Method and system for reducing engine exhaust emissions

A technology of engine and organic matter, applied in the direction of engine components, combustion engine, engine control, etc., can solve the problems of fuel economy degradation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

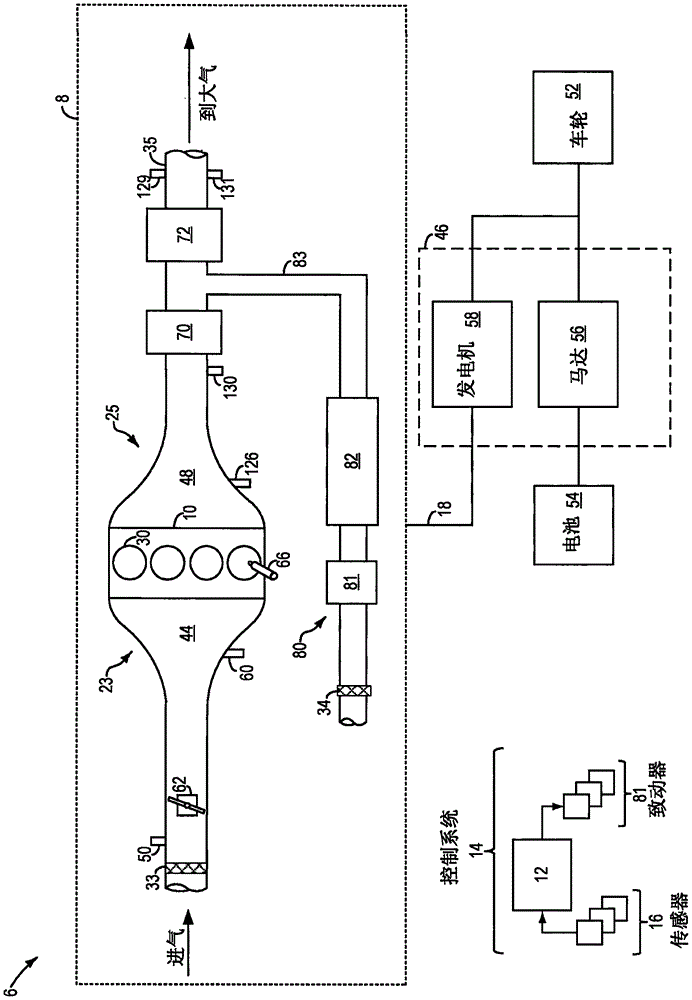

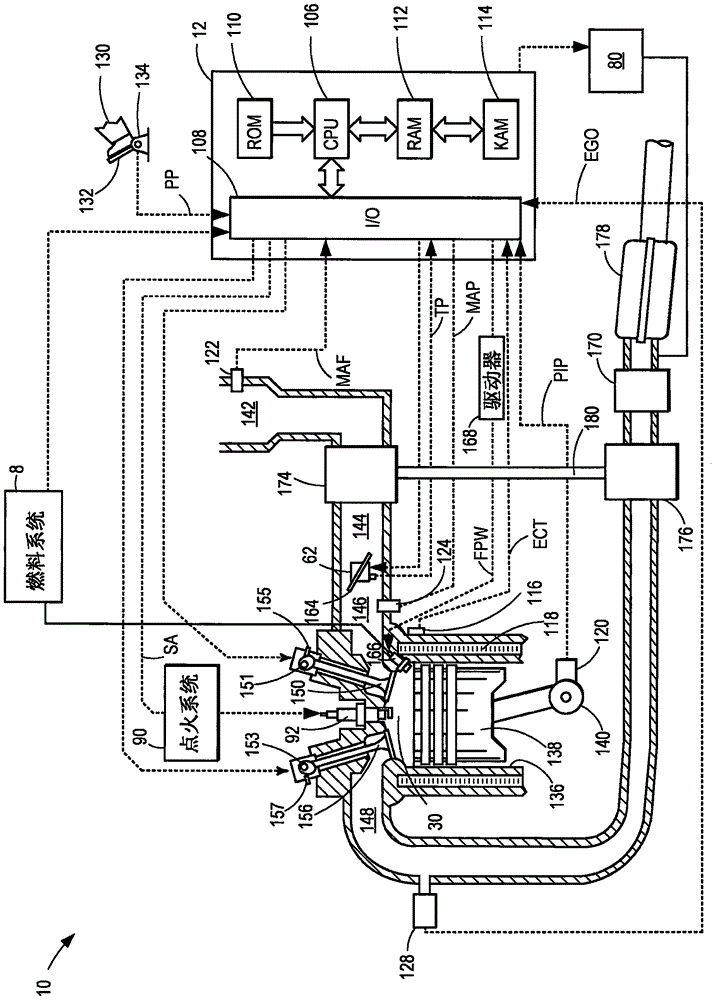

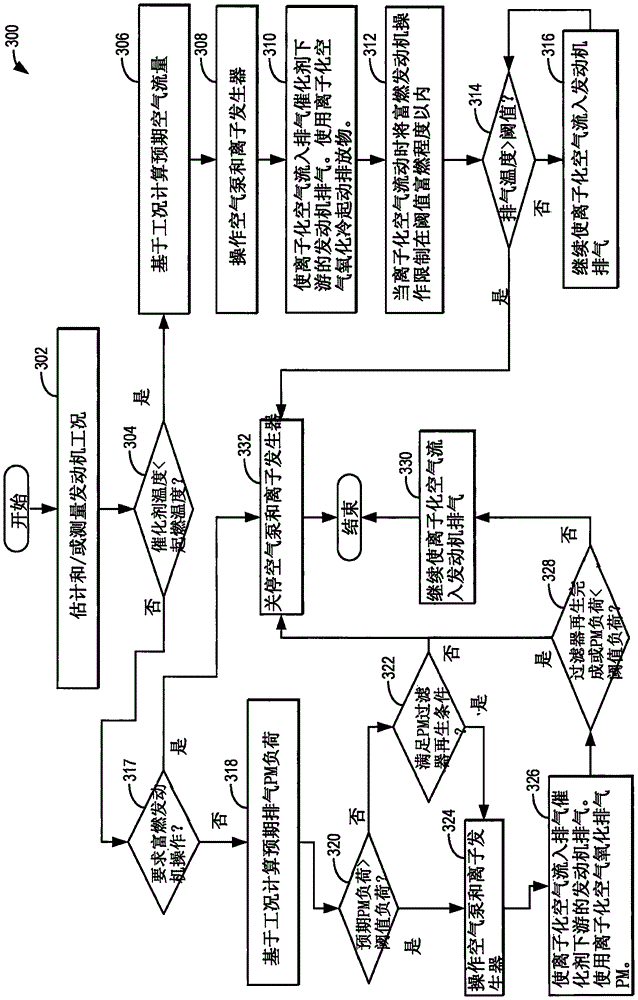

[0015] The present application provides the use of ionized air to treat Figure 1-2 A method and system for cold start emissions and particulate emissions. The engine controller can be configured to execute control programs such as image 3 The example routine in to flow ionized air into engine exhaust downstream of an exhaust oxidation catalyst and upstream of an exhaust particulate filter based at least on catalyst temperature. Cold start emissions that are not oxidized by the oxidation catalyst are oxidized by the ionized air, thereby reducing exhaust emissions. Additionally, ionized air may be used to reduce PM emissions during other conditions when particulate matter (PM) emissions from the engine are high, thereby reducing reliance on exhaust particulate filters. Then, the organic matter oxidized by the ionized air can be exhausted through the exhaust tailpipe. refer to Figure 4 An example cold start operation is shown. In this way, engine exhaust emissions complia...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com