Preparation method of temperature-resistant PLA (polylactic acid) blister tableware

A tableware and temperature-resistant technology, which is applied in the field of preparation of temperature-resistant PLA plastic blister tableware, can solve the problems of not easy to make heat-resistant PLA products, small market for heat-resistant PLA products, hidden dangers of food safety, etc. The effect of simplified formula composition, high product quality stability and high heat resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0056] (1) Preparation of PLA tableware-like embryos:

[0057] The raw materials of PLA blister tableware are blended and granulated by an extruder to prepare raw material particles of PLA blister tableware. The raw material particles are then extruded through the screw extruder to extrude the melt, pull the sheet, air setting, and roll the sheet to prepare a coil of PLA sheet with a predetermined thickness and width. (The thicknesses of the sheets used to make the blister lids and plates were 0.50 mm and 0.38 mm, respectively).

[0058] The PLA coil is pulled and unrolled, the sheet passes through the preheating table, negative pressure suction molding, and then the product is punched, the product is stacked, the waste is rolled, and the product is put into the box.

[0059] The raw material particles are pulled through the extruder, and then the sheet is prepared by the blister molding process. The PLA blister tableware produced is called blister tableware embryo. Usually ...

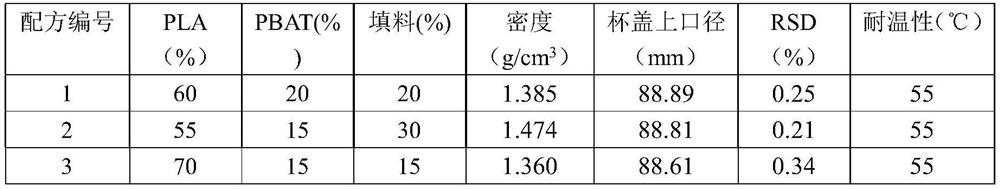

Embodiment 1

[0067] Take the PLA blister cup lid sample embryo with formula composition No. 1-3, place it in a mold container at 45°C, inject 4.5MPa carbon dioxide, soak it at constant temperature and pressure for 20min, quickly release the pressure at a speed of 16MPa / s, open the mold and take out the sample , and cooled at room temperature to obtain a PLA blister cup lid product. The density of the sample, the diameter of the lid and the temperature resistance were tested, and the results are shown in Table 2. After carbon dioxide treatment, the density of the sample has almost no change, and the appearance of the sample has no obvious change. All temperature resistance > 100 ℃.

Embodiment 2

[0069] Take the PLA blister cup lid sample embryo with formula composition No. 1-3, place it in a mold container at 65°C, inject 4.5MPa carbon dioxide, soak it at constant temperature and pressure for 20min, quickly release the pressure at a speed of 16MPa / s, open the mold and take out the sample , and cooled at room temperature to obtain a PLA blister cup lid product. The density of the sample, the diameter of the lid and the temperature resistance were tested, and the results are shown in Table 2. After carbon dioxide treatment, the density of the sample did not change much, and the appearance of the sample did not change significantly. The diameter of the cup lid was 1.40-2.06% smaller than that of the cup lid-like embryo, and the relative standard deviation was 0.16-0.39%. All temperature resistance > 100 ℃.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com