Front windshield with high-definition camera area and manufacturing method

A high-definition camera and front glass technology, which is applied to windshields, image communications, and color TV components, can solve problems such as impact and optical distortion of the camera's field of view, reduce graphic distortion, improve imaging effects, and reduce The effect of power

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] In order to describe the technical content, the realized purpose and the effect of the present invention in detail, the present invention will be further described below in conjunction with the accompanying drawings and embodiments. Obviously, the described embodiments are only part of the embodiments of the present invention, not all of them. example.

[0035] In the present invention, the orientations or positional relationships indicated by the terms "upper", "lower", etc. are all based on the orientations or positional relationships shown in the drawings. These terms are mainly used to better describe the present invention and its embodiments, and are not used to limit the indicated devices, elements or constituents to have specific orientations, and thus should not be construed as limiting the present invention.

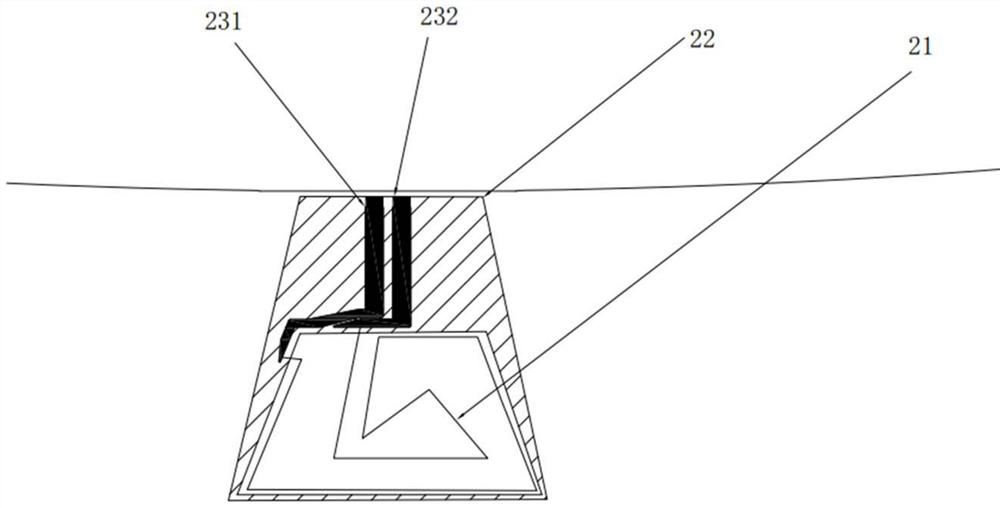

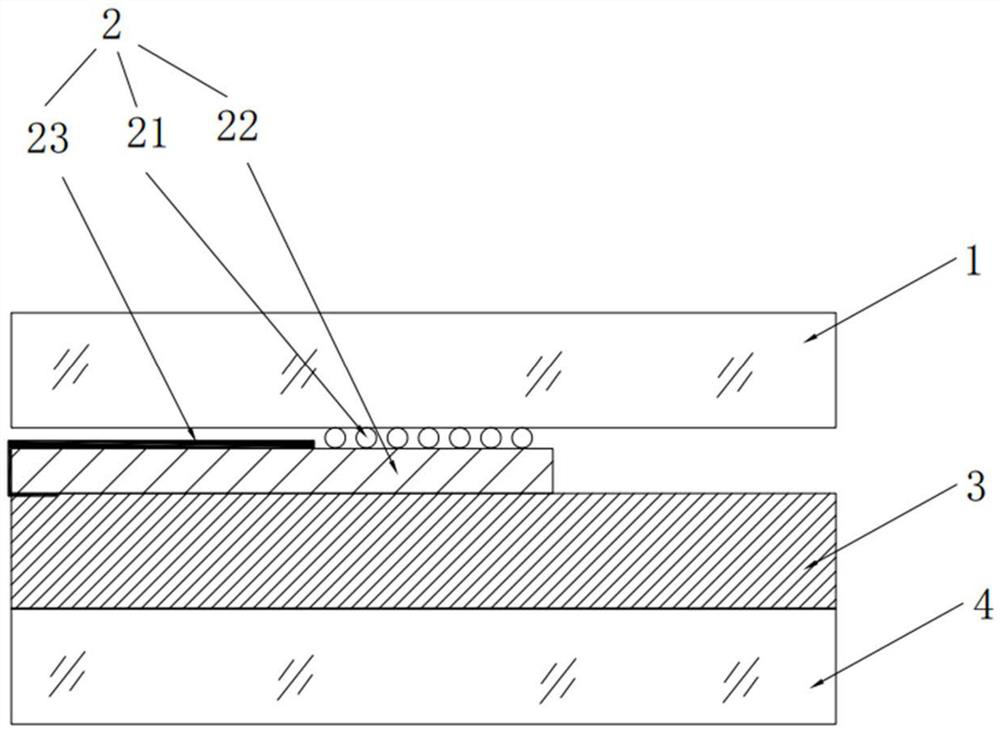

[0036] Such as Figure 1-Figure 2 As shown, the present invention is aimed at improving the imaging of the camera area located in the middle and upper p...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap