Fishing rod holder and fishing rod apparatus

A rod rack and rack body technology, applied in the field of fishing equipment, can solve the problems of easy shaking of fishing rods, inconvenient use, difficulty in adapting to different occasions, etc., and achieve the effects of lightening the burden, convenient use, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

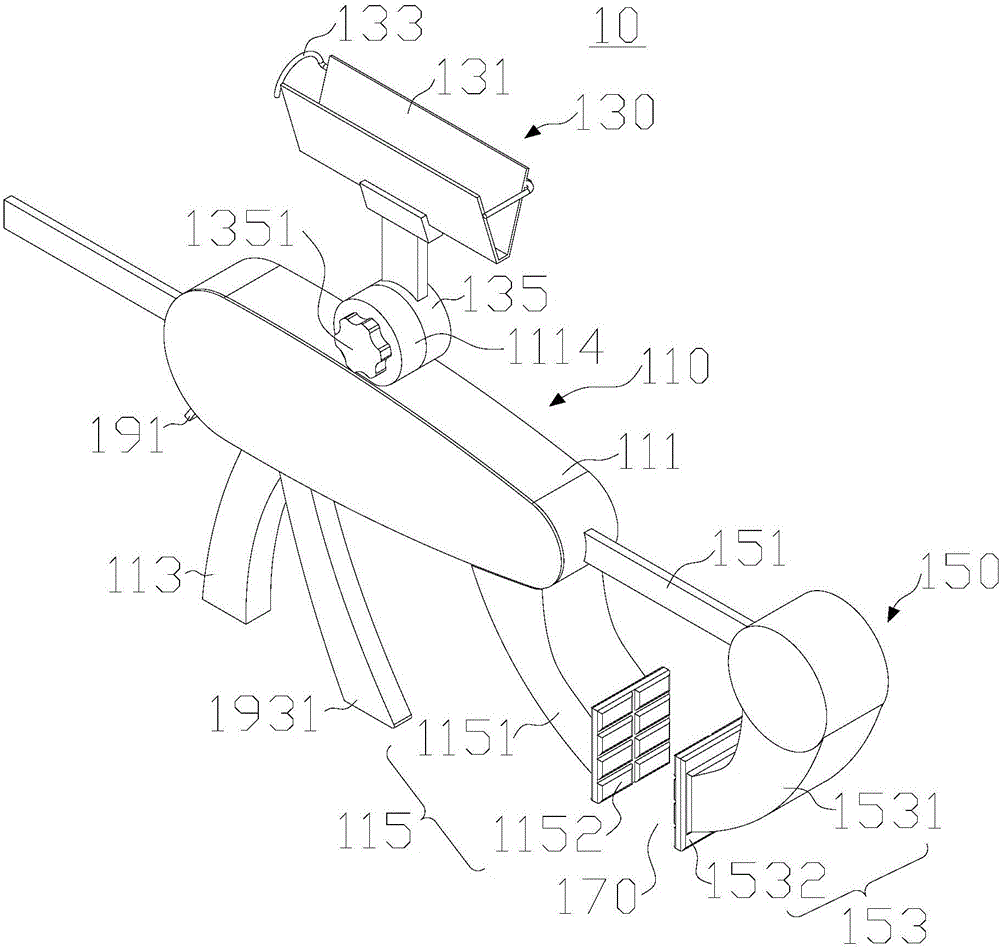

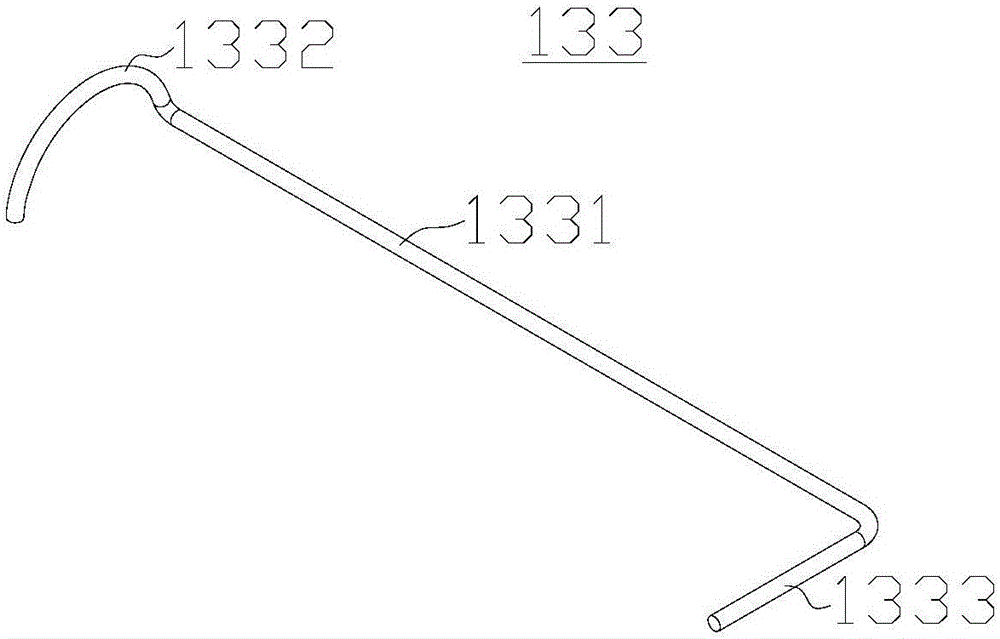

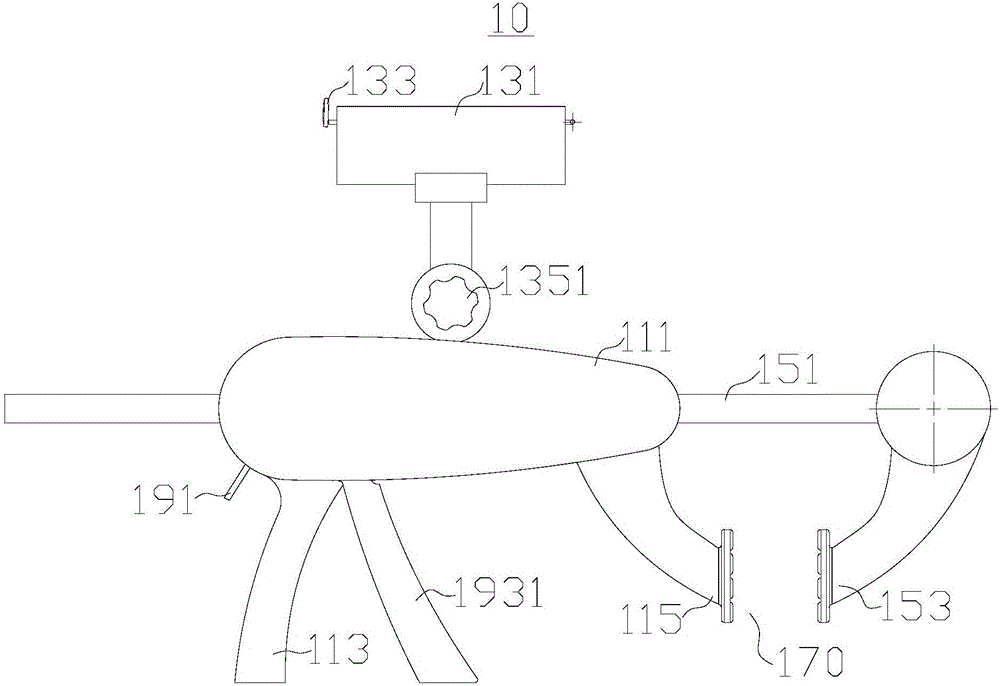

[0046] Please refer to figure 1 , image 3 , Embodiment 1 of the present invention provides a bridge fishing bracket 10 . Each part of bridge fishing support 10 is described in detail below:

[0047] The frame body 110 includes a main body 111, a handle 113 and a first clamping member 115. Both the handle 113 and the first clamping member 115 are fixedly arranged on the main body 111. The handle 113 is used for grasping. Between the handle 113 and the main body 111, the first The connection method between the clip 115 and the body 111 is not limited, for example, integral molding, welding, detachable connection and the like can be adopted.

[0048] In this embodiment, the first clamping part 115 includes a first connecting section 1151 and a first clamping part 1152, the first clamping section may be an arc-shaped piece, one end of the first clamping section is fixed to the body 111, the second The other end of a clamping section is fixedly connected to the first clamping p...

Embodiment 2

[0071] Correspondingly, Embodiment 2 of the present invention provides a bridge fishing device, which includes a fishing rod (not shown in the figure) and the bridge fishing bracket 10 in Embodiment 1. When in use, the bridge fishing bracket 10 Fix it on a fixed structure, and then put the fishing rod into the receiving groove 131 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com