Underground coal bunker weighing system

A weighing system and coal bunker technology, applied in the direction of conveyor control devices, conveyor objects, loading/unloading, etc., can solve problems such as waste of manpower, a large amount of manpower, and potential safety hazards, and achieve convenient operation, simple device, and avoid safety hidden effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

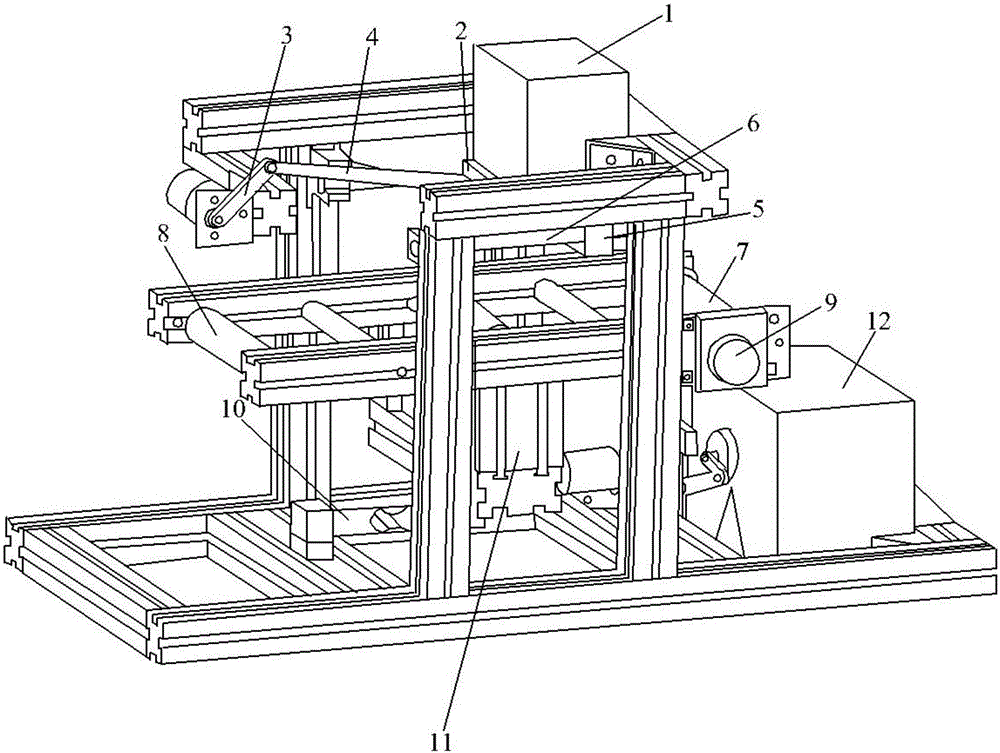

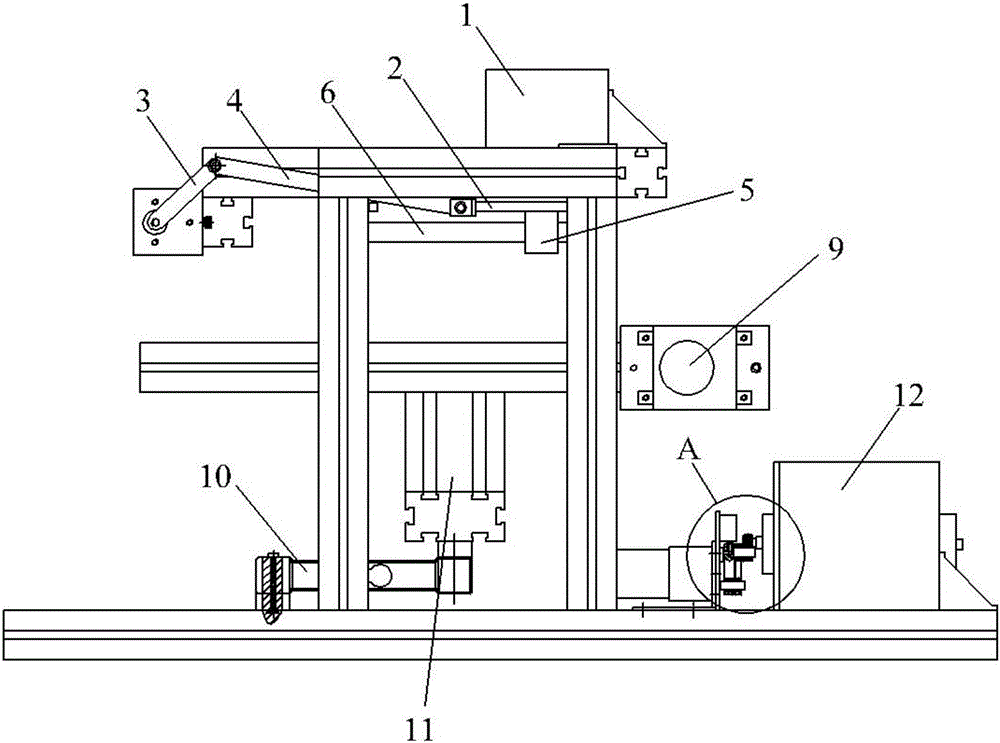

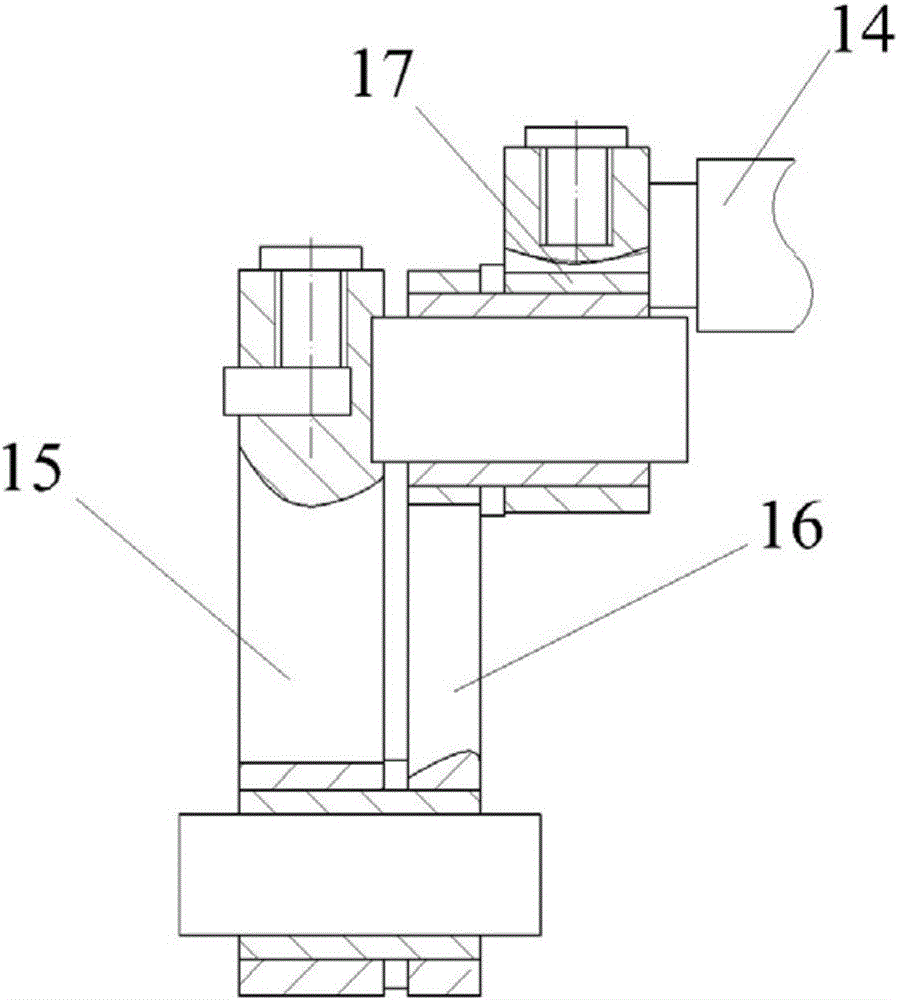

[0034] Such as Figure 1-9 As shown, the underground coal bunker weighing system of the present embodiment includes a frame, a coal inlet hopper, a belt conveyor, a resistance strain gauge sensor, and a coal outlet hopper, as follows:

[0035] The frame is the framework for building the overall structure of the weighing system. It acts as a support, bears the gravity and working load of other parts, and acts as a reference to ensure the relative position between parts. It is stable, reliable, easy to install, cheap and beautiful. Features. The frame is made of industrial aluminum profile, which is an alloy material with aluminum as the main component. Aluminum rods are melted and extruded to obtain aluminum materials with different cross-sectional shapes. The frame includes a base, a column and an upper frame. The base is in a rectangular shape, and is constructed of 2 industrial aluminum profiles in the length direction and 4 industrial aluminum profiles in the width directi...

Embodiment 2

[0075] The difference between this embodiment and Embodiment 1 is that the outer surface of the driving roller of the belt conveyor is wrapped with nylon, which can not only increase the friction between the driving roller and the conveyor belt, but also protect the driving roller from plastic deformation. Other structures Reference can be made to Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com