Molten steel purifier for continuous casting tundish

A technology of continuous casting tundish and purifier, which is applied in the direction of casting molten material container, casting equipment, manufacturing tools, etc. It can solve the problems of incomplete floating and discharge, deterioration of molten steel quality, etc., and achieve maximum specific surface area, quality improvement, quality Improved effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

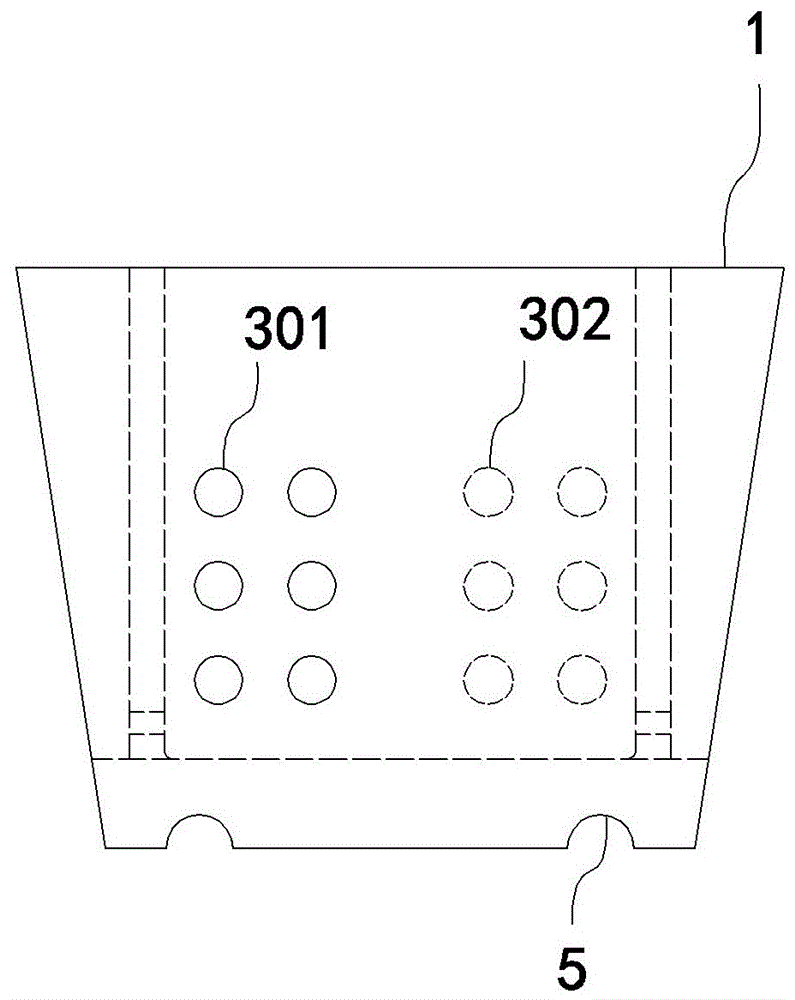

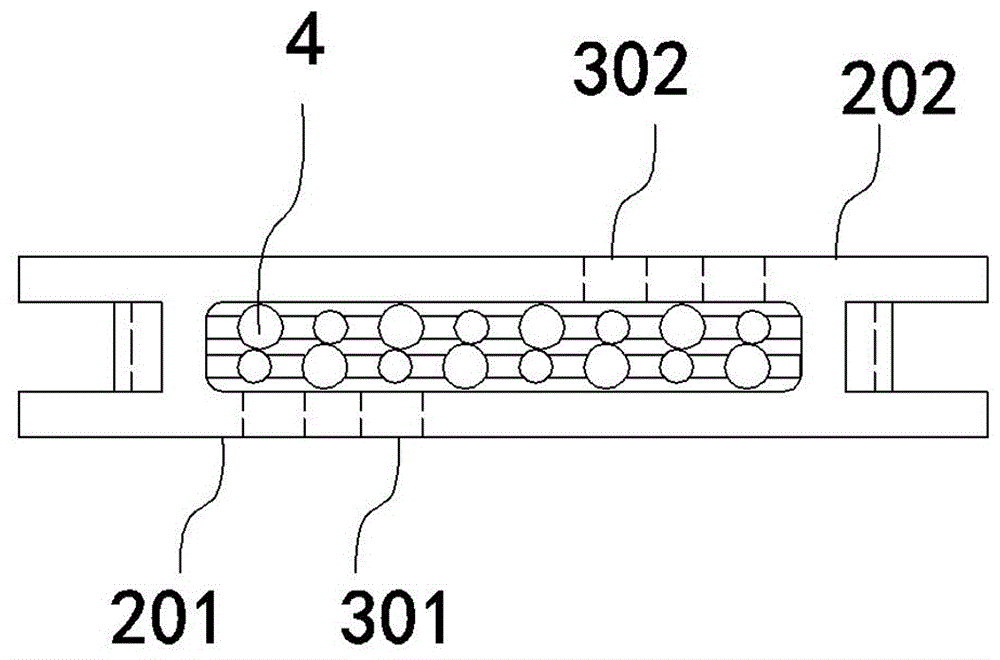

[0019] As shown in the figure, the molten steel purifier for continuous casting tundish includes a refractory box 1; A first hole-shaped steel flow channel 301 and a second hole-shaped steel flow channel 302 are provided respectively; a refractory material purification component 4 is provided in the refractory material box 1 .

[0020] In specific design, the refractory box 1 of the present invention can adopt a trapezoidal structure. see figure 2 As shown, the central axes of the first hole-shaped steel flow channel 301 and the second hole-shaped steel flow channel 302 in the present invention are arranged in a staggered manner. see figure 2 As shown, the refractory purification member 4 of the present invention can adopt a spherical structure. see figure 1 As shown, the first hole-shaped flow steel channel 301 and the second hole-shaped flow steel channel 302 in the present invention are circular flow steel channels. In the present invention, a slagging hole 5 is prov...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com