Structured high-gain reflecting solder strip for solar cell panel

A technology of solar cells and reflective ribbons, which is applied in the direction of circuits, electrical components, semiconductor devices, etc., can solve the problems of insufficient tension of ribbons and solar cells, low reflective efficiency, and inability to bond and weld solar cells, etc., to achieve reduction Effects of current loss, distance reduction, and module power improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The specific implementation manners of the present invention will be further described below in conjunction with the accompanying drawings, so as to make the technical solution of the present invention easier to understand and grasp.

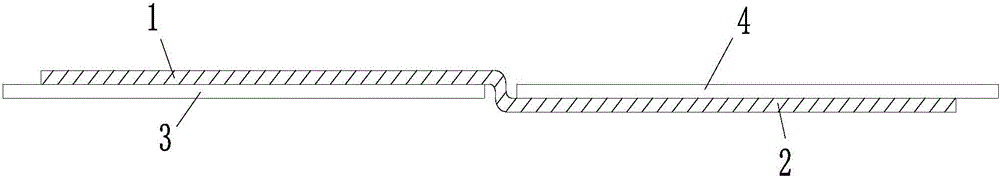

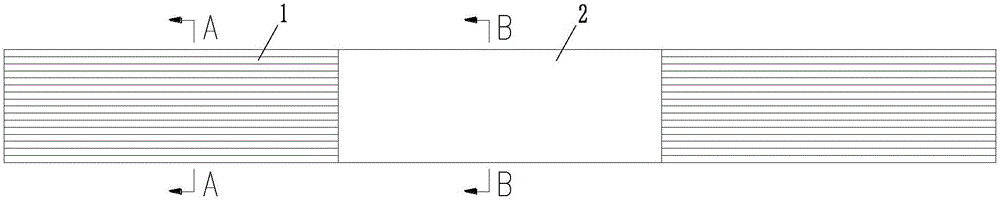

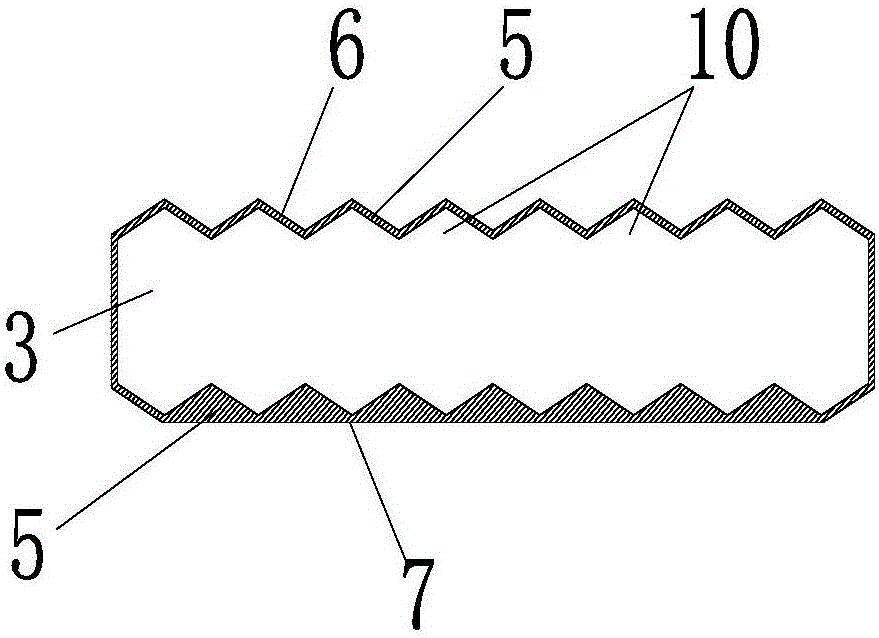

[0023] Such as Figure 1 to Figure 4 As shown, a structured high-gain reflective ribbon for solar cells includes A-section ribbon 1 and B-section ribbon 2 arranged at intervals, and the A-section ribbon 1 and the A-section ribbon 1 are arranged below The main grid line of the first battery sheet 3 is welded and connected, and the B-segment ribbon 2 is welded and connected to the back electrode of the second battery sheet 4 arranged above the B-segment ribbon 2, wherein the A-segment ribbon 1 and The section B solder strip 2 correspondingly includes a section A copper substrate 3 and a section B copper substrate 4 connected to each other, and the outer surfaces of the section A copper substrate 3 and the section B copper substrate 4 are re...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com