Method for assessing content of impure phases in LaFeSi-base magnetic refrigeration material

A technology of magnetic refrigeration materials and miscellaneous phases, applied in the fields of material magnetic variables, material analysis using radiation diffraction, etc., can solve the problems of long cycle, cumbersome detection, high cost, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be further described below in conjunction with specific embodiment:

[0018] A method for evaluating the impurity content in a LaFeSi-based magnetic refrigeration material, comprising the following steps:

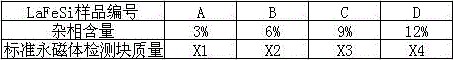

[0019] a. Take a number of LaFeSi-based magnetic refrigeration material samples with impurity content of 3%-12%, conduct XRD detection on the samples, estimate the impurity content in each sample according to the test results, and screen out the impurity in the measured samples The sample A with a phase content of 3%, the sample B with a heterogeneous content of 6%, the sample C with a heterogeneous content of 9%, and the sample with a heterogeneous content of 12%, the screened A, B, C, and D samples were then After SEM detection, the impurity content is evaluated according to the detection results. If the deviation between the SEM detection and evaluation results and the XRD detection and evaluation results exceeds 2%, then repeat step a u...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com