Full-sealed insulation chain plate conveyor used in high-temperature environment

A technology of chain plate conveyor and high temperature environment, applied in the direction of conveyor, transportation and packaging, can solve the problems of high operation and maintenance cost, high labor cost and high process requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] In order to further explain the technical means and effects of the present invention to achieve the intended purpose of the invention, the following is a full-sealed thermal insulation chain conveyor used in a high-temperature environment according to the present invention in conjunction with the accompanying drawings and preferred embodiments. Its specific implementation, structure, feature and effect thereof are described in detail as follows.

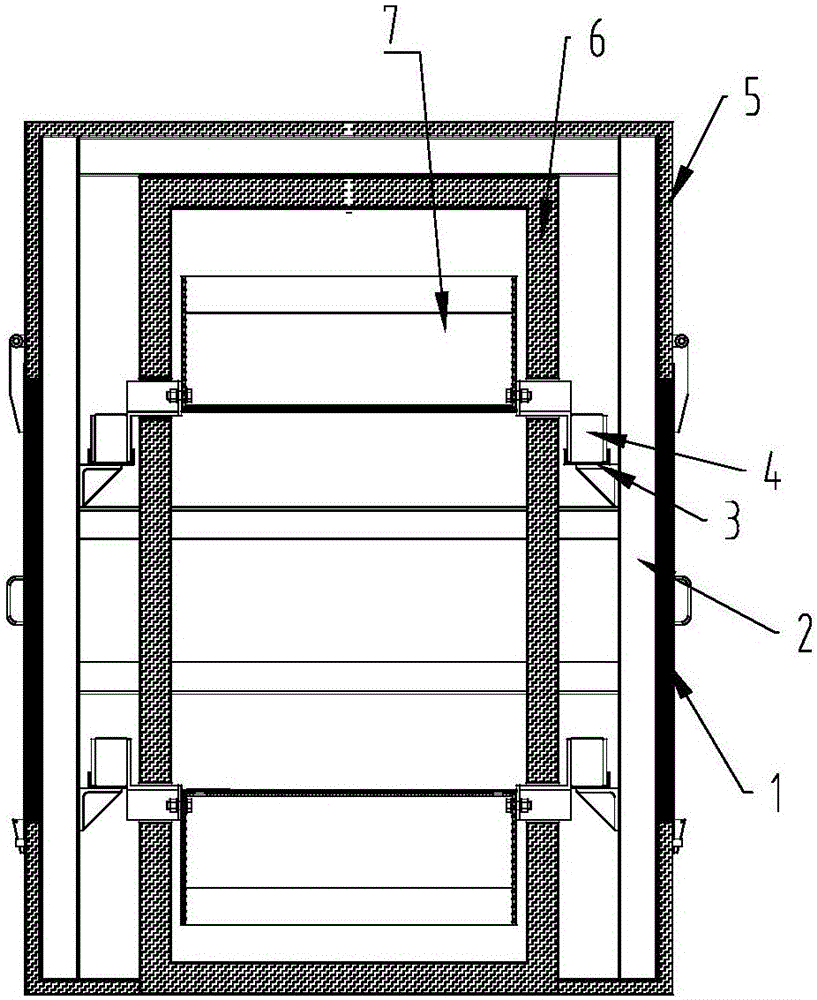

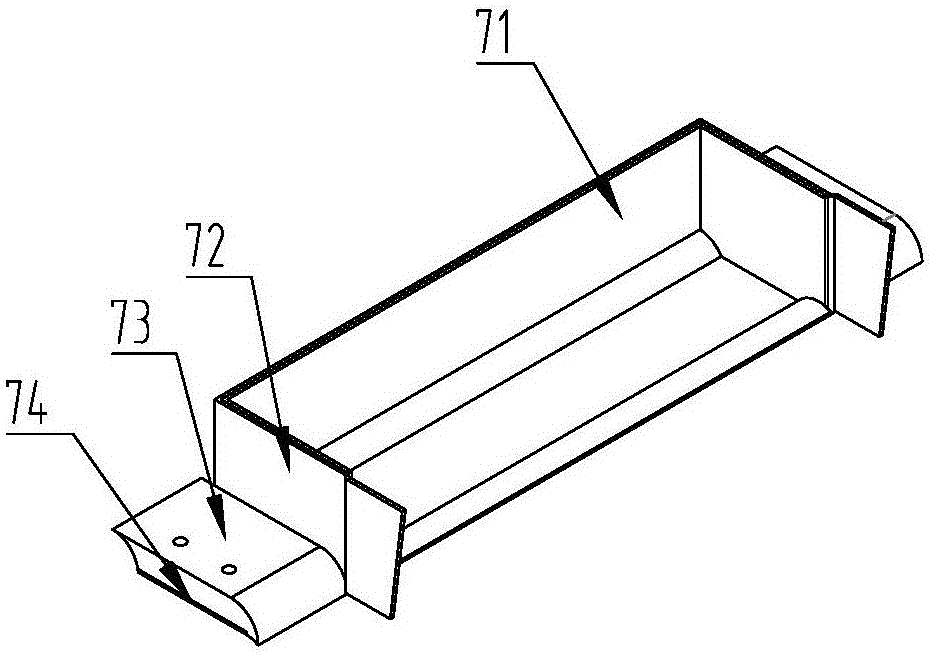

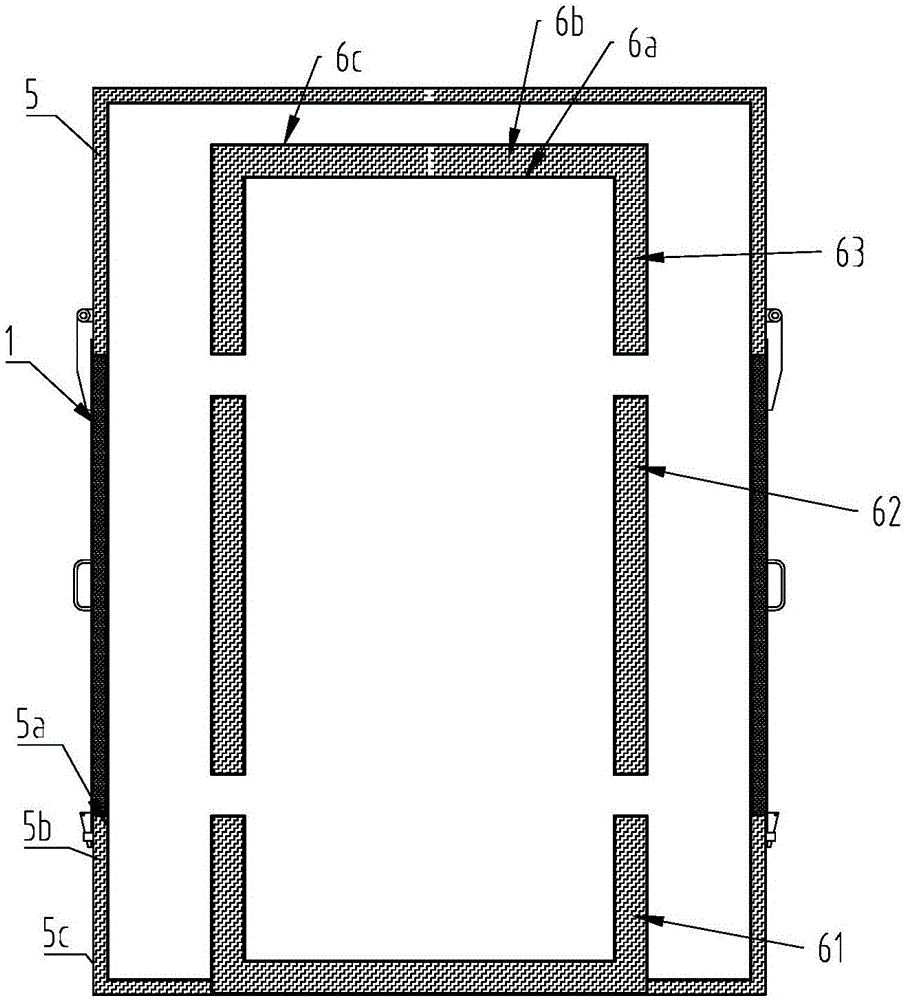

[0036] see Figure 1-4 , Embodiment 1 of the present invention, a fully sealed thermal insulation chain conveyor used in a high temperature environment includes a sealed thermal insulation door 1, a support frame 2, a telescopic track 3, a drive chain 4, an outer thermal insulation shell 5, an inner thermal insulation Housing 6 and conveyor chain plate 7.

[0037] The sealed heat preservation door 1 and the outer heat preservation shell 5 together form a fully airtight outer protective shell, and the airtight heat preservatio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com