Double-layer solid wood composite floor and manufacturing method thereof

A technology of solid wood composite flooring and manufacturing methods, which is applied in the direction of manufacturing tools, the joining of wooden veneers, and building construction. The effect of high balance and high stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

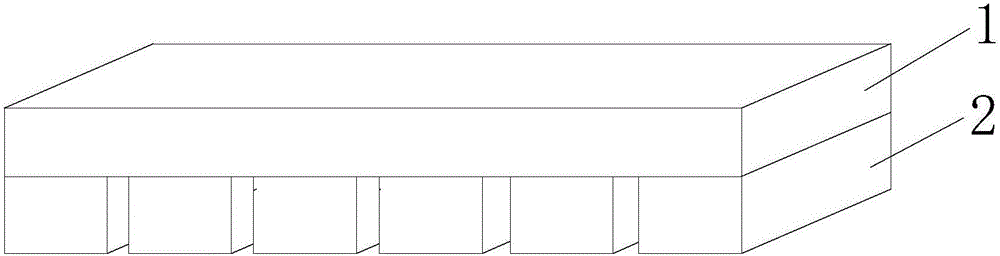

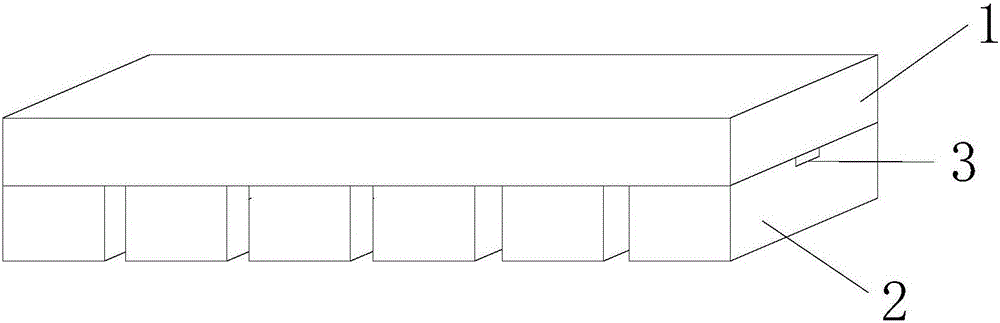

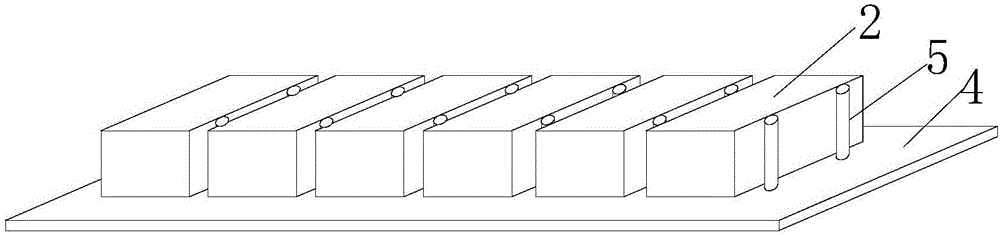

[0026] Embodiment: a kind of double-layer solid wood composite floor, such as figure 1 As shown (not drawn in the figure): including the solid wood surface layer 1 with the wood grain along its own length direction, the bottom of the solid wood surface layer 1 is glued with a plurality of long strips 2 arranged side by side, and the long strips The wood grain of 2 is also along self length direction; The wood grain direction of described elongated small wooden bar 2 and the wood grain direction of solid wood surface layer 1 are perpendicular to each other, and the length of elongated small wooden bar 2 and the width of solid wood surface layer 1 Equal; And there is a gap between the adjacent elongated small wooden strips 2. The gap left between the adjacent elongated wooden strips 2 is 0.5mm-3mm. The thickness of the solid wood surface layer 1 is 3mm-6.5mm, the width is 70mm-260mm, and the length is 500mm-2400mm; the thickness of the elongated wooden strip 2 is 5mm-15mm, and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com