Draining handle sleeve

A technology of grips, arrangement and combination, applied in the field of grips, which can solve the problems of embrittlement, cracking, non-absorption, and discomfort of users

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

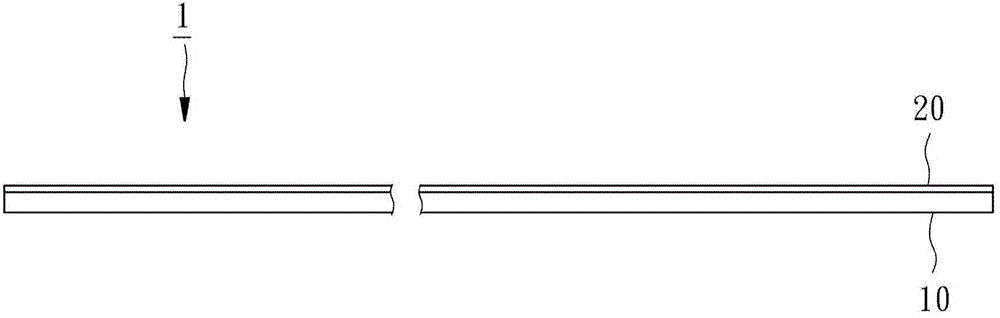

[0037] The structure and characteristic effects of the present invention will be described in detail below through the enumerated embodiments and accompanying drawings. First of all, in the various embodiments and drawings described below, the same reference numerals represent the same or similar elements , component, object, structure or device, firstly describe.

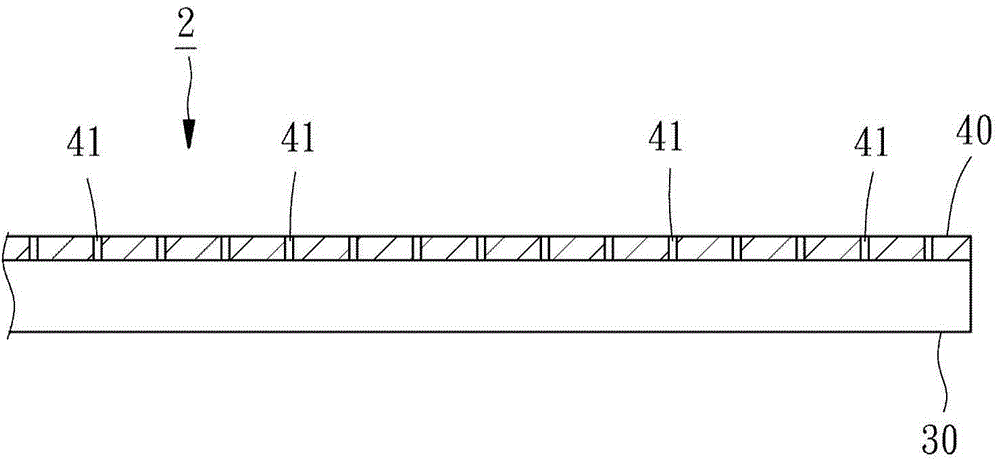

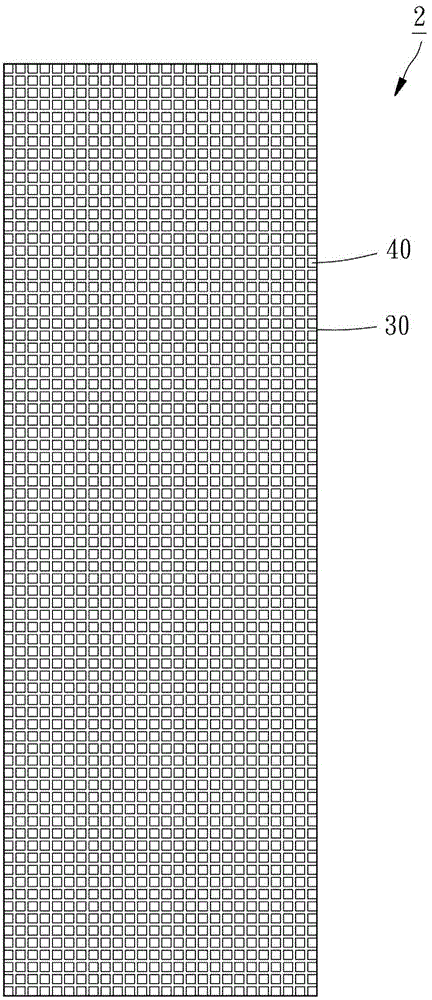

[0038] Please see first Figure 2 to Figure 3 , is a grip cover 2 for guiding and draining liquid provided by the first preferred embodiment of the present invention, which includes:

[0039] A bottom layer 30 and a top layer 40 located on one side of the bottom layer 30 are formed, and at least one drain hole 41 is perforated from the top layer 40 toward the bottom layer 30; and in the first preferred embodiment of the present invention , the top layer 40 is provided with a plurality of guiding holes 41 arranged in an array.

[0040] Wherein, the bottom layer 30 mainly includes but is not limited to materials or...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com