True density measurement device

A measuring device and a technology of true density, applied to the measuring device, by measuring the pressure difference to determine the specific gravity, the specific gravity measurement and other directions, can solve the problem of not using the structure of the expansion chamber volume can be changed, and achieve the effect of improving the measuring accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

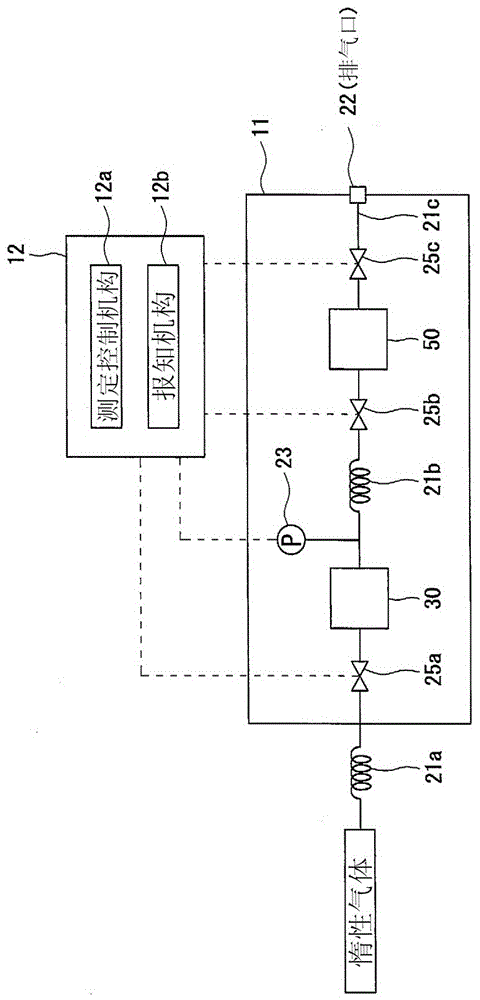

Method used

Image

Examples

Embodiment Construction

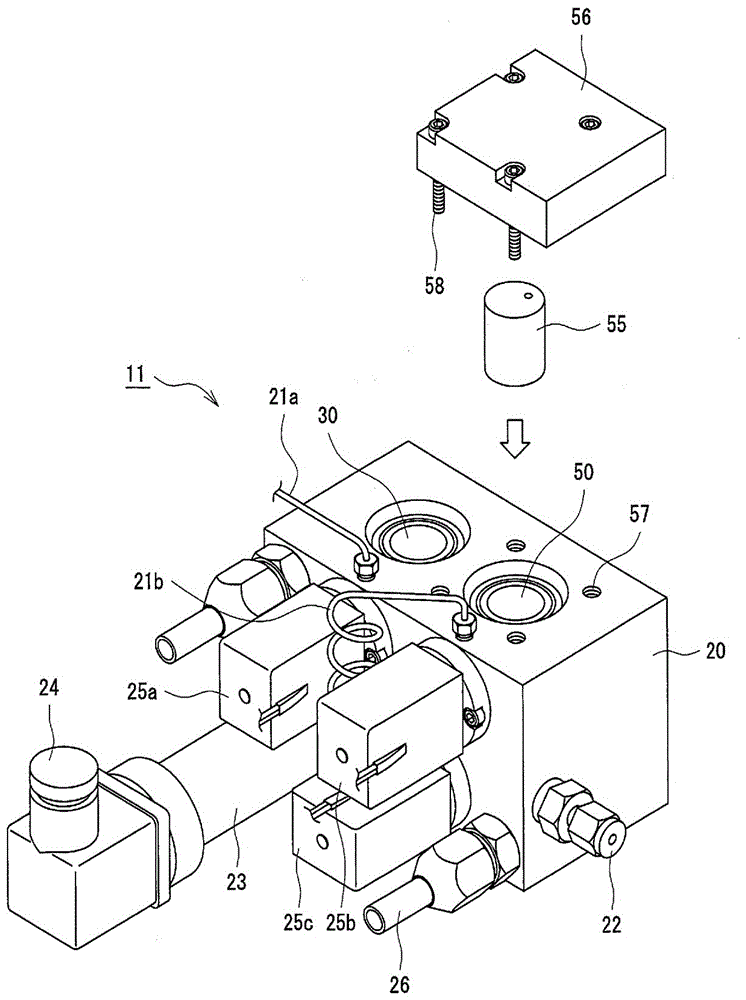

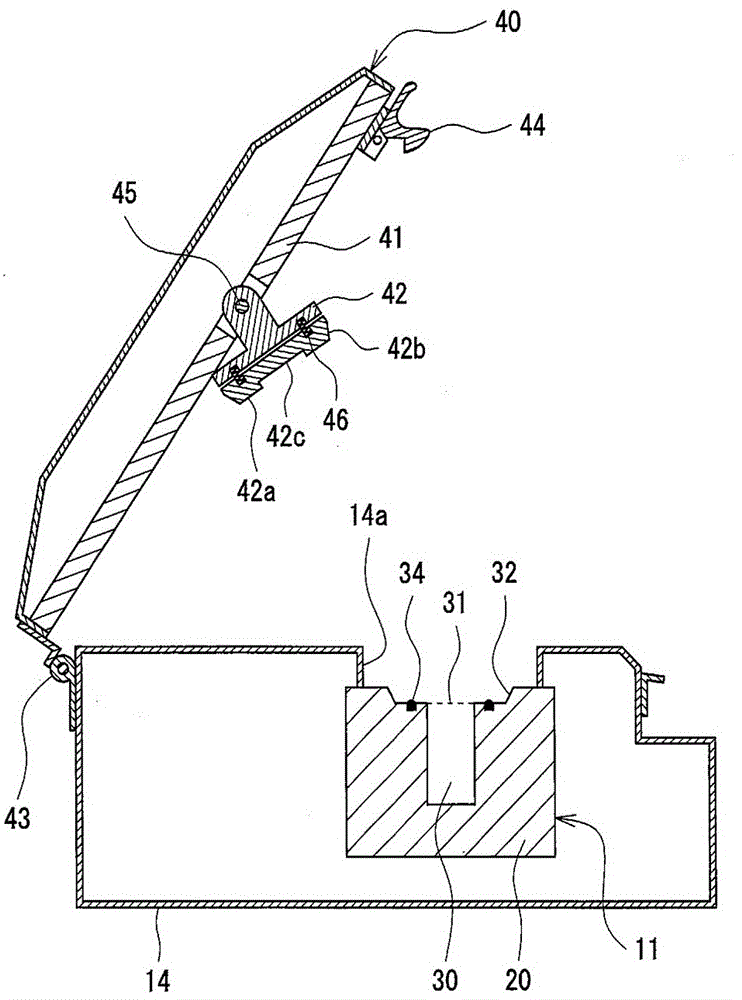

[0028] The inventors of the present invention made it possible to change the volume of the expansion chamber to further improve the measurement accuracy. Since it is easier to enter the expansion chamber, the operator can change the volume of the expansion chamber through the simple operation of moving the volume changing member in and out, which can greatly improve the measurement accuracy without causing the disadvantages of increasing the size and cost of the device. .

[0029] In the true density measuring device as an example of the embodiment, the expansion chamber and the sample chamber open in the same direction.

[0030] In a true density measuring device as an example of an embodiment, the true density measuring device has a block in which the sample chamber and the expansion chamber are provided respectively, and the opening of the expansion chamber and the opening of the sample chamber Openings are respectively formed on the upper surfaces of the blocks.

[0031]...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com