Lint filter capable of self cleaning and lint cleaning method thereof

A lint filter and self-cleaning technology, applied in the field of clothes dryers, can solve the problems of not being able to be taken out, affecting the performance of clothes dryers, breeding bacteria, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

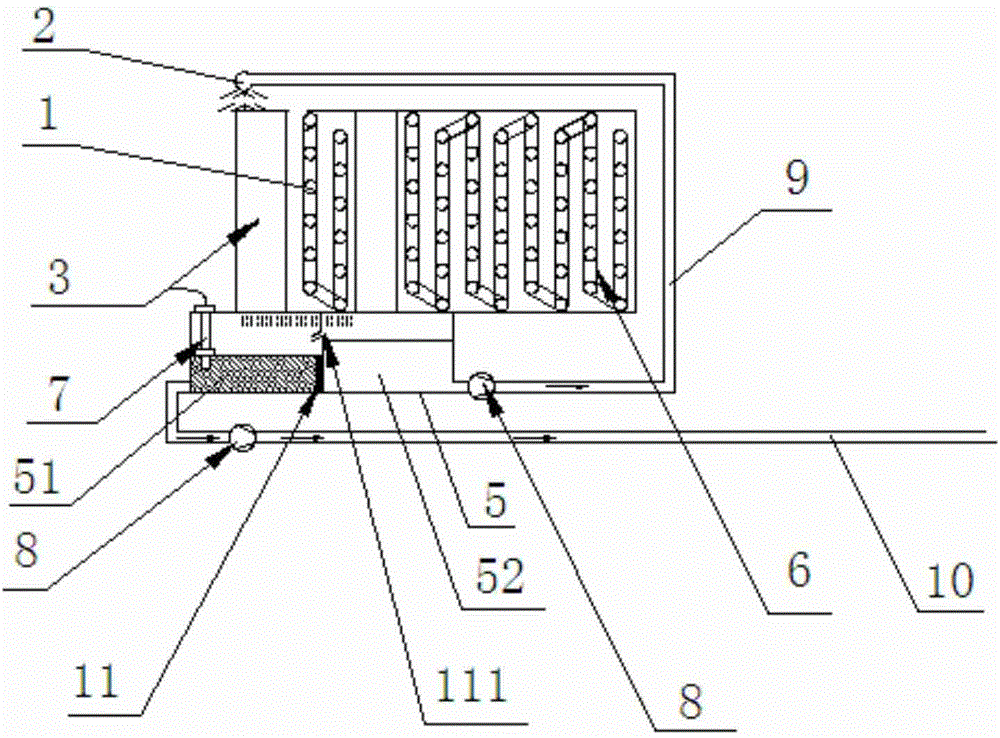

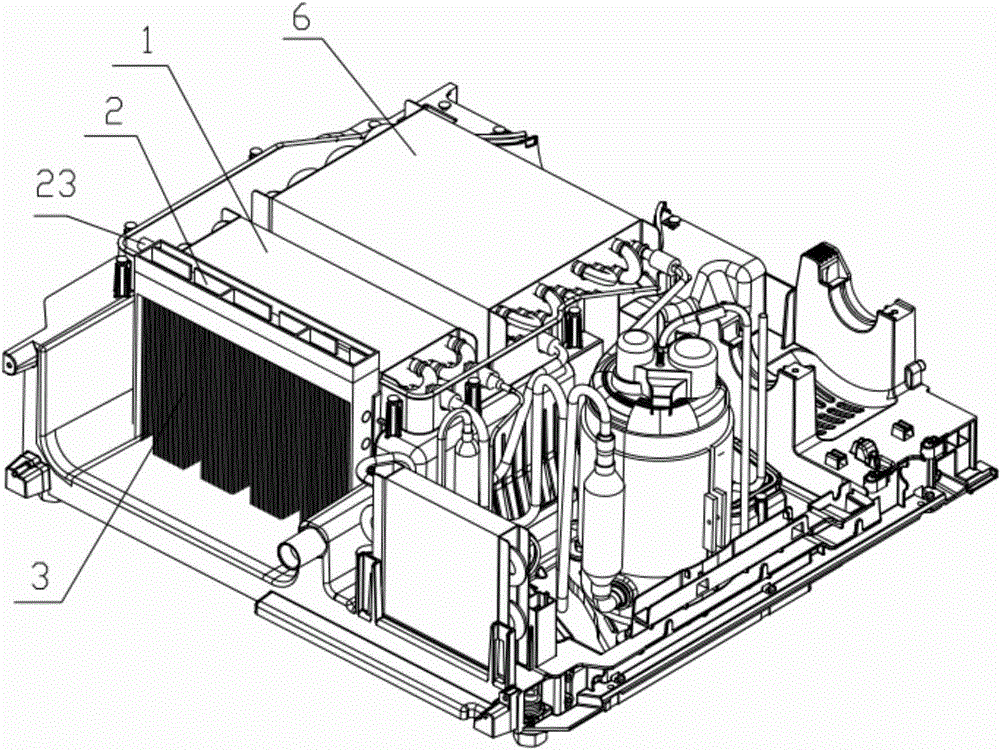

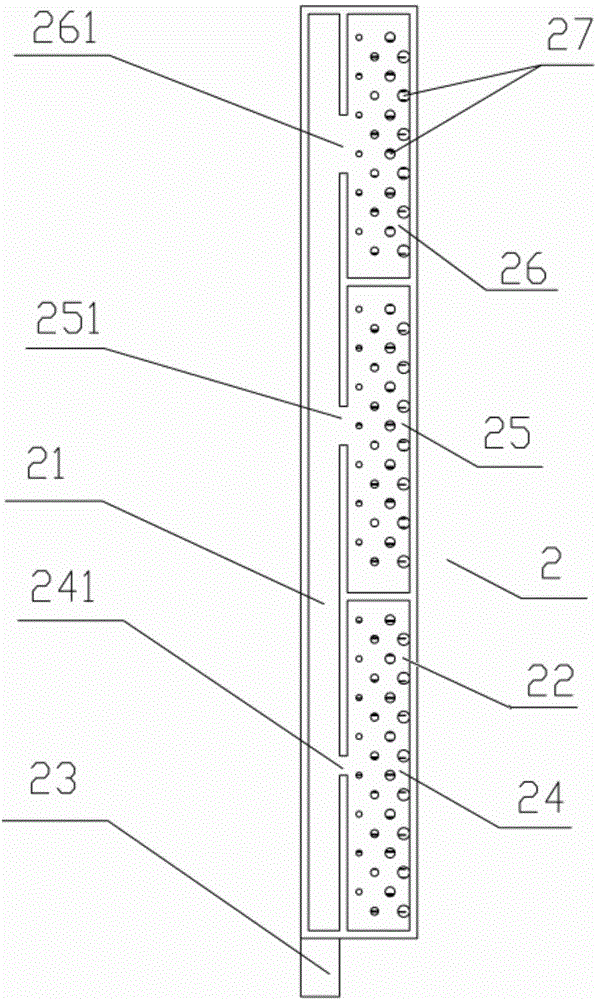

[0028] A self-cleaning lint filter includes a filtering device and a flushing device, the flushing device is located above the filtering device and the two are connected by plugging, and the two are detachable to separate the filtering device from the flushing device. The flushing device covers the largest cross-section of the filter device, and can wash the entire filter device from top to bottom. The lint filter is detachably installed at the front end of the windward side of the evaporator in the air circulation channel of the clothes dryer.

[0029] The part of the flushing device exceeds the windward side of the filter device, and the flushing device can flush the liquid to the windward side of the filter device.

[0030] The flushing device includes a water spray device with a plurality of water spray holes at the bottom, the water spray device has a cavity, the cavity communicates with the water spray hole, the water spray device is installed on the top of the filter dev...

Embodiment 2

[0054] The method for cleaning lint from a clothes dryer described in this embodiment is implemented on the device described in Embodiment 1.

[0055] A condensed water collection box having two cavities, a first cavity and a second cavity, is arranged below the lint filter and the evaporator of the clothes dryer, and the two cavities are respectively close to the lint filter and the evaporator.

[0056] The second chamber collects the condensed water generated by the evaporator, and uses pipes to transport the condensed water collected in the second chamber to the water spray device above the filter device of the lint filter to rinse the filter device of the clothes dryer to remove the adhesion lint on it. Use the water spray device to spray water from top to bottom to flush the filter device and remove the lint on it. The water spray device should spray water on the front of the windward side of the filter device to remove the lint on the windward side of the filter device a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com