Pot support for cooker

A technology for a pot holder and a cooker, which is applied in the cooker field, can solve the problems of easy failure of adhesive, soiled panels, peeling off of rubber pads, etc., and achieves the effects of avoiding excessive heating and aging, prolonging service life and facilitating assembly.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

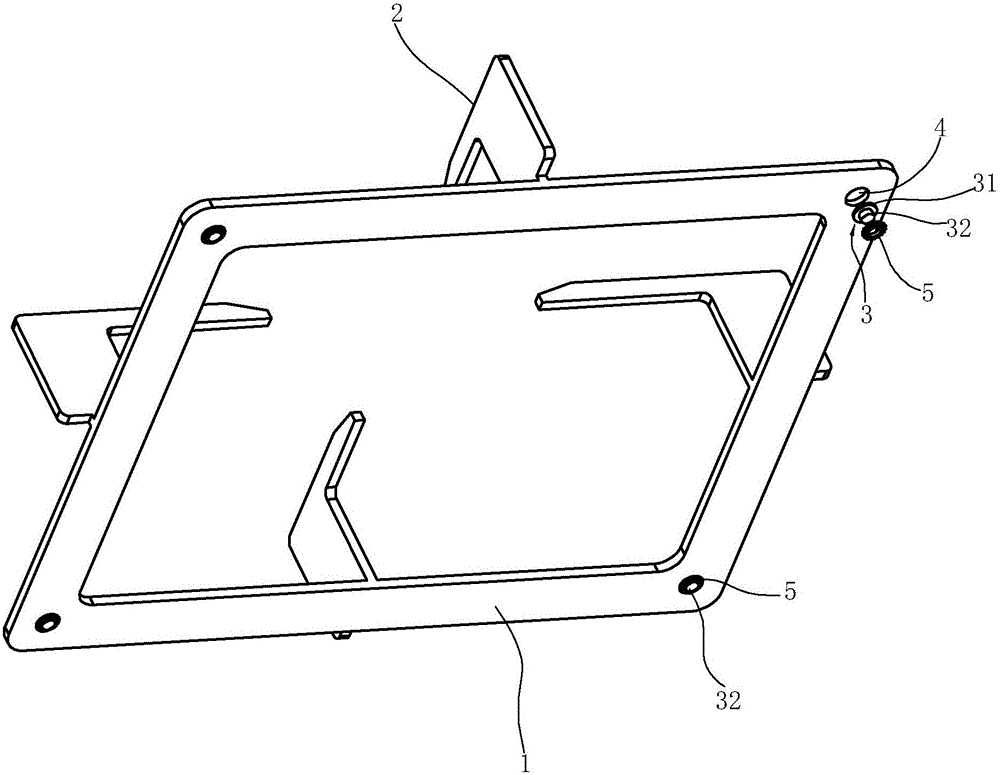

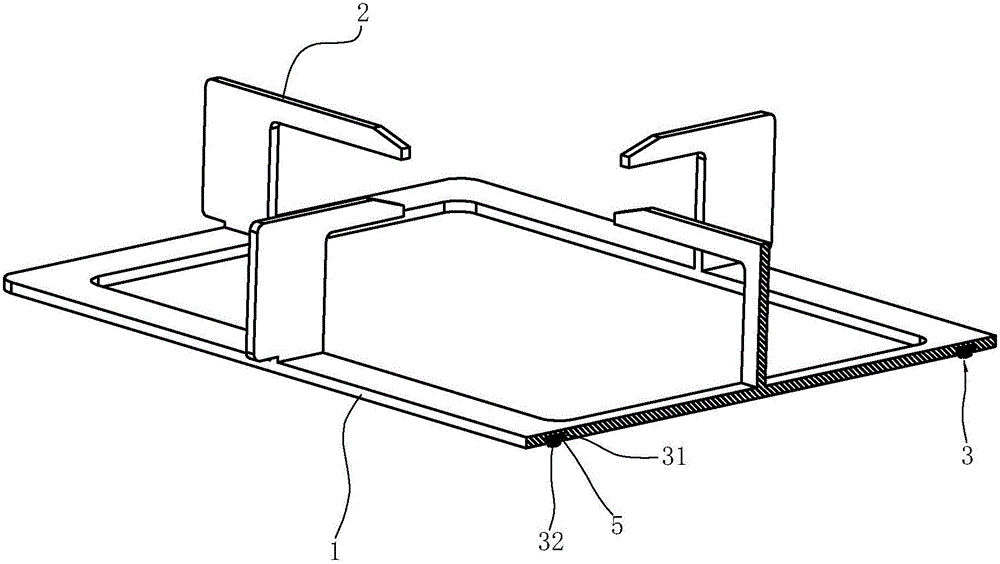

[0034] like Figure 1 to Figure 4 Shown, the cooktop pan support includes:

[0035] The base 1 is the foundation of the entire pot support, and the upper surface of the base 1 is provided with a plurality of legs 2 at intervals; the lower surface of the base is provided with a plurality of blind holes 4 at intervals.

[0036] Feet 3 is a heat-resistant rubber pad, including a support portion 31 and a connection portion 32, the cross section of the support portion 31 is adapted to the cross section of the blind hole 4; the connection portion 32 is connected to the middle part of the support portion 31, and the connection portion 32 The cross-sectional area is smaller than that of the support portion 31 .

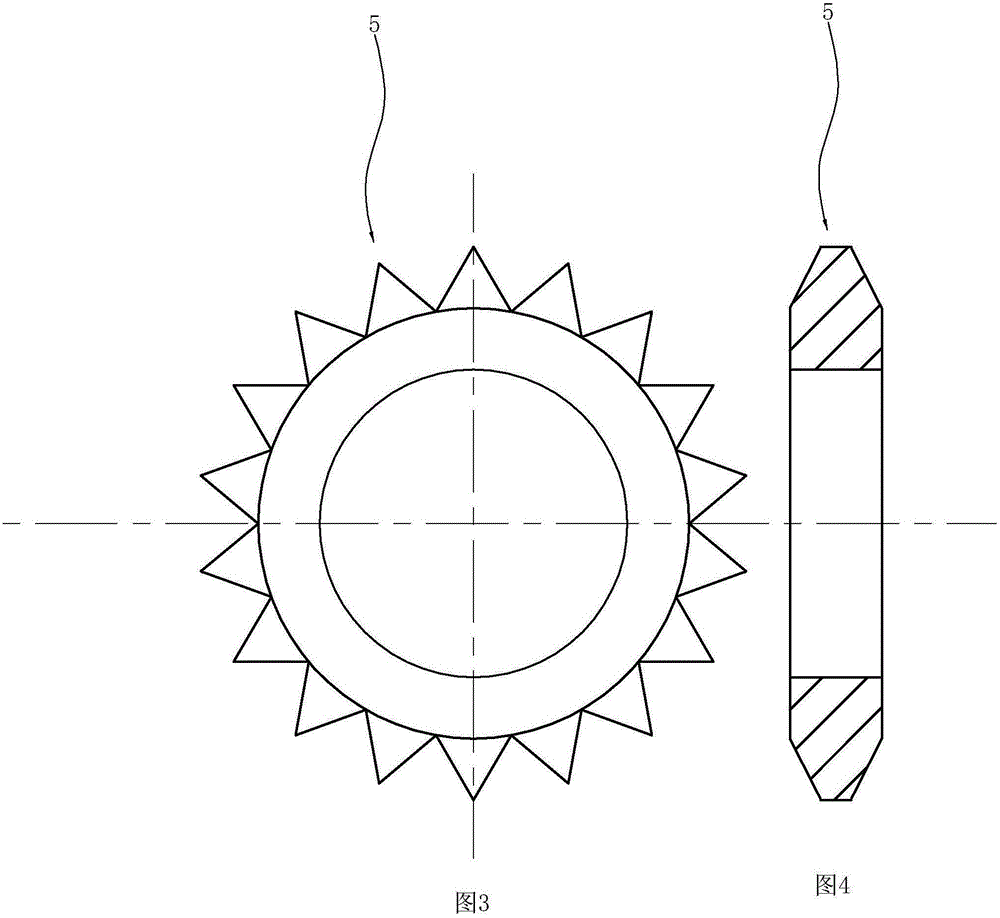

[0037] The positioning part 5 is a ring-shaped structure, and its outer circumference is gear-shaped, which is a metal part that can be deformed under the action of an external force; the cross-section of the through hole in the middle of the positioning part 5 is larger tha...

Embodiment 2

[0040] like Figure 5 to Figure 7 As shown, the pan support for the cooker has a blind hole 4 on the lower surface of the base 1, and a supporting foot (not shown in the figure) on the upper surface.

[0041] The positioning part 5 is a bendable pin structure, made of metal material; one end of the positioning part 5 is welded on the lower surface of the base 1 .

[0042] The footing 3 includes a supporting part 36 and a connecting part 37 connected to each other. The connecting part 37 is inserted in the blind hole 4. The supporting part 36 is exposed to the blind hole 4 and is blocked on the lower surface of the base 1. The supporting part 36 is close to the connecting part. 37 is provided with a transverse shaft hole 34 .

[0043] The other end of the positioning member 5 is passed through the shaft hole 34 so as to lock the pad 3 in the blind hole 4 .

Embodiment 3

[0045] like Figure 8 to Figure 10 As shown, the pan support for the cooker has a blind hole 4 on the lower surface of the base 1, and a supporting foot (not shown in the figure) on the upper surface.

[0046] The positioning piece 5 is arranged in the blind hole 4 and is an interference fit with the blind hole 4 .

[0047] The positioning member 5 is provided with a stepped hole 51 with a large top and a small bottom.

[0048] The pad 3 includes a supporting part 31, a connecting part 32 and a card seat 33; the connecting part 32 is connected between the supporting part 31 and the card seat 33; On the step 54, the connecting part 32 is accommodated in the small hole 53 of the stepped hole 51, and the support part 31 is blocked outside the stepped hole 51 and against the lower surface of the base; the positioning part 5 is arranged in the blind hole 3 and It is an interference fit with the blind hole 3.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com