Floating body, system for manufacturing polarizing film by using the floating body, and method for manufacturing the polarizing film by using the floating body

A technology of polarizing film and floating body, applied in optics, optical components, polarizing components, etc., can solve the problems of influence and poor polarizing film, and achieve the effect of avoiding oxidation reaction, reducing contact area, and improving the decrease of polarized brightness.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0077] Various embodiments are proposed below for detailed description. The embodiments are only used as examples for illustration and will not limit the scope of protection of the present invention, and the partial repetition of the symbols in the drawings in the embodiments is for the purpose of simplifying the description and does not mean In relation to the different embodiments, the present invention can still be implemented using other features, elements, methods and parameters. The proposals of the embodiments are only used to illustrate the technical characteristics of the present invention, and are not used to limit the patent scope of the present invention. Those skilled in the art will be able to make equal modifications and changes according to the descriptions in the following specification without departing from the spirit of the present invention.

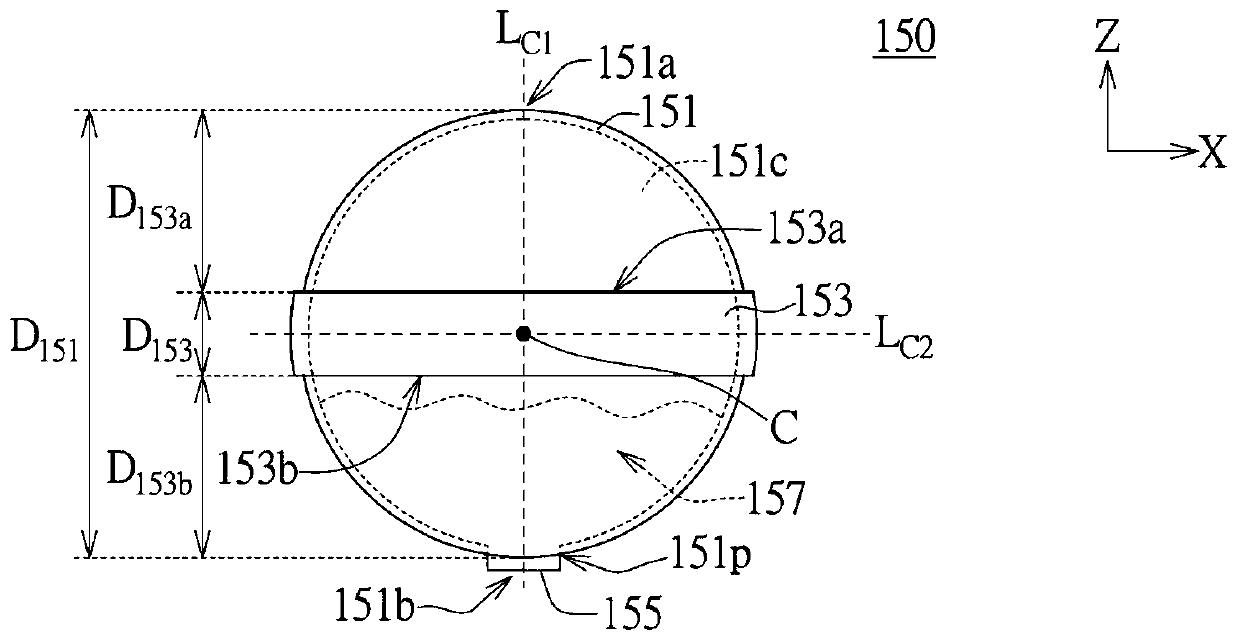

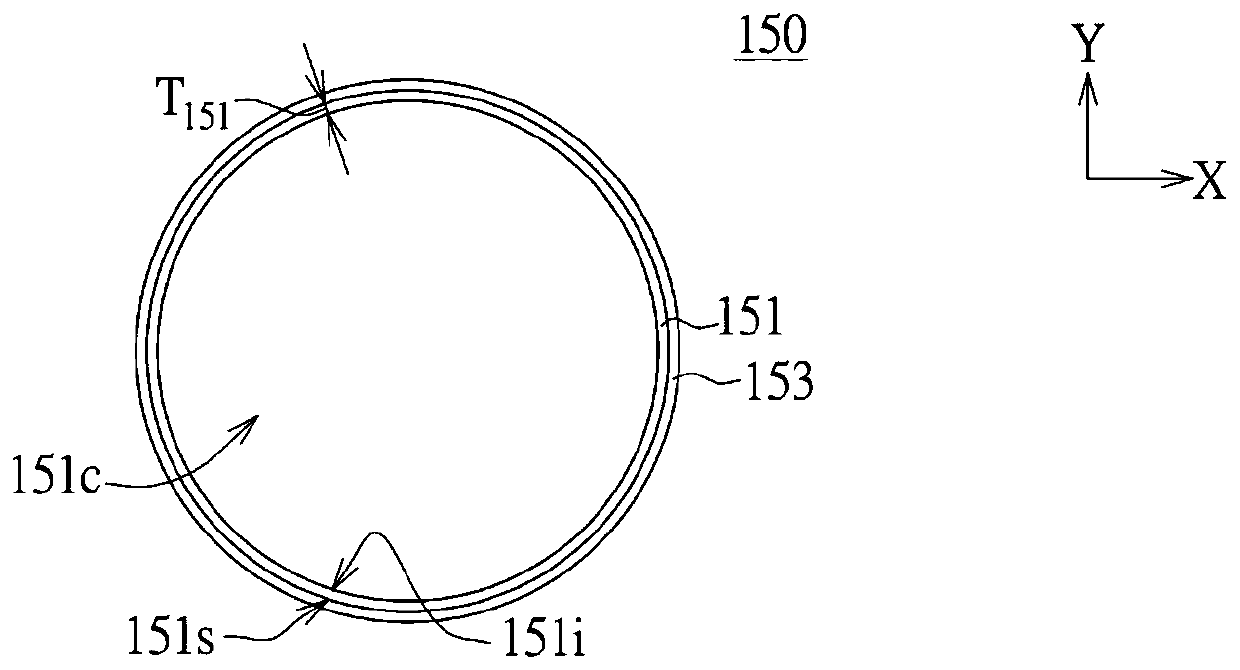

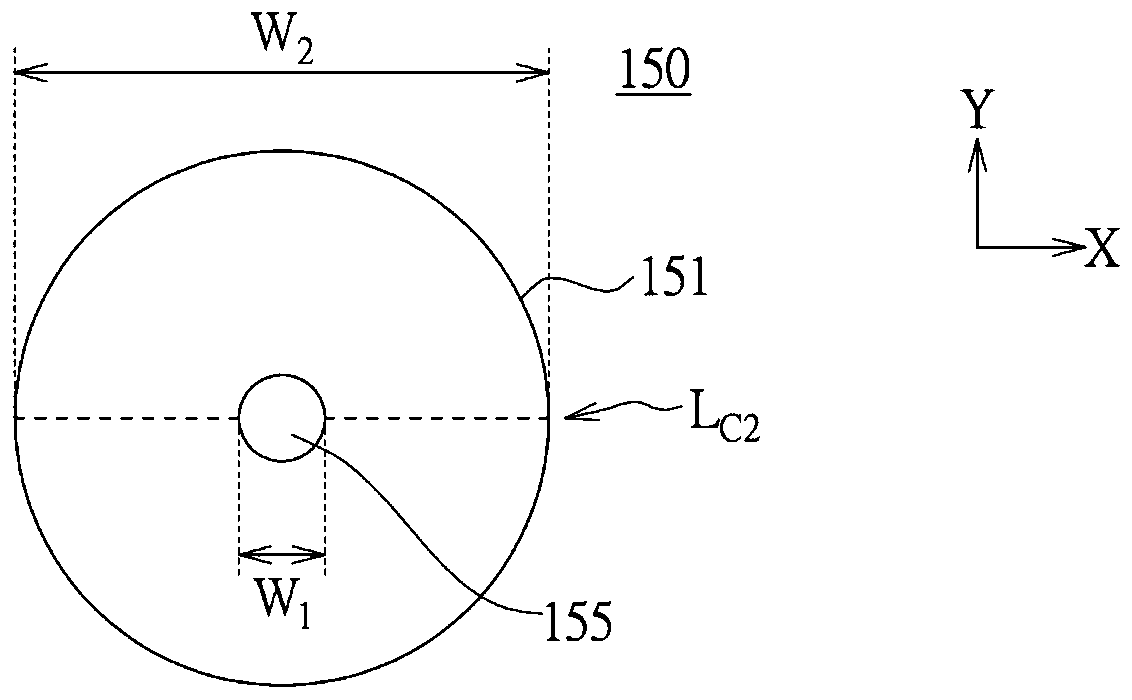

[0078] The invention provides a floating body used in the manufacture of polarizing films. In the preparation pro...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| magnetic force | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com