Oolong tea indoor sun-drying processing technique

A processing technology and technology of oolong tea, applied in the directions of tea treatment before extraction, climate change adaptation, etc., can solve the problems of dust and dirt on leaves, difficulty in grasping the degree of drying, uneven drying, etc., so as to achieve uniform drying quality, Reduce the chance of uneven light and ventilation, and achieve uniform drying effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

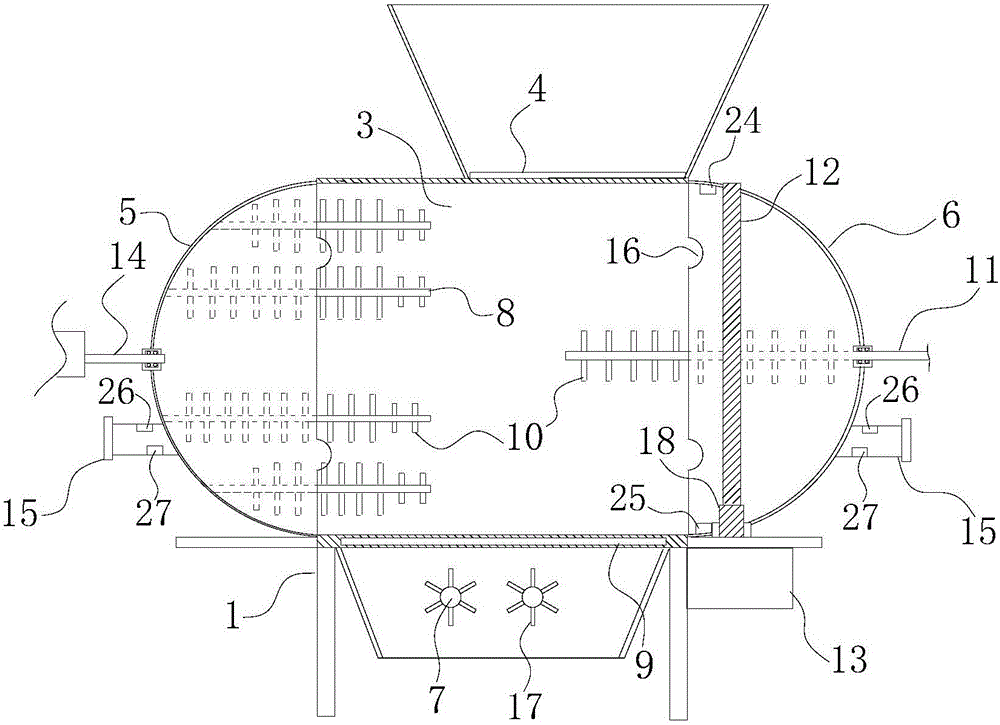

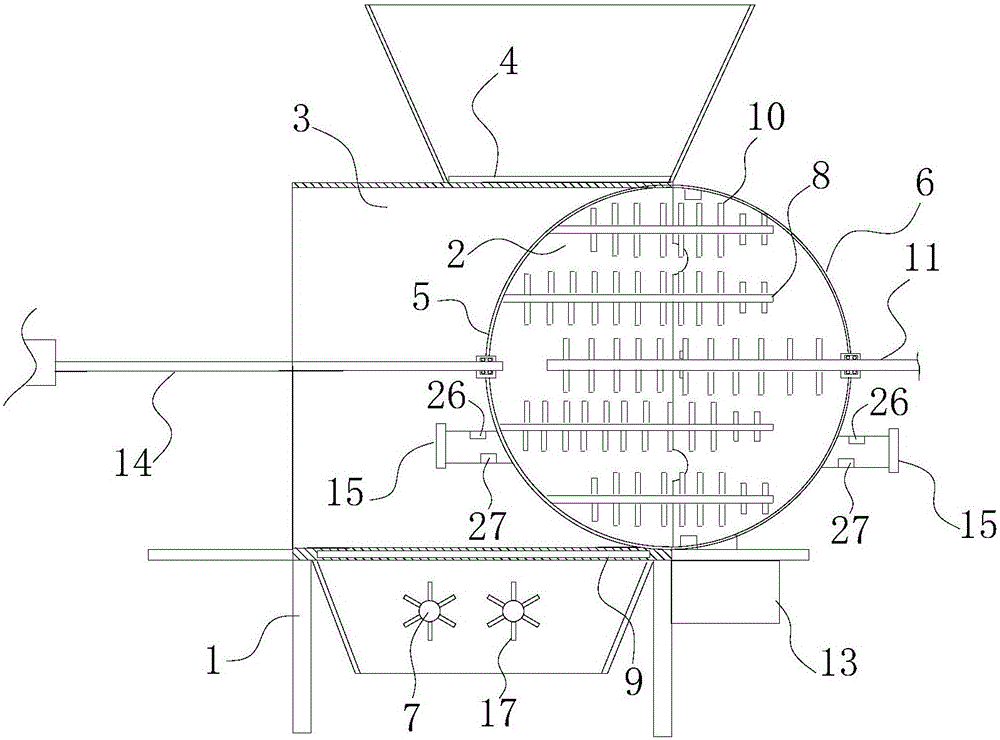

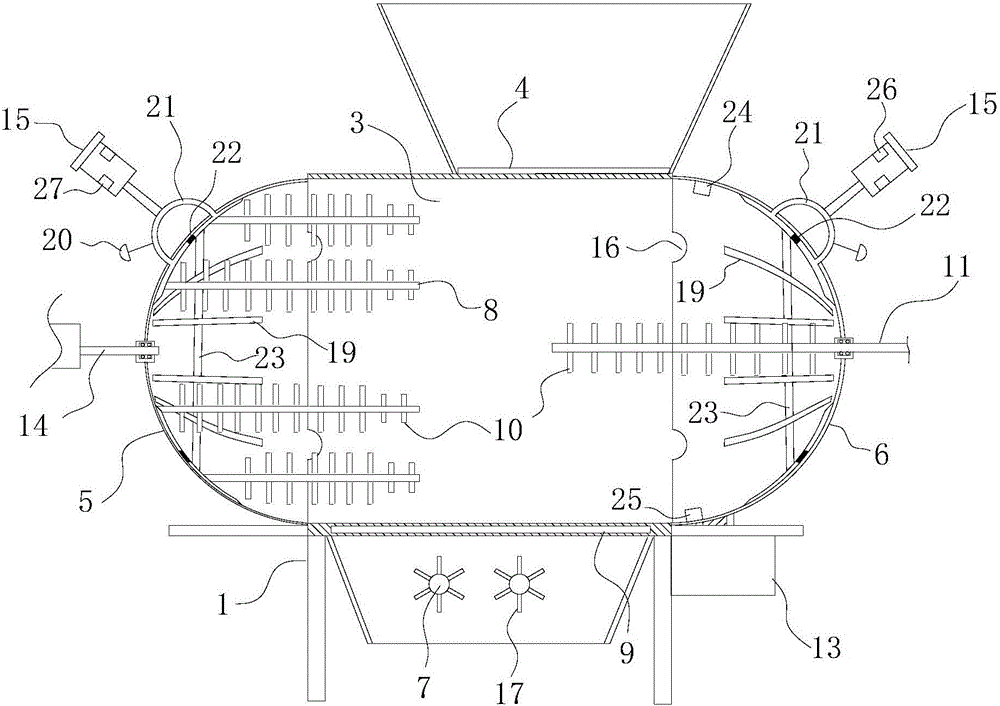

Image

Examples

Embodiment 1

[0038] Choose fresh oolong tea leaves with 2 to 3 leaves in small and medium-sized openings for picking, and set up bamboo mats at a height of 0.5m above the ground according to the daily output, and spread the leaves according to the amount of 0.6kg / m 2 Spread the fresh leaves, and set up a sunshade net with a shading rate of 75% at 2 meters above the bamboo mat. The shading rate can be adjusted according to the intensity of sunlight and the degree of drying of the tea leaves. The tea leaves are lightly stirred every 12 minutes to Ensure that the degree of drying of tea leaves is uniform. Dry until the weight loss rate of the tea leaves is 4%, and the tea leaves are moved into a ventilated room to dry indoors for 40 minutes. Use the green shaker to shake the blue and green and let it stand to dry. The first shake is set at a speed of 10r / min, which lasts 3min, and the green is dried for 1h after shaking; the second shake is set at a speed of 15r / min, which lasts 5min. Dry th...

Embodiment 2

[0043] Choose fresh oolong tea leaves with 2 to 3 small and medium leaves for picking, and set up bamboo mats at a height of 0.8m above the ground according to the daily output, and spread the leaves according to the amount of 0.7kg / m 2 Spread the fresh leaves, set up a sunshade net with a shading rate of 78% 2 meters above the bamboo mat, and lightly turn the tea leaves every 13 minutes to ensure that the tea leaves are evenly dried. Dry until the moisture content of the tea leaves is 5%, and move the tea leaves indoors to dry for 45 minutes. Use the green shaker to shake the blue and green and let it stand to dry. The first shake is set at a speed of 11r / min, which lasts 2min, and after shaking the green is dried for 1.5h; the second shake is set at a speed of 16r / min, which lasts 5min. After airing blue and green 1.5h; The third airing blue and green setting speed 20r / min, lasted 12min, shake green and blue and then air blue and blue 8h, spread leaf thickness 2.5cm when air...

Embodiment 3

[0048] Choose fresh oolong tea leaves with 2 to 3 leaves in small and medium-sized openings for picking, set up bamboo mats at a height of 1m above the ground according to the daily output, and spread the leaves at a rate of 0.8kg / m 2 Spread the fresh leaves, set up a sunshade net with a shading rate of 80% at 2 meters above the bamboo mat, and lightly turn the tea leaves every 15 minutes to ensure that the degree of greening of the tea leaves is uniform. Dry until the water content of the tea leaves is 5%, and move the tea leaves indoors to dry for 50 minutes. Use the green shaker to shake the blue and green and let it stand to dry. The first shake is set at a speed of 10r / min, which lasts 3min, and then aired for 2h after shaking; the second shake is set at a speed of 14r / min, which lasts 6min. Dry blue and green for 2 hours; set the rotation speed of 19r / min for the third time, and last for 9 minutes, shake blue and green leaves for 9 hours, and spread the leaf thickness of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com