Method of removing arene and olefin in naphtha and solvent oil simultaneously

A technology for petroleum and oil products, which is applied in the field of simultaneous removal of aromatics and olefins in naphtha and solvent oil, which can solve the problems of removal and non-appearance, and achieve the effect of small investment, high removal rate and guaranteed purity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

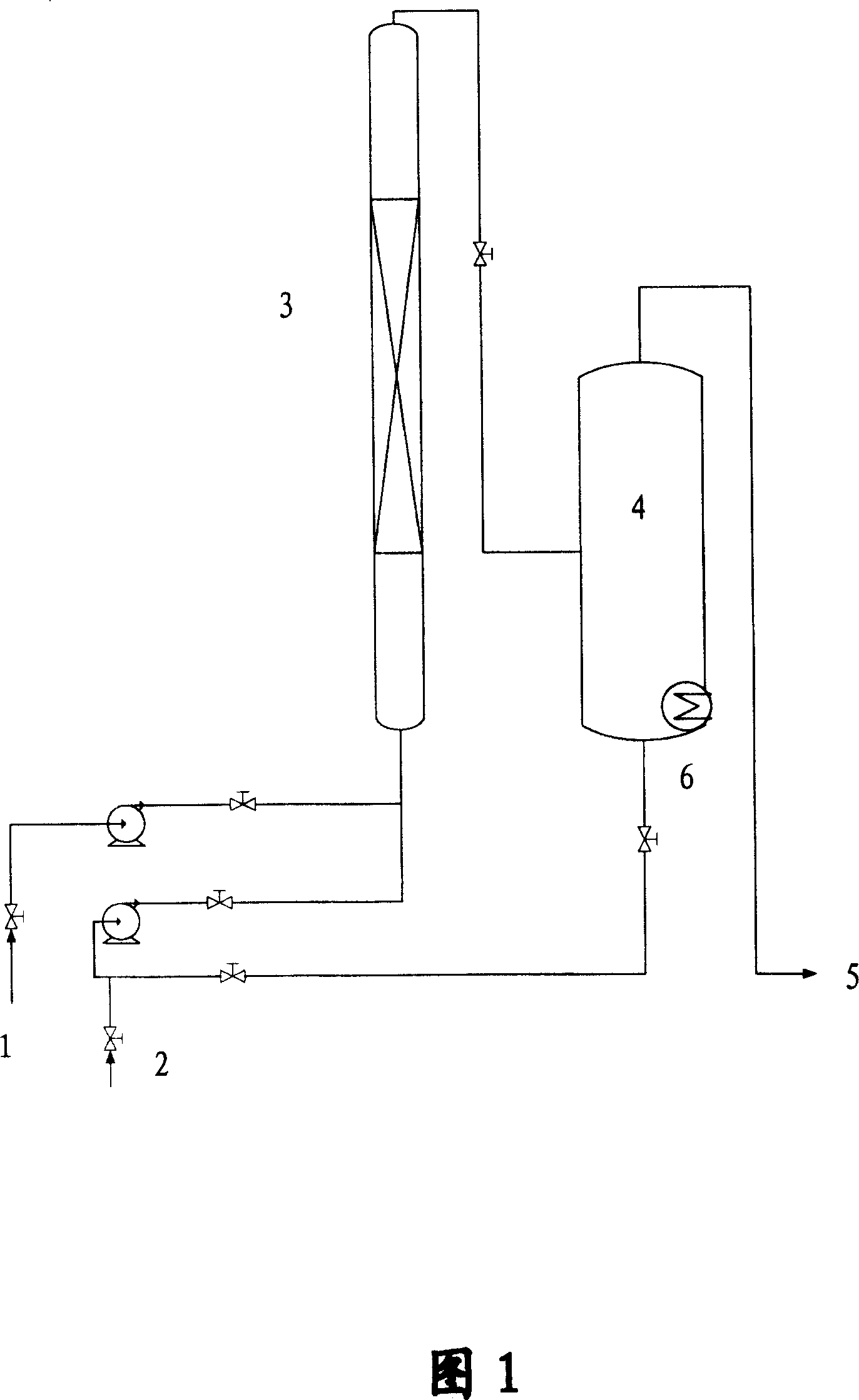

Image

Examples

Embodiment 1

[0029] Embodiment 1: the preparation of ionic liquid

[0030] A metal halide (such as AlCl 3 ) slowly added to the synthesized cationic ligand in a dry nitrogen-protected glove box, stirring during the addition to obtain a liquid state ionic liquid, and then according to different ratios, adding another metal salt, in Stir overnight in the glove box. Finally, make HCl gas at a certain pressure (0.25-0.5 MPa) pass through the above-mentioned ionic liquid for 5-10 minutes to obtain different new ionic liquids.

Embodiment 2

[0032] With the [SO 3 Hbim]Cl-AlCl 3 -ZnCl 2 (The molar ratio of the two metal salts is 5:5) (chloro-butyl-sulfoimidazole-AlCl 3 -ZnCl 2 ) ionic liquid as catalyst (wherein the molar ratio of anion and cation is 2: 1), Daqing cracked naphtha is raw material, wherein the amount of ionic liquid added is 12% of the raw material amount, under the condition of 20 ℃, stirring in a three-necked flask Reaction, the reaction time is 25 minutes, stop stirring, heat to about 90°C, and let it stand for 15 minutes, the reaction product (naphtha) will be automatically layered with the ionic liquid, and the liquid product in the upper layer will be taken out for analysis, and the ionic liquid in the lower layer can be continue to use. The yield of the obtained liquid product is above 99%, the removal rate of olefins is 100%, and the removal rate of aromatics is 28.12%. At the same time, the adsorption and dissolution properties of the ionic liquid are used to make some sulfides adsorb a...

Embodiment 3

[0036] [COOHbim]Cl-AlCl prepared through the HCl gas treatment according to the method of Example 1 3 -ZnCl 2 (The molar ratio of the two metal salts is 5:5) (chlorination-butyl-carboxyimidazole-AlCl 3 -ZnCl 2 ) ionic liquid as a catalyst (wherein the molar ratio of anion and cation is 2:1), Daqing cracked naphtha is a raw material, wherein the amount of ionic liquid added is 5% of the raw material amount, at 20°C and 0.1MPa conditions, in a three-necked flask The reaction was carried out with medium stirring, the reaction time was 25 minutes, the stirring was stopped, heated to about 90°C, and after standing for 15 minutes, the reaction product (naphtha) would be automatically layered with the ionic liquid, and the upper liquid product was taken out for analysis, and the lower layer Ionic liquids can continue to be used. The yield of the obtained liquid product is above 99%, the removal rate of olefins is 88.89%, and the removal rate of aromatics is 78.91%. At the same ti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com