A Design Method of Crane Ring Beam

A design method and crane technology, applied in design optimization/simulation, calculation, constraint-based CAD, etc., can solve problems such as long optimization cycle, and achieve the effect of avoiding passive optimization and shortening the optimization design cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

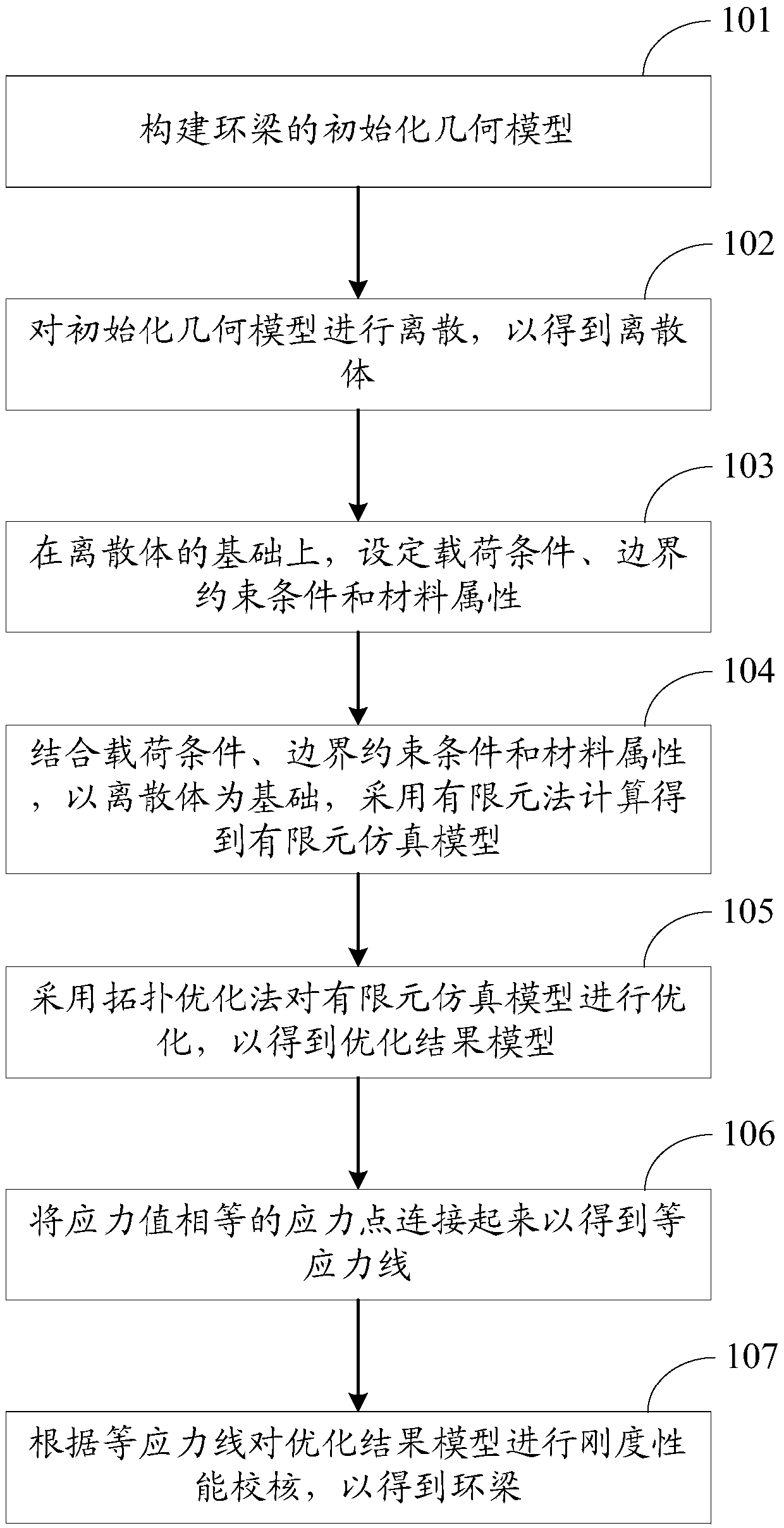

[0036] A design method of a crane ring beam provided by an embodiment of the present invention, such as figure 1 As shown, the design method includes:

[0037] Step 101: Construct an initial geometric model of the ring beam.

[0038] Step 102: Discretize the initial geometric model to obtain a discrete body.

[0039] Step 103: On the basis of the discrete body, set load conditions, boundary constraint conditions and material properties.

[0040] Step 104: Combining the load conditions, boundary constraint conditions and material properties, based on the discrete body, the finite element simulation model is obtained by using the finite element method.

[0041] Step 105: Optimizing the finite element simulation model by topology optimization method to obtain an optimization result model.

[0042] Step 106: Set the stress value interval on the optimization result model, and set the number of isostress lines N, select N stress values with equal difference in the stress value ...

Embodiment 2

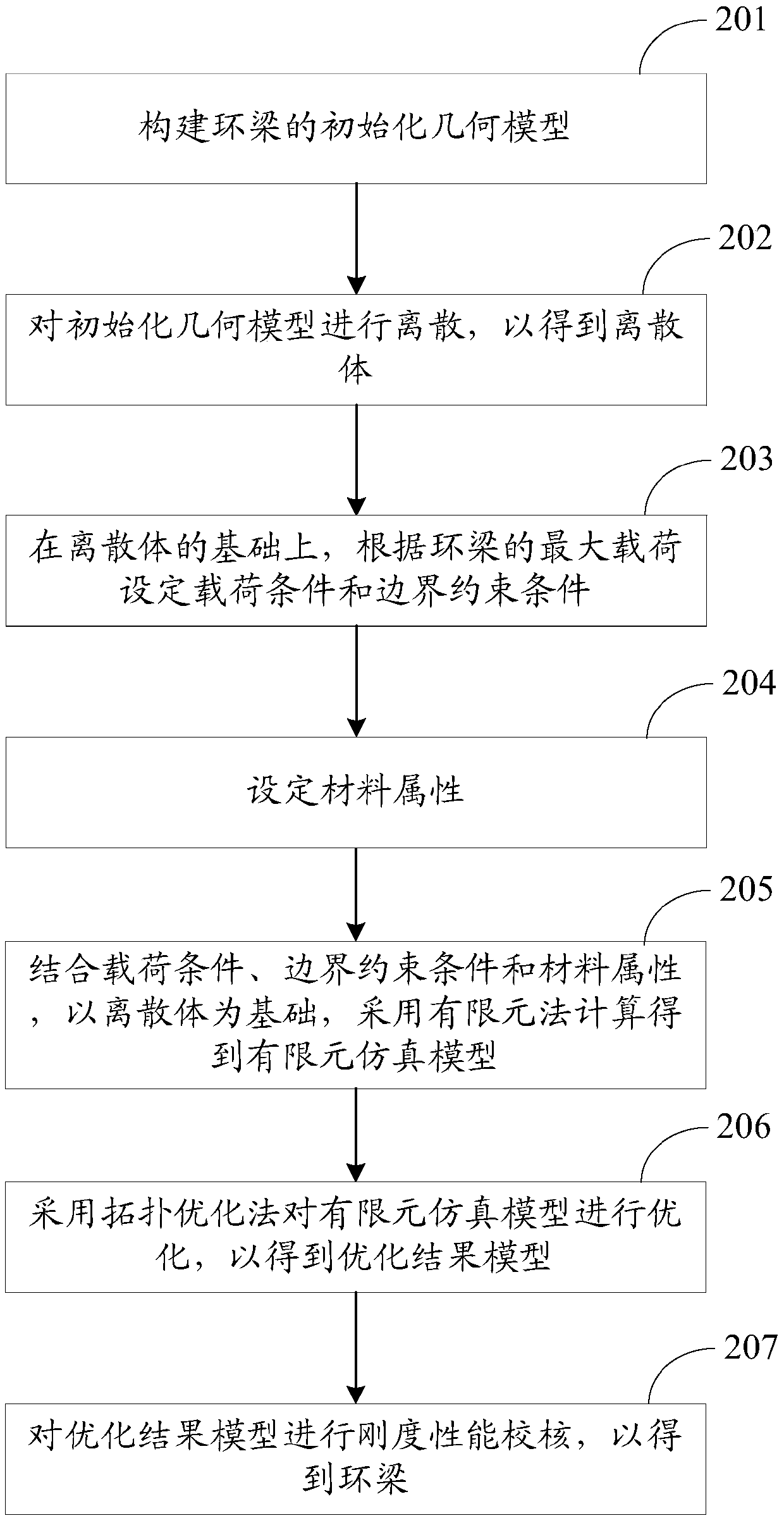

[0046] Another design method of the crane ring beam provided by the embodiment of the present invention, such as figure 2 As shown, the design method includes:

[0047] Step 201: Construct an initial geometric model of the ring beam.

[0048] In this way, the basic profile of the ring beam can be determined, which provides an optimization basis for step 202 .

[0049] Specifically, according to the structure of the ring beam, the size parameters of the ring beam are determined, and the initial geometric model of the ring beam is constructed according to the size parameters of the ring beam. Among them, the size parameter can be the outline dimension and functional dimension of the ring beam, the outline dimension can be specifically the length, width and height of the ring beam, etc., the functional dimension can be specifically the size of the ring beam assembly, and the assembly can be specifically For the mounting holes and leg sockets of the ring beam, please refer to t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com