Optical Proximity Correction Method

A technology of optical proximity correction and exposure graphics, which is applied in optics, originals for photomechanical processing, instruments, etc., can solve the problems that semiconductor devices cannot meet the design size requirements and the graphics are too small, so as to avoid the loss of yield rate, Avoid pinching or bridging effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

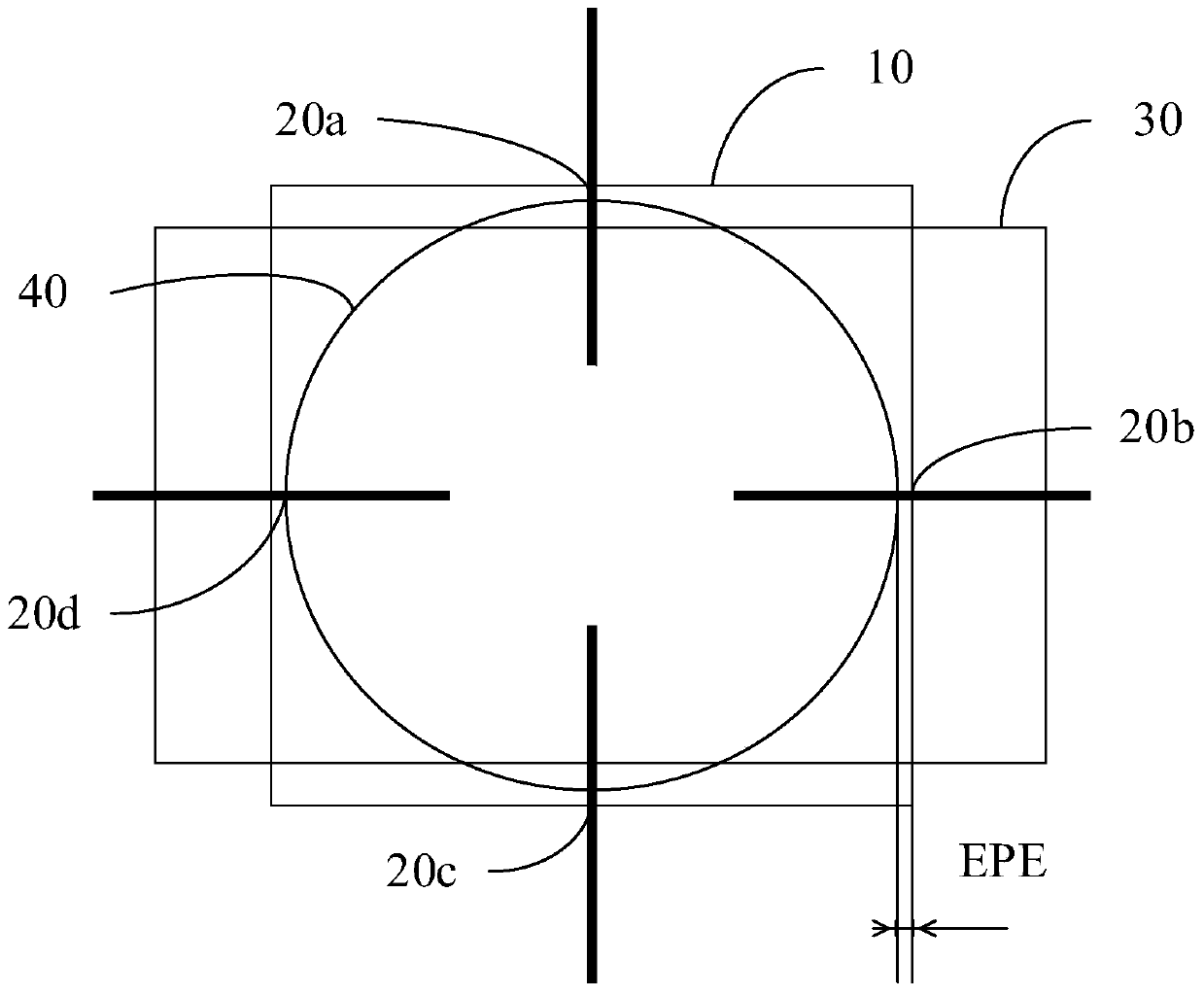

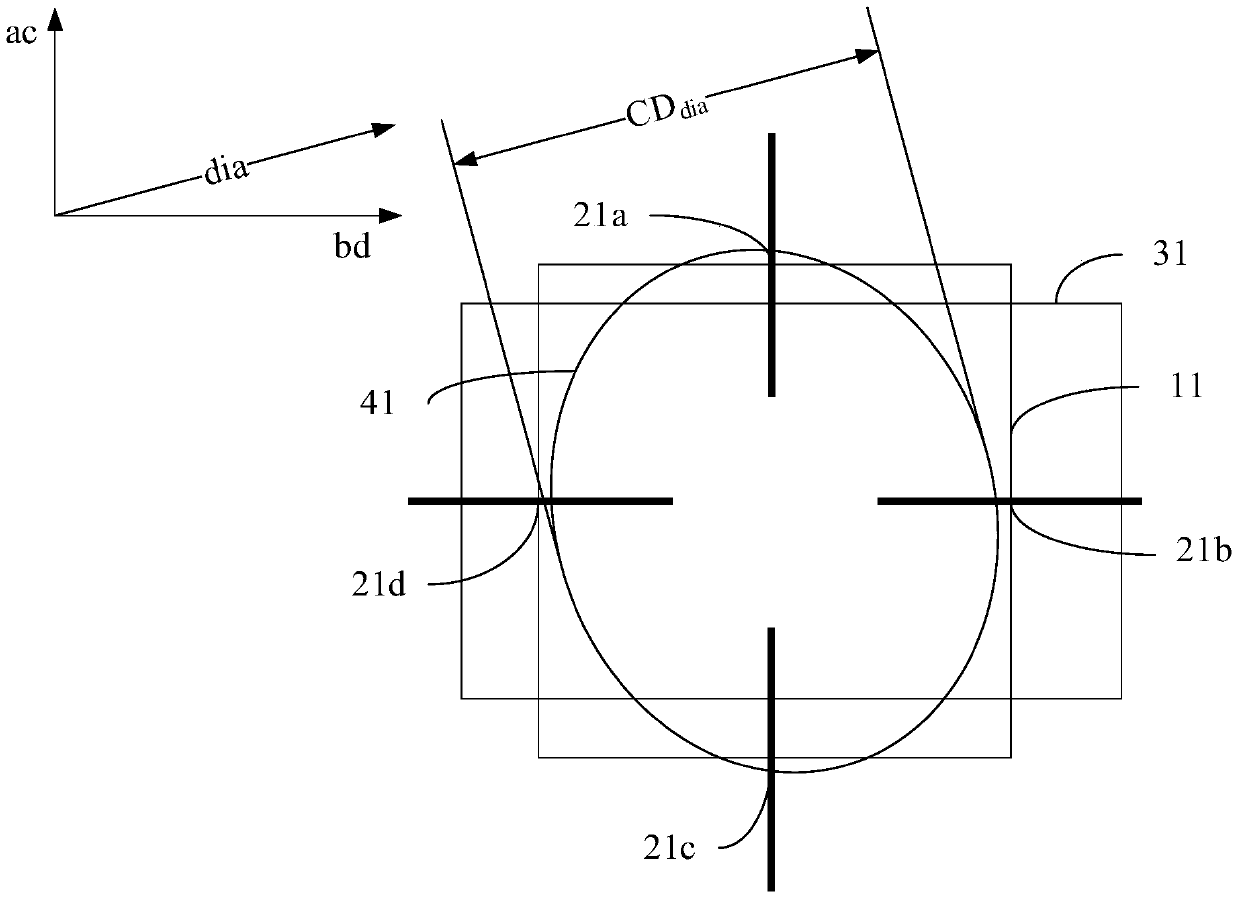

[0038] It can be known from the background art that the existing optical proximity correction technology has the problem that the formed semiconductor device cannot meet the design size requirement. Now, in combination with the existing technology, the optical proximity correction is performed on the pattern forming the contact hole to analyze the cause of the problem:

[0039]After the optical proximity correction is completed, if the edge position error in a certain direction reaches the standard, the size in this direction must also meet the design requirements. However, in the prior art, the method of taking a sampling point on each side of the target graphic, although after optical proximity correction, the size of the finally formed graphic in the direction of the sampling point must meet the design requirements. However, during the exposure process, the graphics may be distorted. When the graph is distorted, there may be an undersize problem in the direction where the ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap