A kind of anti-wet snow tire tread rubber and preparation method thereof

A technology for tread rubber and snow tires, which is applied in the field of snow tire tread rubber and its preparation, can solve the problem that the wet skid resistance needs to be further improved, and achieves improved wet skid resistance, good viscosity, and improved squeezing. effect of process conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] A kind of anti-wet skid tire tread rubber, comprising the following components in parts by weight:

[0032]

[0033] Wherein, the zinc oxide is nano zinc oxide;

[0034] The sulfur is granular, with a sulfur content ≥ 80wt%;

[0035] The anti-aging agent is N-phenyl-α-aniline and anti-aging agent 4020, and the mass ratio of the two is 1:1.

[0036] The density of the tread rubber of this embodiment is 1.086kg / dm 3 .

[0037] According to the above proportioning, make the following preparation:

[0038] a. master refining

[0039] a1. Take solution polystyrene butadiene rubber, natural rubber, butadiene rubber, zinc oxide, stearic acid, anti-aging agent, protective wax, white carbon black and silane coupling agent and add them to the internal mixer for mixing, mixing for 1-2min ;

[0040] a2. Add carbon black and environmentally friendly aromatic oil, and mix for 2-3 minutes;

[0041] a3. Tablet pressing;

[0042] a4. Cooling with cooling water to obtain film;...

Embodiment 2

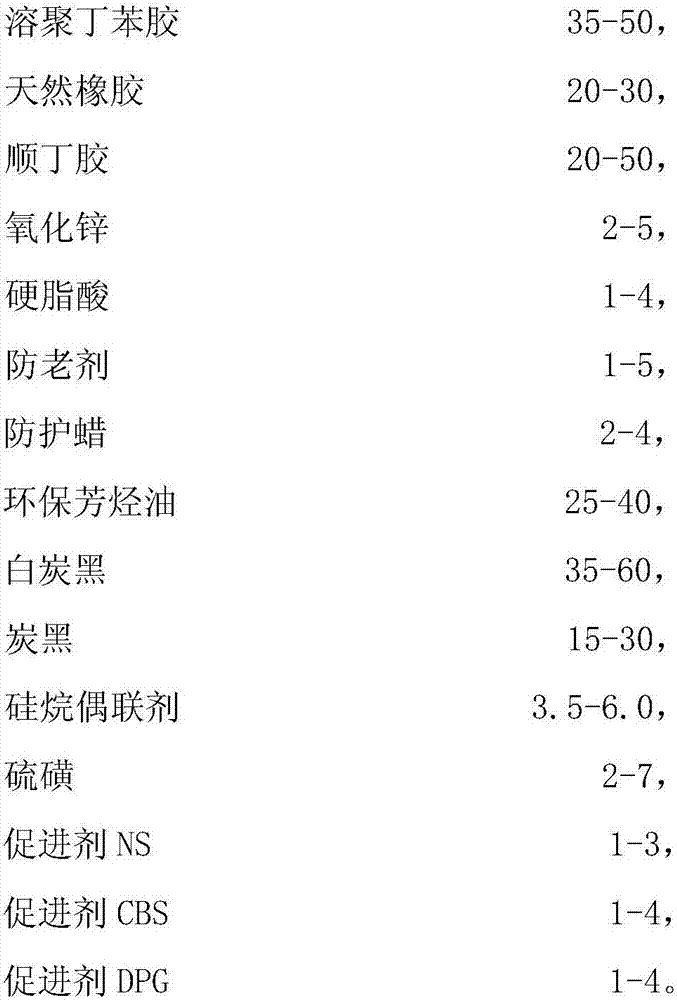

[0048] A kind of anti-wet skid tire tread rubber, comprising the following components in parts by weight:

[0049]

[0050]

[0051] Wherein, the zinc oxide is nano zinc oxide;

[0052] The sulfur is granular, with a sulfur content ≥ 80wt%;

[0053] The anti-aging agent is N-phenyl-α-aniline.

[0054] The density of the tread rubber of the present embodiment is 1.075kg / dm 3 .

[0055] According to the above proportioning, make the following preparation:

[0056] a. master refining

[0057] a1. Take solution polystyrene butadiene rubber, natural rubber, butadiene rubber, zinc oxide, stearic acid, anti-aging agent, protective wax, white carbon black and silane coupling agent and add them to the internal mixer for mixing, mixing for 1-2min ;

[0058] a2. Add carbon black and environmentally friendly aromatic oil, and mix for 2-3 minutes;

[0059] a3. Tablet pressing;

[0060] a4. Cooling with cooling water to obtain film;

[0061] b. Final refinement

[0062] b1. ...

Embodiment 3

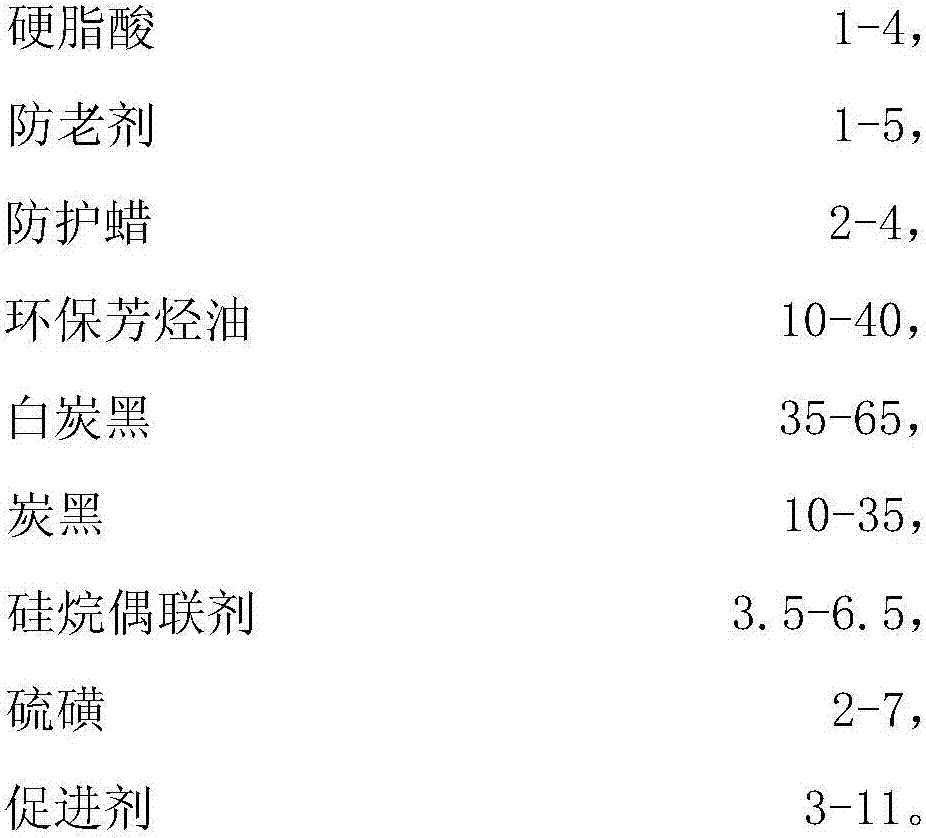

[0066] A kind of anti-wet skid tire tread rubber, comprising the following components in parts by weight:

[0067]

[0068]

[0069] Wherein, the zinc oxide is nano zinc oxide;

[0070] The sulfur is granular, with a sulfur content ≥ 80wt%;

[0071]Described antioxidant is N-phenyl-N'-isopropyl-p-phenylenediamine.

[0072] The density of the tread rubber of the present embodiment is 1.088kg / dm 3 .

[0073] According to the above proportioning, make the following preparation:

[0074] a. master refining

[0075] a1. Take solution polystyrene butadiene rubber, natural rubber, butadiene rubber, zinc oxide, stearic acid, anti-aging agent, protective wax, white carbon black and silane coupling agent and add them to the internal mixer for mixing, mixing for 1-2min ;

[0076] a2. Add carbon black and environmentally friendly aromatic oil, and mix for 2-3 minutes;

[0077] a3. Tablet pressing;

[0078] a4. Cooling with cooling water to obtain film;

[0079] b. Final ref...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap