A space high light weight rate aluminum-based reflector and its processing method

A processing method and mirror technology, applied in the field of space optical remote sensing, can solve the problems of difficult processing of mirror blanks, sensitive to changes in mirror surface shape, long processing cycle of mirror bodies, etc., achieving easy preparation and molding, good processing performance, The effect of shortening the processing cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

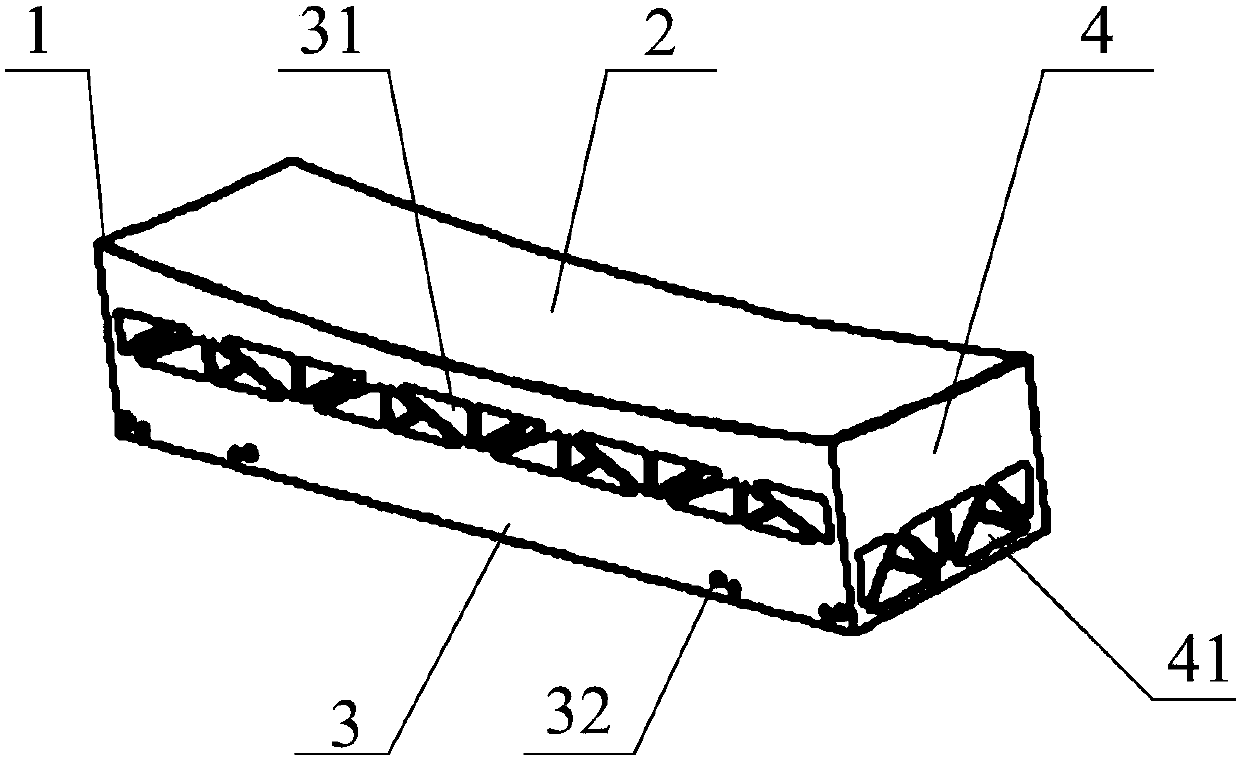

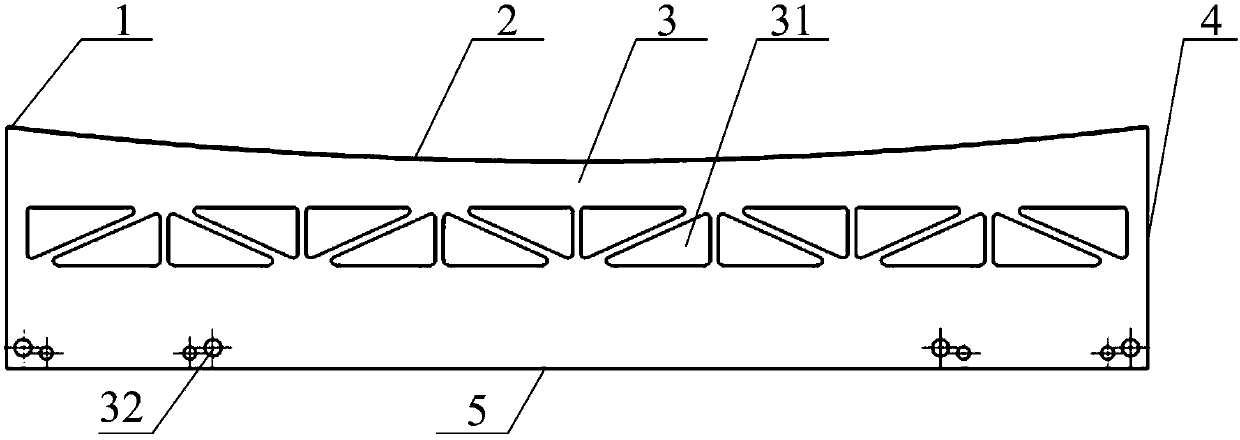

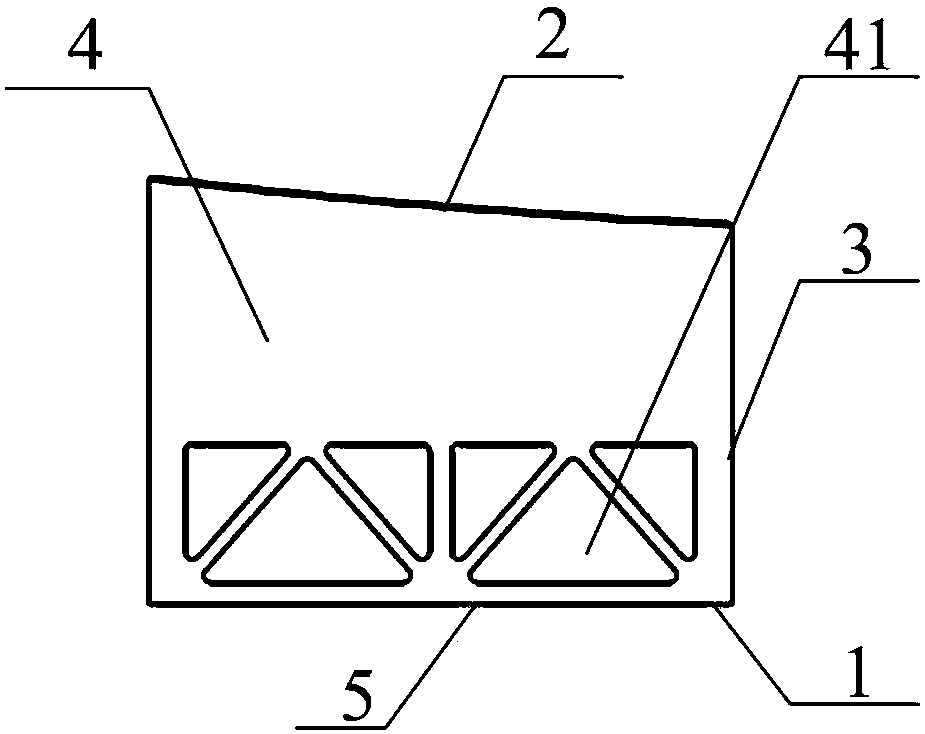

[0030] The present invention will be described in further detail below in conjunction with the accompanying drawings.

[0031] An aluminum-based reflector with a high space and light weight rate of the present invention is used to converge or diverge light to realize light path deflection. The mirror body 1 adopts a lightweight design, the back side 5 of the mirror body 1 is closed, and the side of the mirror body 1 is designed with Lightweight holes improve the structural rigidity and strength of the mirror body 1 . Such as Figure 1 to Figure 3 As shown, the mirror body 1 is mainly composed of six surfaces, namely a mirror surface 2 , two long sides 3 , two short sides 4 , and a back side 5 .

[0032] Such as figure 2 As shown, a plurality of lightweight holes-31 are processed on the two long sides 3 of the mirror body 1. The structures and sizes of the plurality of lightweight holes-31 are all the same, and the plurality of lightweight holes-31 are through holes. That i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com