Intelligent design of new-type line-contact space-meshing beveloid gear

A thickening gear, line contact technology, applied in the direction of components with teeth, belts/chains/gears, mechanical equipment, etc., can solve the problems of gear pair damage, short service life, large replacement, etc., to achieve power transmission. Large, widely used, the effect of improving the bearing capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

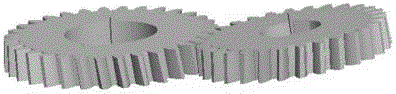

Image

Examples

Embodiment 1

[0011] An intelligent design of a new type of thickening gear with line contact space meshing, including the following steps: the so-called thickening gear is on different end sections of the gear, and its tooth profile has different coefficients of variation. The tooth surface of the standard involute thickened gear (the coefficient of variation changes linearly along the axial direction) is an involute helicoid, and the meshing between the involute helicoids in the case of intersecting axes and staggered axes is impossible to achieve line contact . In order to realize the line contact, the tooth surface equation of another conjugated gear 2 is deduced from the tooth surface equation of a known involute thickening gear 1 by using the space meshing principle. Then compare the gear with the standard involute thickening gear, calculate and analyze the shape difference of the two gears (that is, analyze the tooth shape difference and tooth direction difference), and use an approp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com