Bucket Mounted Multi-Stage Turbine Interstage Seal and Method of Assembly

An interstage sealing, turbine stage technology, applied in blade support elements, engine elements, machines/engines, etc., to solve problems such as high cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

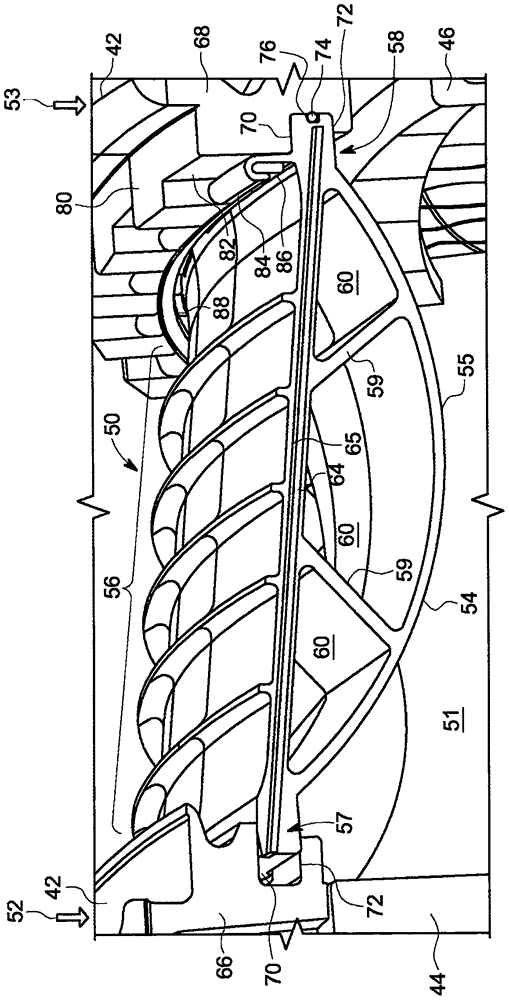

Embodiment Construction

[0171] When introducing elements of various embodiments of the present disclosure, the articles "a," "an," "the," and "said" mean that there are one or more of the elements. The terms "comprising," "including," and "having" are intended to be inclusive and mean that there may be additional elements other than the listed elements. Any examples of operating parameters are not exclusive of other parameters of the disclosed embodiments. Also, as used herein, an "axial" direction is a direction parallel to the central axis, and a "radial" direction is a direction extending from and perpendicular to the central axis. An "outer" position refers to a position in the radial direction that is further from the central axis than an "inner" position.

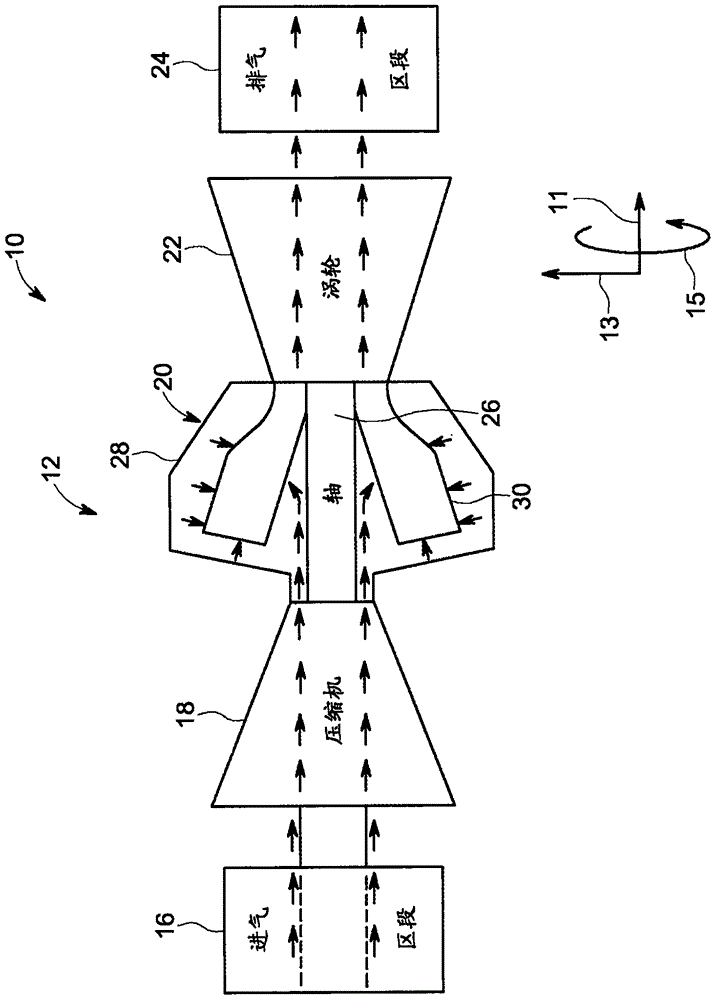

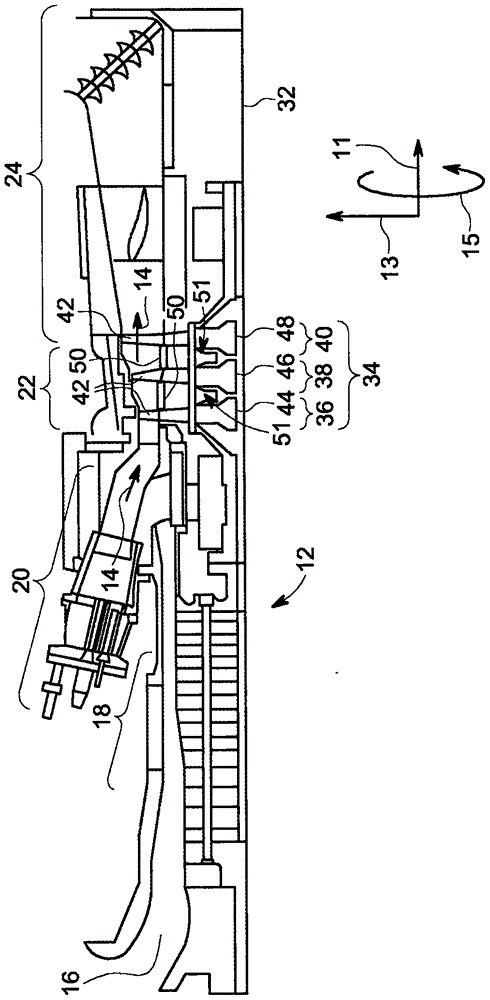

[0172] figure 1 is a block diagram of an exemplary system 10 including a multi-stage turbine engine 12 that may employ the interstage seals described in detail below. In some embodiments, system 10 may include an aircraft, ship, locomotiv...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com