Silica gel diaphragm, preparation method, and sounding part

A technology of silicone diaphragm and sound-generating components, which is applied in the field of loudspeakers, can solve the problems of high cost, complex molding, and low efficiency, and achieve better and better fidelity effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

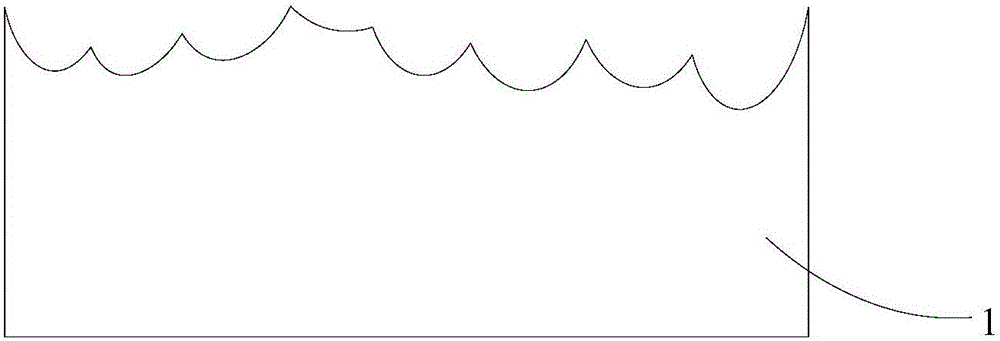

[0033] Step 1: The preparation method of the silica gel diaphragm comprises the following steps:

[0034] Step 2: providing a silica gel membrane 4;

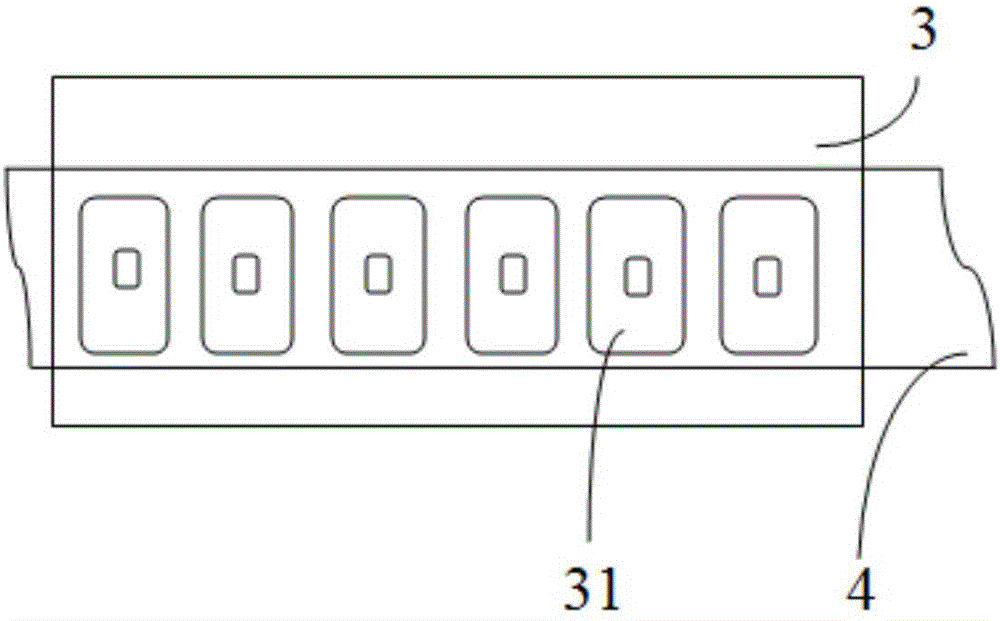

[0035] Step 3: The silicone film 4 is continuously introduced into the mold cavity 31 of the molding machine 3;

[0036] Step 4: Close the mold and control the mold temperature;

[0037] Step 5: Adjust the molding pressure and maintain the pressure for a period of time, so as to realize the secondary molding of the silicone membrane 4;

[0038] Step 6: Take out the silicone diaphragm 1 after forming, the thickness of the silica gel diaphragm 1 is not uniform.

[0039] It can be understood that the silica gel film used in the embodiment of the present invention is a substrate-free silica gel film, and the method for preparing the silica gel diaphragm used in the embodiment of the present invention is to perform secondary molding with the substrate-free silica gel film that has been preliminarily manufactured. Methods.

[0040...

Embodiment 1

[0050] This embodiment provides a method for preparing a silica gel diaphragm, which includes the following steps in sequence:

[0051] Step 1: providing the formed silicone film 4;

[0052] Step 2: introducing the formed silicone film 4 into the mold cavity 31 of the molding machine 3 in a continuous manner, so that the silicone film 4 is kept flat in the mold cavity 31;

[0053] Step 3: Clamp the upper and lower molds or left and right molds, and control the temperature of the upper and lower molds or the left and right molds to 155°C;

[0054] Step 4: Adjust the molding pressure to 20MPa;

[0055] Step 5: Hold the pressure for 1 minute;

[0056] Step 6: Take out the molding and prepare the silicone diaphragm 11 .

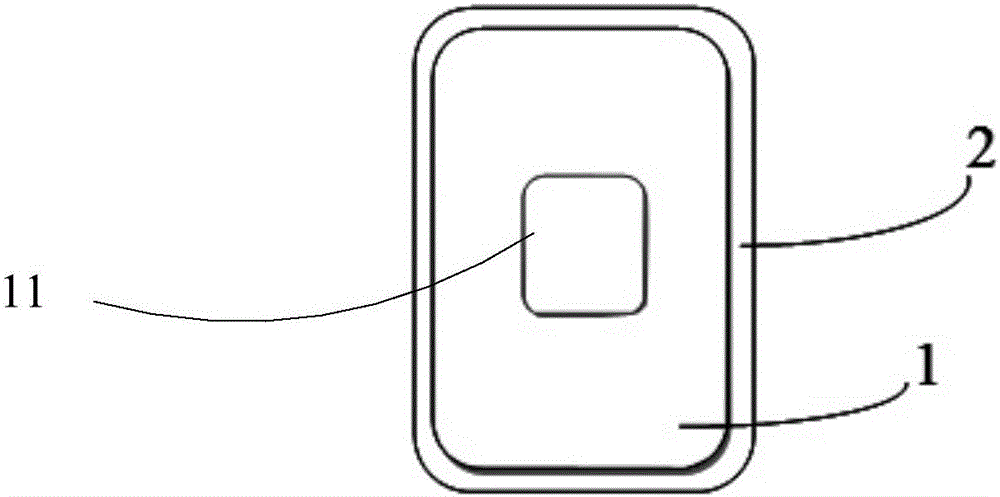

[0057] Such as image 3As shown, the silicone diaphragm 1 after secondary molding can be fixed on the sound-generating part 2 of the electronic speaker. Further, the processed silicone diaphragm 1 can be fixed in the cavity of the sound-generating part 2 of ...

Embodiment 2

[0059] This embodiment provides a method for preparing a silica gel diaphragm, which includes the following steps in sequence:

[0060] Step 1: providing the formed silicone film 4;

[0061] Step 2: introducing the formed silicone film 4 into the mold cavity 31 of the molding machine 3 in a continuous manner, so that the silicone film 4 is kept flat in the mold cavity 31;

[0062] Step 3: Clamp the upper and lower molds or left and right molds, and control the temperature of the upper and lower molds or the left and right molds to 160°C;

[0063] Step 4: Adjust the molding pressure to 21MPa;

[0064] Step 5: Hold the pressure for 1 minute;

[0065] Step 6: Take out the molding and prepare the silicone diaphragm 1 .

[0066] Such as image 3 As shown, the silicone diaphragm 1 after secondary molding can be fixed on the sound-generating part 2 of the electronic speaker. Further, the processed silicone diaphragm 1 can be fixed in the cavity of the sound-generating part 2 of ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com