A kind of mesoporous silica loaded bioglass composite material

A technology of mesoporous silica and composite materials, applied in the field of materials, can solve the problems of rising product cost, unstable bio-glass materials, limiting the practical application of bio-glass, etc., and achieve the effect of simple preparation and stable storage.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

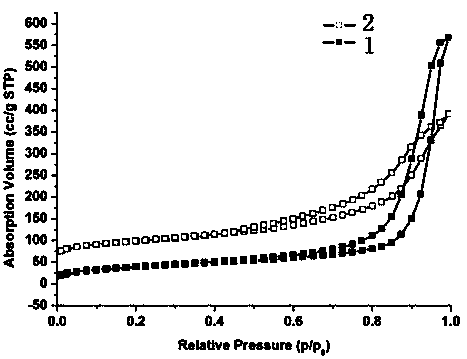

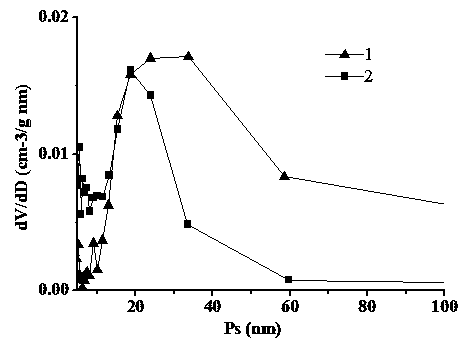

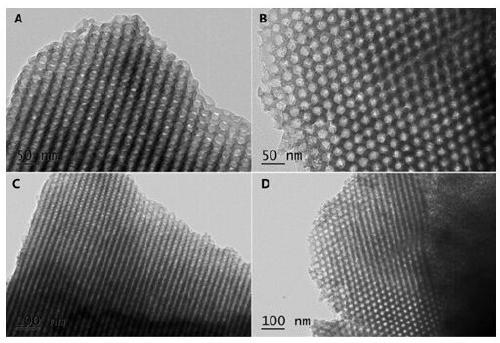

Image

Examples

Embodiment Construction

[0022] The present invention will be described in detail below in conjunction with specific embodiments.

[0023] Preparation Example

[0024] The mesoporous silica-loaded bioglass composite material of the present invention is prepared by the following method:

[0025] 1. Synthesis of mesoporous silica material: First, dissolve 0.50 g Poloxamer F127 and 1.25 g KCl in 30.0 ml HCl solution with a concentration of 2 M, and stir until completely dissolved. After the solution becomes clear, dissolve 0.60 g TMB (mesitylene) was added to the clear solution, and the stirring was continued for 1 h, then 2.23 g tetraethyl orthosilicate (TEOS) was added dropwise to the solution, and the solution was vigorously stirred at 15ºC (600-1000 rpm) 24 h. Then it was transferred to the reactor, hydrothermally reacted at 220 ºC for 24 h, filtered and washed, dried naturally in the air, and finally placed in a muffle furnace for calcination at 550 ºC for 6 h, cooled to room temperature The obta...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com