Manufacturing method of metal runners used for liquid cooling and liquid cooling metal runner cold plate

A technology of metal runners and manufacturing methods, which is applied in the direction of cooling/ventilation/heating transformation, electrical components, electrical equipment structural parts, etc., and can solve the problems of cold plate reliability and heat dissipation effect reduction, blocked flow passages, unreliable welding, etc. Problems, to achieve the effect of simple processing, avoid welding problems, and high reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

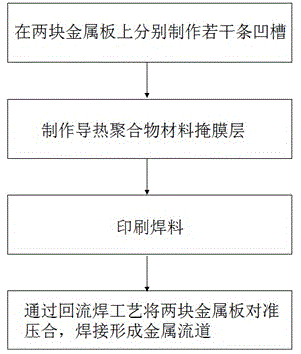

[0037] Such as figure 1 As shown, the method for manufacturing a metal runner for liquid cooling in the present invention comprises the following steps:

[0038] 1) Make several grooves on two metal plates;

[0039] This step can be realized by the following method.

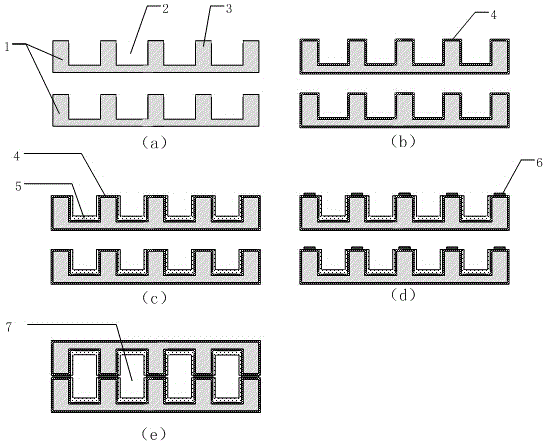

[0040] 1.1) Grooves 2 are made on two metal plates 1 by milling process or laser process ( figure 2 shown as four), and form (five) ribs 3, as figure 2 (a) shown. Wherein, the processing material of the metal plate 1 is 5A06 antirust aluminum, the depth of the groove 2 is about 2-10 mm, the width is about 5-8 mm, and the width of the rib 3 is about 2-5 mm.

[0041] 1.2) Pretreatment before electroplating: degrease in an alkaline degreasing solution at a temperature of 60°C-80°C, then soak in a rust remover for 15-30 minutes at a temperature of 15°C-35°C, and then use pure distilled water Rinse under high pressure for 8-12 minutes until the monitored pH of the effluent distilled water is 6-8.

[0042] 1.3)...

Embodiment 2

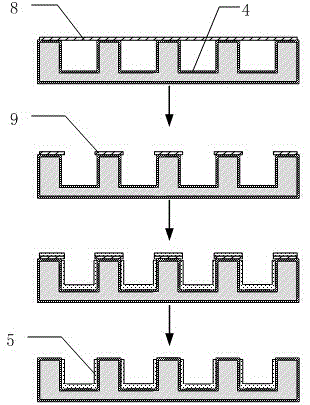

[0052] Embodiment 2 is basically the same as Embodiment 1, including four major steps, the difference lies in the method of making a thermally conductive polymer material mask layer in step 2).

[0053] In step 2) of Example 2, first paste the dry film 8 on the groove surface of the metal plate as a whole, and then make the dry film pattern 9 through exposure and development, that is, only leave the dry film on the ribs, and then spray thermally conductive polymerization on the concave surface as a whole Finally remove the dry film on the ribs and the thermally conductive polymer material on the dry film, leaving only the inside of the groove and forming a thermally conductive polymer material mask layer 5, such as image 3 shown. After the thermally conductive polymer material mask layer is fabricated, solder printing is performed on the ribs and metal runners are formed by welding.

[0054] The liquid-cooled metal runner cold plate includes two metal plates with the same st...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com