Flame-retardant type refrigerant and preparation method thereof

A refrigerant and flame-retardant technology, which is applied in the field of flame-retardant refrigerant and its preparation, can solve the problems of poor compatibility, uneven dispersion, and poor flame-retardant effect of tetrafluoropropene, and achieve good flame-retardant effect and simplified The effect of preparation process and wide dissolution range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

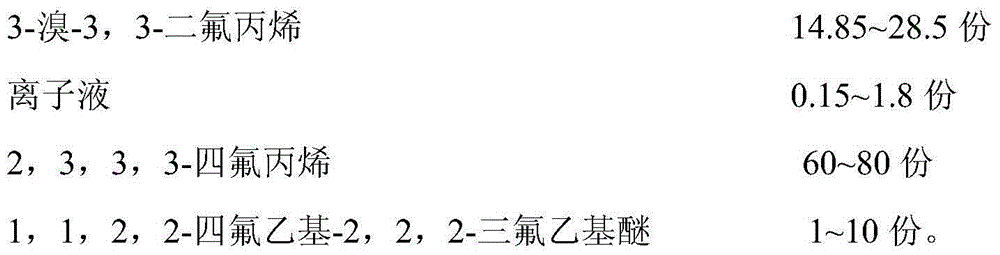

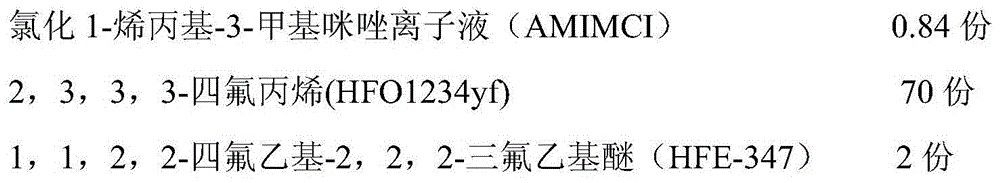

[0028] A kind of flame-retardant refrigerant, according to each 1Kg, the feeding formula is as follows:

[0029]

[0030]

[0031] Its preparation method is as follows:

[0032] Step (1) preparation of ionic liquid flame retardant

[0033] According to the proportion, add 27.16 parts of 3-bromo-3,3-difluoropropene (BFO) and 0.84 parts of 1-allyl-3-methylimidazolium chloride ionic liquid (AMIMCI) into the 200L reactor, in the liquid phase In the state of mixing for 15 hours, the ionic liquid flame retardant was obtained.

[0034] Step (2) mixing

[0035] According to the ratio, the ionic liquid flame retardant prepared in step (1) is mixed with 70 parts of 2,3,3,3-tetrafluoropropene (HFO1234yf), 2 parts of 1,1,2,2-tetrafluoroethyl-2 , 2,2-trifluoroethyl ether (HFE-347, molecular formula CF 3 CH 2 OCF 2 CF 2 H) Add it into a 200L turbulent circulation tank, and mix it in a liquid state for 30 hours with turbulent circulation to obtain the product. The number is WN-...

Embodiment 2

[0037] A kind of flame-retardant refrigerant, according to each 1Kg, the feeding formula is as follows:

[0038]

[0039] Its preparation method is as follows:

[0040] Step (1) preparation of ionic liquid flame retardant

[0041] According to the proportion, add 28.5 parts of 3-bromo-3,3-difluoropropene (BFO) and 1.5 parts of 1-butyl-3-methylimidazolium chloride ionic liquid (BMIMCI) into the 200L reactor, in the liquid state Down mixing for 20 hours to obtain an ionic liquid flame retardant.

[0042] Step (2) mixing

[0043] According to the ratio, the ionic liquid flame retardant prepared in step (1) is mixed with 60 parts of 2,3,3,3-tetrafluoropropene (HFO1234yf), 10 parts of 1,1,2,2-tetrafluoroethyl-2 , 2,2-trifluoroethyl ether (HFE-347, molecular formula CF 3 CH 2 OCF 2 CF 2 H) Add it into a 200L turbulent flow circulation tank, and mix it in a turbulent flow circulation for 40 hours in a liquid state to obtain the product. The number is WN-2.

Embodiment 3

[0045] A kind of flame-retardant refrigerant, according to each 1Kg, the feeding formula is as follows:

[0046]

[0047] Its preparation method is as follows:

[0048] Step (1) preparation of ionic liquid flame retardant

[0049] According to the ratio, add 14.85 parts of 3-bromo-3,3-difluoropropene (BFO) and 0.15 parts of 1-ethyl-3-methylimidazole chloride (EMIMCI) into a 200L reactor, and mix them in the liquid phase 10h, the ionic liquid flame retardant was obtained.

[0050] Step (2) mixing in the turbulent circulation reactor

[0051] According to the ratio, the ionic liquid flame retardant prepared in step (1) is mixed with 80 parts of 2,3,3,3-tetrafluoropropene (HFO1234yf), 1 part of 1,1,2,2-tetrafluoroethyl-2 , 2,2-trifluoroethyl ether (HFE-347, molecular formula CF 3 CH 2 OCF 2 CF 2 H) Adding to a 200L turbulent circulation kettle, and mixing in turbulent circulation for 20 hours in a liquid phase state to obtain the product. The number is WN-3.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com