A sound-absorbing bowl and its noise-reducing relay

A relay and noise-reducing technology, which is applied in the field of sound-absorbing bowls and their noise-reducing relays, can solve problems such as poor effect of noise elimination, limited displacement, and large impact force, and achieve increased time, reduced impact force, and eliminated The effect of collision noise

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

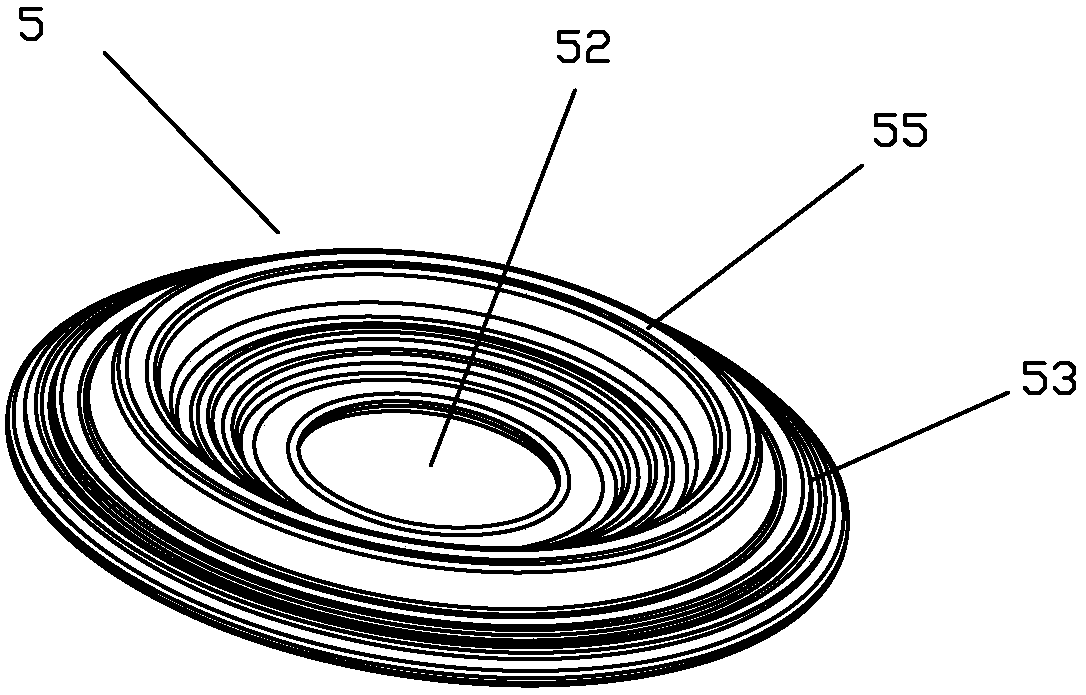

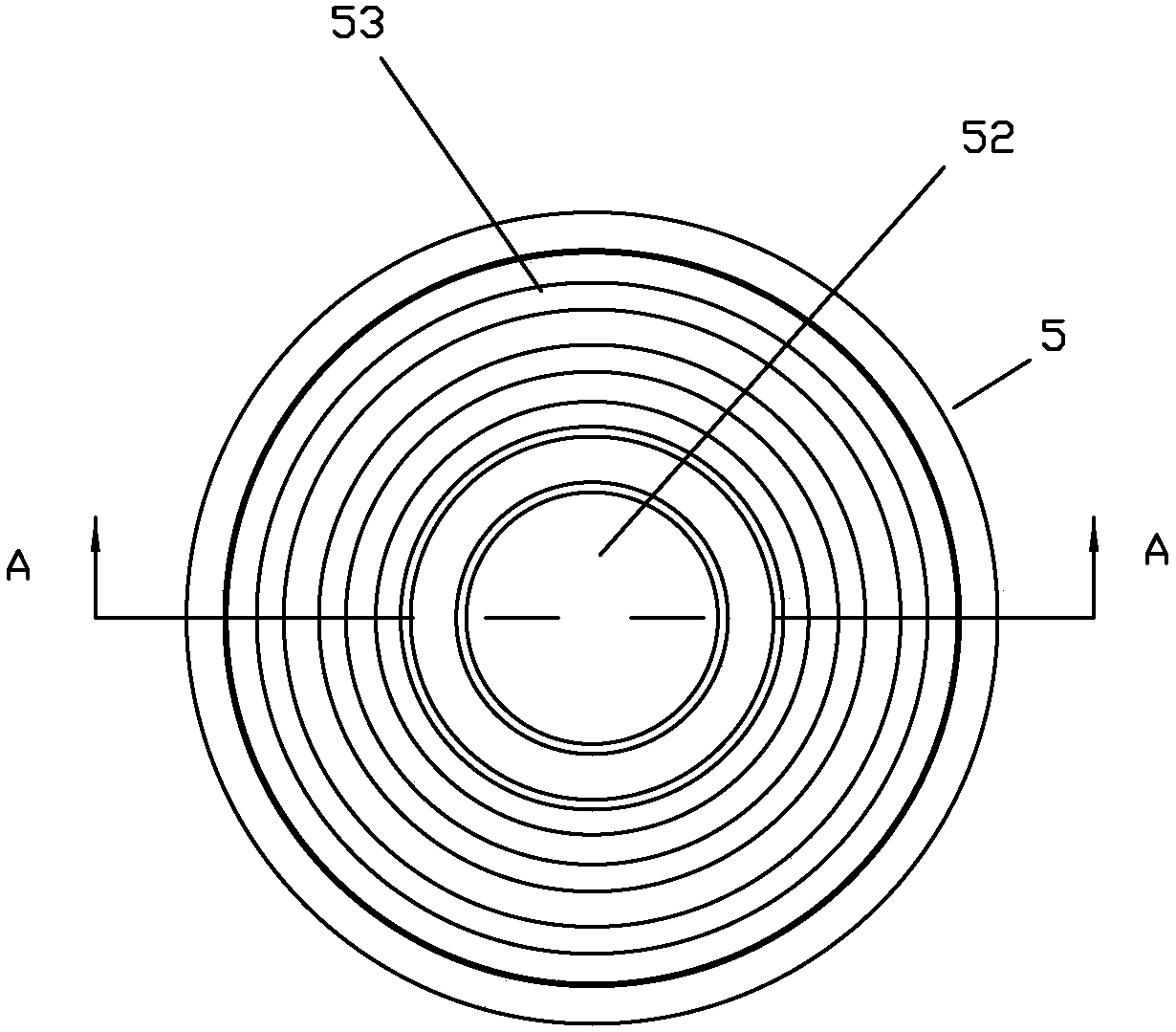

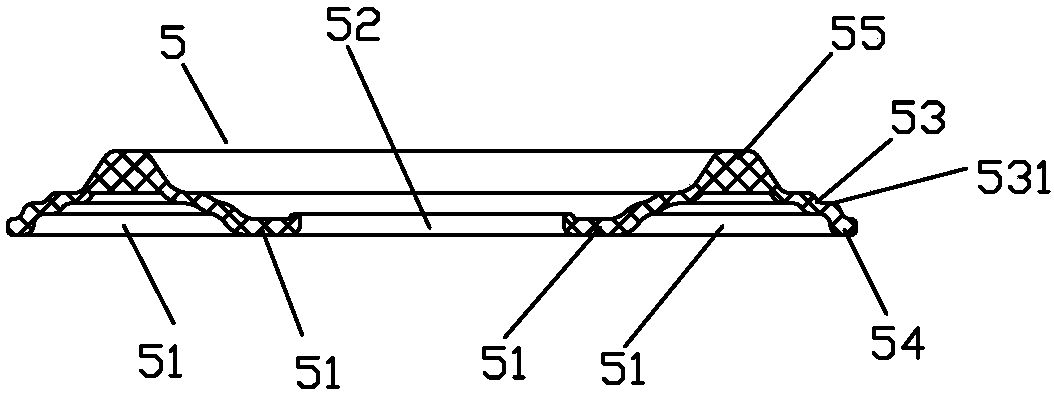

[0034] see Figure 1 to Figure 3 As shown, a sound-absorbing bowl of the present invention is arranged between the movable part and the fixed part and is installed on the fixed part. The sound-absorbing bowl 5 is set as an arc-shaped structure and has a horn-shaped opening 51; An abutting portion 54 is provided at one end toward the fixed part, a contact portion 55 is provided at one end toward the movable part, and a buffer portion 53 is set between the contact portion 55 and the mounting portion 54; when the movable part moves toward the fixed part , the movable part is in contact with the contact portion 55 of the sound-absorbing bowl and presses the contact portion 55 against the fixed part, so that the buffer portion 53 of the sound-absorbing bowl is deformed.

[0035] In this embodiment, the thickness of the contact portion 55 is greater than the thickness of the abutting portion 54 and also greater than the thickness of the buffer portion 53 .

[0036] In this embodime...

Embodiment 2

[0042] see Figure 4 As shown, a sound-absorbing bowl of the present invention differs from Embodiment 1 in that the contact portion 55 of the sound-absorbing bowl 5 is arranged on the opening edge corresponding to the trumpet-shaped opening 51, and the abutment portion 54 is arranged on the corresponding At the tip of the trumpet-shaped opening 51.

Embodiment 3

[0044] see Figure 1 to Figure 3 , Figure 5 to Figure 9 As shown, a noise reduction relay of the present invention includes a moving iron core 1, a static iron core 2, a push rod part 3 and a yoke 4; the push rod part 3 includes a push rod 31 and a moving spring mounting seat 32, The push rod 31 is passed through the middle hole 21 of the static iron core 2, one end of the push rod 31 is fixed to the moving iron core 1, and the other end of the push rod 31 is fixed to the moving spring mount 32; the yoke 4 It is fixed in one end face of the static iron core 2, and this end face is facing the moving spring mounting seat 32; The noise reduction bowl 5 as described in Embodiment 1 is used to eliminate the noise when the moving spring mounting seat 32 contacts and collides with the yoke 4, and the abutting portion 54 of the noise reduction bowl 5 is attached to the plate of the yoke 4 noodle.

[0045] A through hole 52 is also provided in the middle of the sound-absorbing bowl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com