Reactor clip structure

A reactor and clip technology, applied in electrical components, transformer/inductor components, transformer/inductor magnetic cores, etc., can solve the problems of inconvenient installation and maintenance, inconvenient processing and installation, and heavy clips. To achieve the effect of convenient installation and maintenance, various installation forms, and enhanced strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] Embodiments of the present invention are described in detail below:

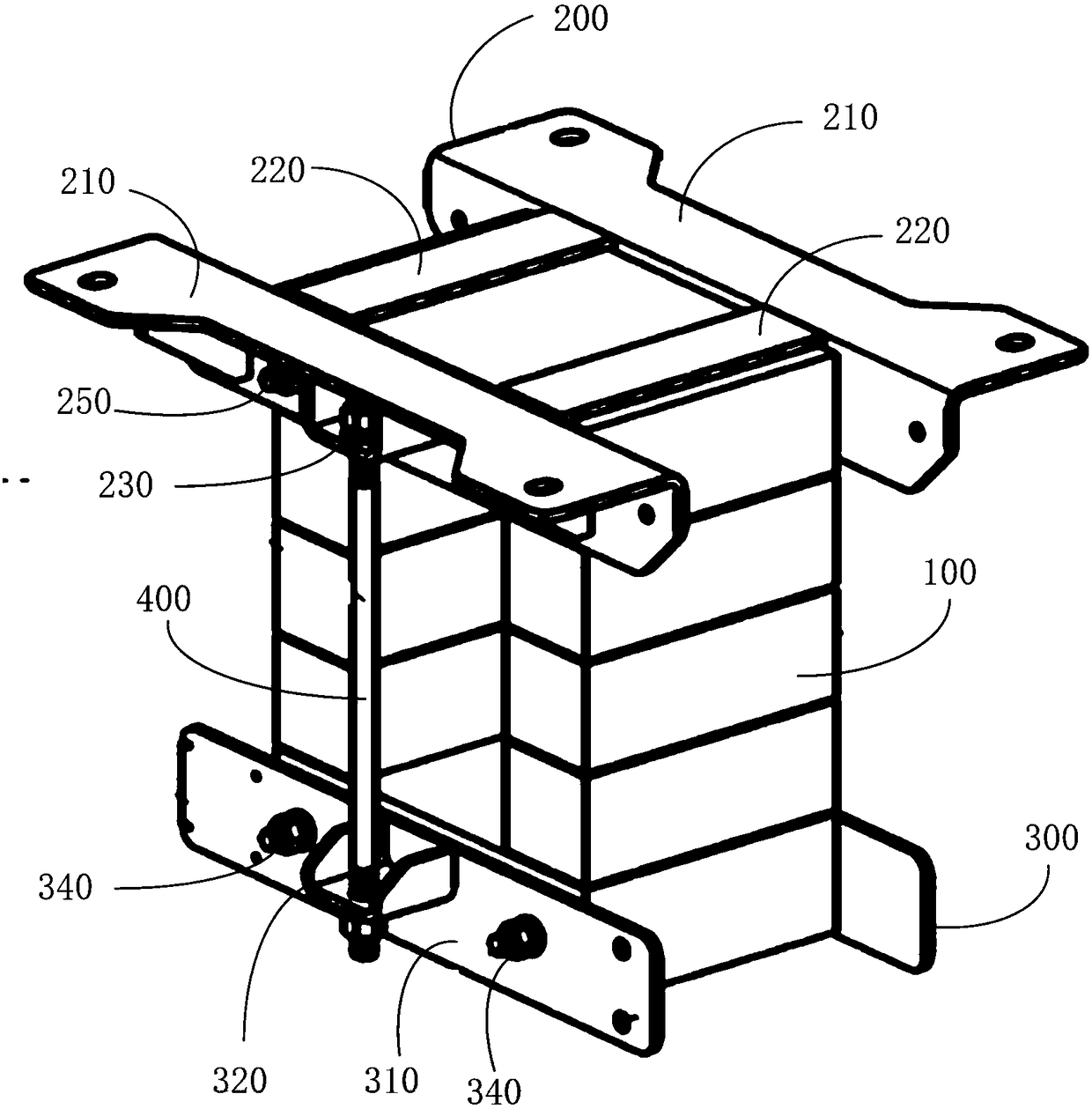

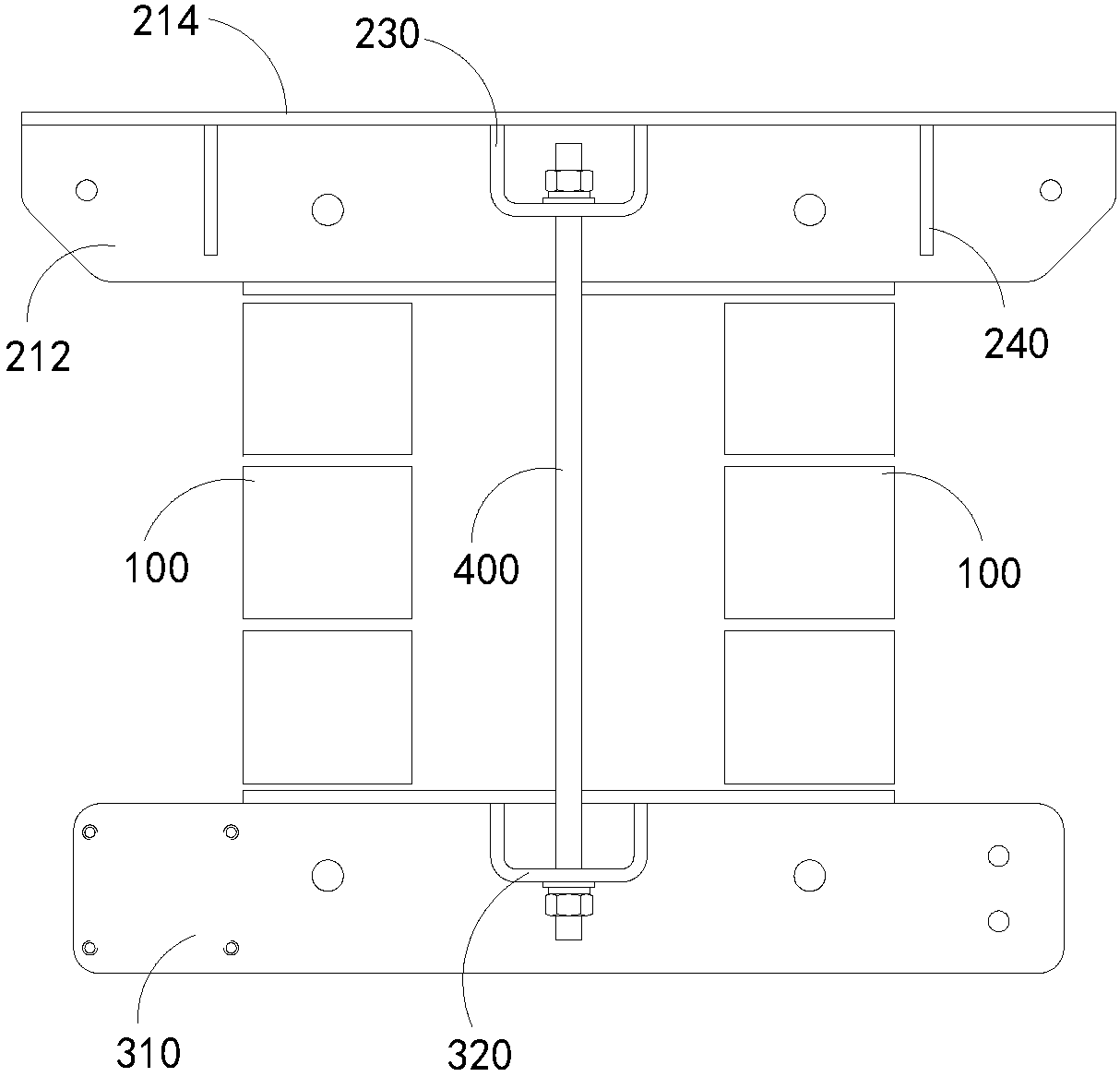

[0035] Such as figure 1 As shown, a clamp structure of a reactor includes an iron core 100, a first clamp 200 and a second clamp 300 respectively fixed at both ends of the iron core 100, and the first clamp 200 and the second clamp are fixed The clip fastener 400 of the piece 300. The first clip 200 and the second clip 300 are respectively clamped from both ends of the iron core 100, and the clip fastener 400 firmly connects the first clip 200 and the second clip 300, thereby clamping the iron core 100. prison.

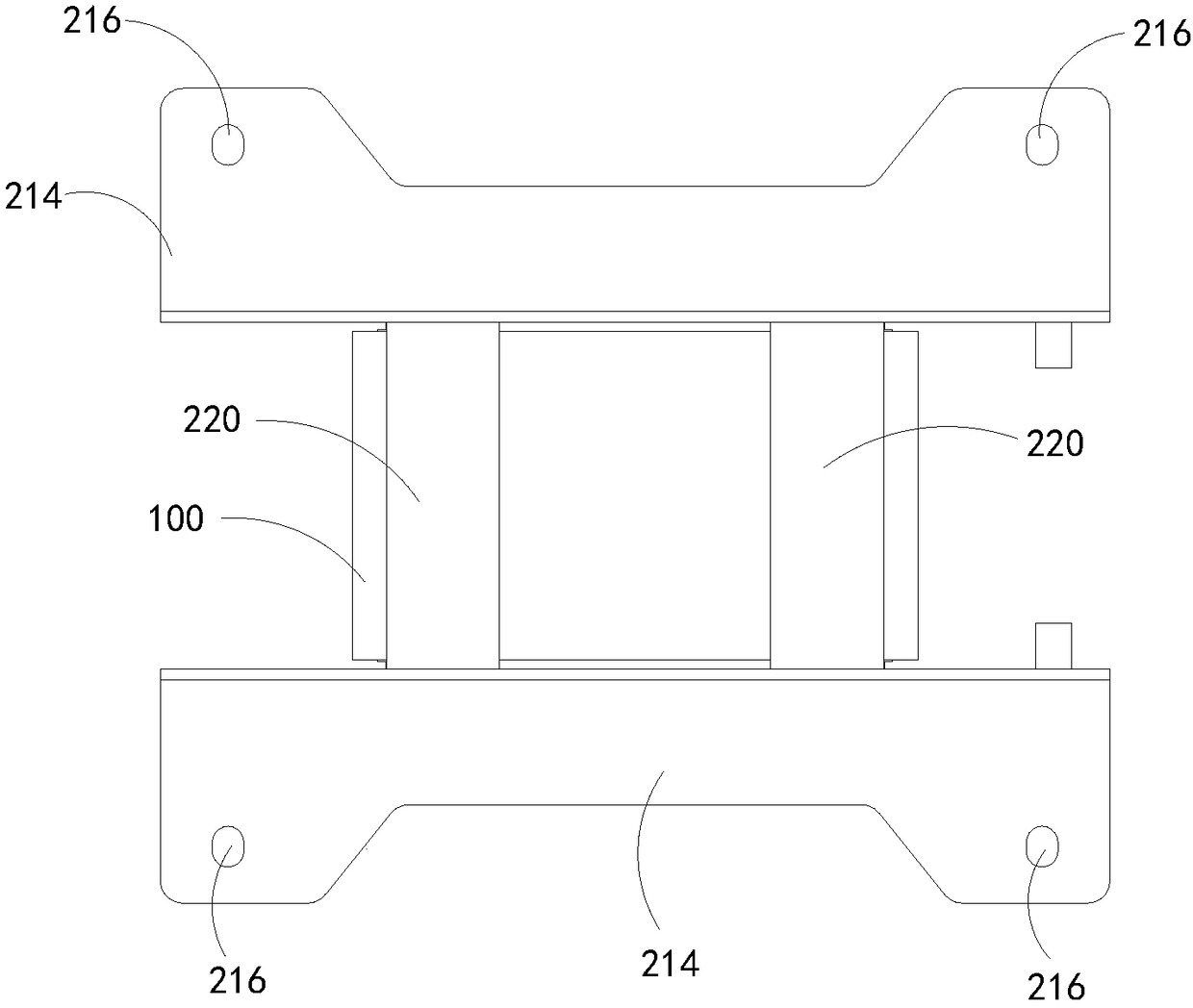

[0036] And, if Figure 1 to Figure 4 As shown, the core 100 includes opposite first side surfaces and second side surfaces, and opposite first end surfaces and second end surfaces located between the first side surfaces and the second side surfaces. Such as Figure 5 As shown, the first clip 200 includes two first clips 210 respectively arranged on the first side and the second side oppo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com