fiber containing a grating 3. The core 1 and the cladding 2 attached to the core 1, the period of the grating 3 is 100-500μm, the surface of the cladding 2 in the area of the grating 3 is plated with a 30-200nm thick metal film 4, the surface of the metal film 4 A modified chitosan film 5 with a thickness of 30 to 500 nm is prepared, and the modified chitosan film 5 can adsorb heavy metal ions.

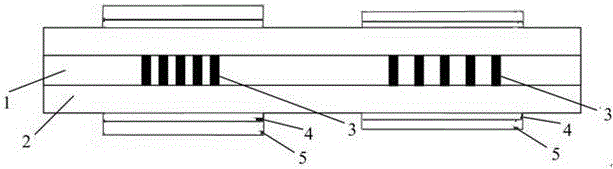

[0030] In the specific implementation process, such as figure 2 As shown, the long-period fiber grating includes multiple groups of gratings 3 with different periods. The regions of the gratings 3 with different periods have different modified chitosan films 5, and different modified chitosan films 5 can adsorb different heavy metal ions. , So...

Example Embodiment

[0034] Example 2

[0035] A method for manufacturing a long-period fiber grating SPR heavy metal ion sensor head for manufacturing the long-period fiber grating SPR heavy metal ion sensor head of Example 1, including the following steps:

[0036] S1: Put the long-period fiber grating in absolute ethanol and clean it with ultrasonic for 3-8 minutes twice, then wipe the cladding surface of the long-period fiber grating clean with absorbent cotton dipped in absolute ethanol and dry;

[0037] S2: The long-period fiber grating, which has been wiped clean and dried, is plated with a metal film on the cladding surface of the grating area, with a thickness of 30~200nm;

[0038] S3: According to the performance requirements of the fiber grating SPR heavy metal ion sensor head, prepare a chitosan solution with a mass concentration of 1-5% with acetic acid with a mass concentration of 0.5-5% until the chitosan solution becomes clear and viscous. Immediately modify the chitosan. Different modifie...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap