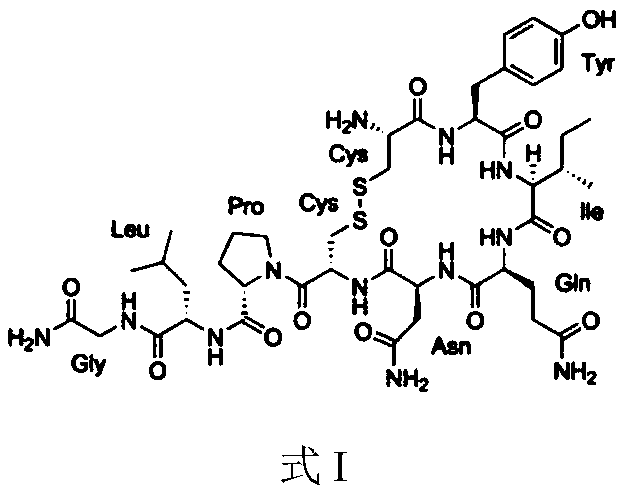

Preparation method of high-purity oxytocin

An oxytocin, high-purity technology, applied in the field of biomedicine, can solve the problems of low yield, low purity, difficult purification, etc., and achieve the effects of low impurity content, high yield and reducing adverse reactions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

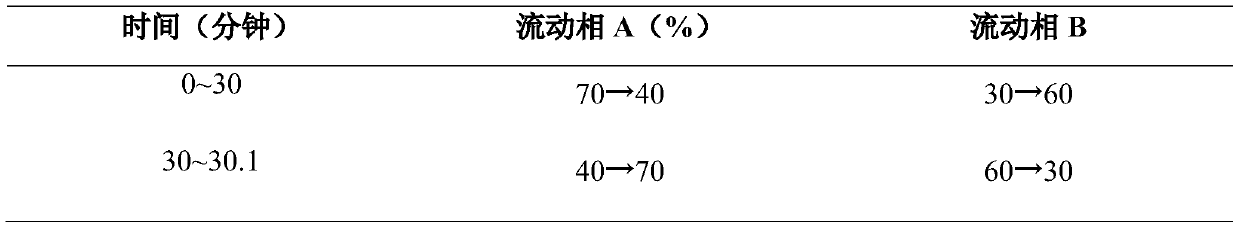

Method used

Image

Examples

Embodiment 1

[0033] (1) Take 100g of crude oxytocin, add 70mL of water, and heat to 45°C to form a homogeneous solution. Add 35 mL of ethanol, slowly cool down to 15°C, let stand for 12 hours, filter, and wash the filter cake with ethanol to obtain the first batch of pure oxytocin.

[0034] (2) Add 20 mL of ethanol to the mother liquor in step (1), lower the temperature to 5° C., let it stand for 12 hours, and filter to obtain the primary pure oxytocin.

[0035] (3) The pure product of oxytocin was dissolved in 30mL of acetone, heated to 40°C, a small amount of solid oxytocin was added as a seed crystal, 5mL of acetone solvent was slowly volatilized, and then the temperature was slowly lowered to 5°C, the solid was precipitated, filtered by suction, and oxytocin was obtained. The second batch of Gongsu pure product.

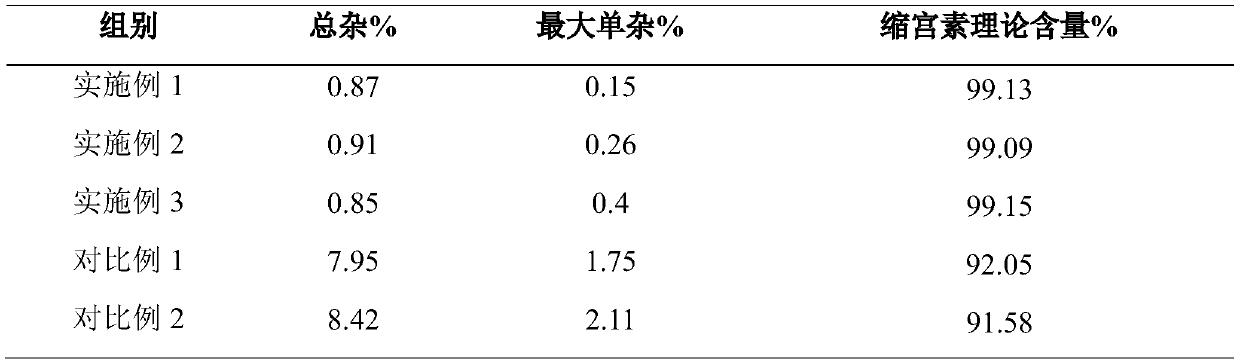

[0036] (4) The first batch and the second batch of pure oxytocin were combined and freeze-dried to obtain 92.6 g of oxytocin raw material, and the content of related substan...

Embodiment 2

[0038] (1) Take 100g of crude oxytocin, add 70mL of water, and heat to 50°C to form a homogeneous solution. Add 40 mL of ethanol, slowly cool down to 20°C, let stand for 12 hours, filter, and wash the filter cake with ethanol to obtain the first batch of pure oxytocin.

[0039] (2) Add 25 mL of ethanol to the mother liquor in step (1), cool down to 0° C., let stand for 12 hours, and filter to obtain the primary pure oxytocin.

[0040] (3) The pure product of oxytocin was dissolved in 30mL of acetone, heated to 40°C, a small amount of solid oxytocin was added as a seed crystal, 6mL of acetone solvent was slowly volatilized, and then the temperature was slowly lowered to 5°C. The second batch of Gongsu pure product.

[0041] (4) The first batch and the second batch of pure oxytocin were combined and freeze-dried to obtain 91.2 g of oxytocin raw material, and the content of related substances was determined.

Embodiment 3

[0043] (1) Take 100g of crude oxytocin, add 70mL of water, and heat to 45°C to form a homogeneous solution. Add 35 mL of ethanol, slowly cool down to 15°C, let stand for 12 hours, filter, and wash the filter cake with ethanol to obtain the first batch of pure oxytocin.

[0044] (2) Add 25 mL of ethanol to the mother liquor in step (1), cool down to 0° C., let stand for 12 hours, and filter to obtain the primary pure oxytocin.

[0045] (3) The pure product of oxytocin was dissolved in 30mL of acetone, heated to 40°C, a small amount of solid oxytocin was added as a seed crystal, 4mL of acetone solvent was slowly volatilized, and then the temperature was slowly lowered to 5°C, the solid was precipitated, filtered by suction, and oxytocin was obtained. The second batch of Gongsu pure product.

[0046] (4) The first batch and the second batch of pure oxytocin were combined and freeze-dried to obtain 89.2 g of oxytocin raw material, and the content of related substances was determi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com