A flue exhaust flow calibration device and method based on porous probe

A technology of exhaust flow and calibration device, which is applied to the volume/mass flow generated by mechanical effects, and the detection of fluid flow by measuring the pressure difference. It can solve the problems of increased pitot tube measurement error, long measurement time, and chaotic flow direction. The effect of increasing the density of section measuring points, improving measurement accuracy, and improving measurement accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The present invention will be described in detail below with reference to the accompanying drawings and specific embodiments.

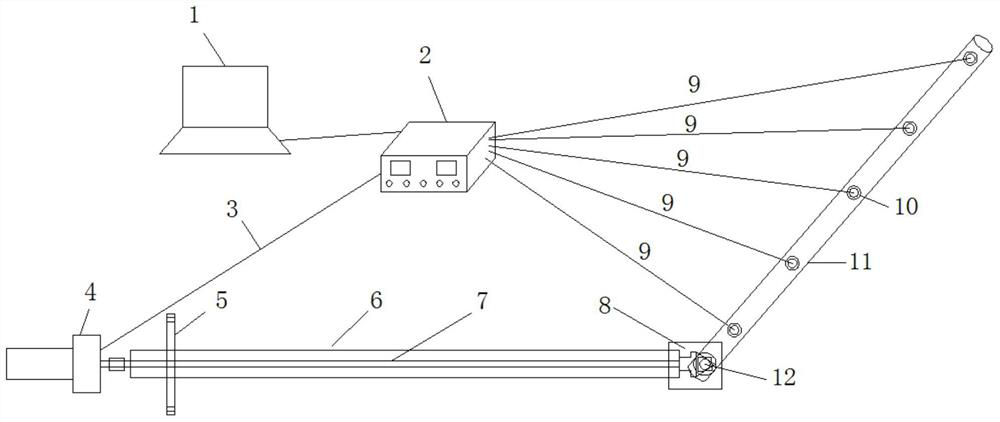

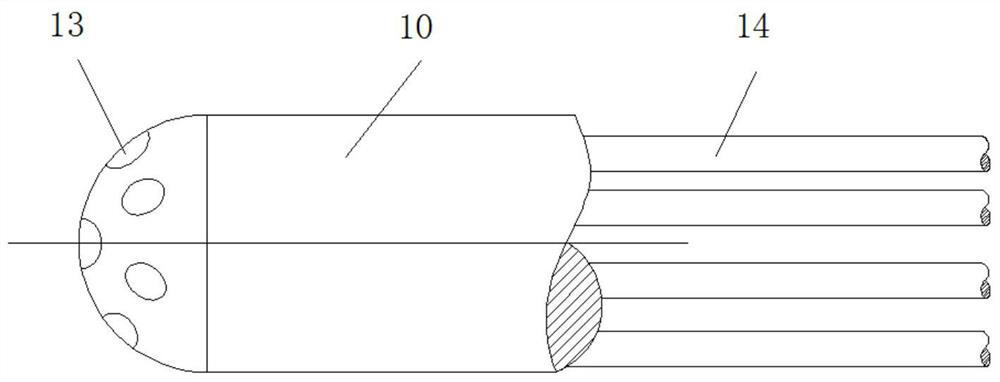

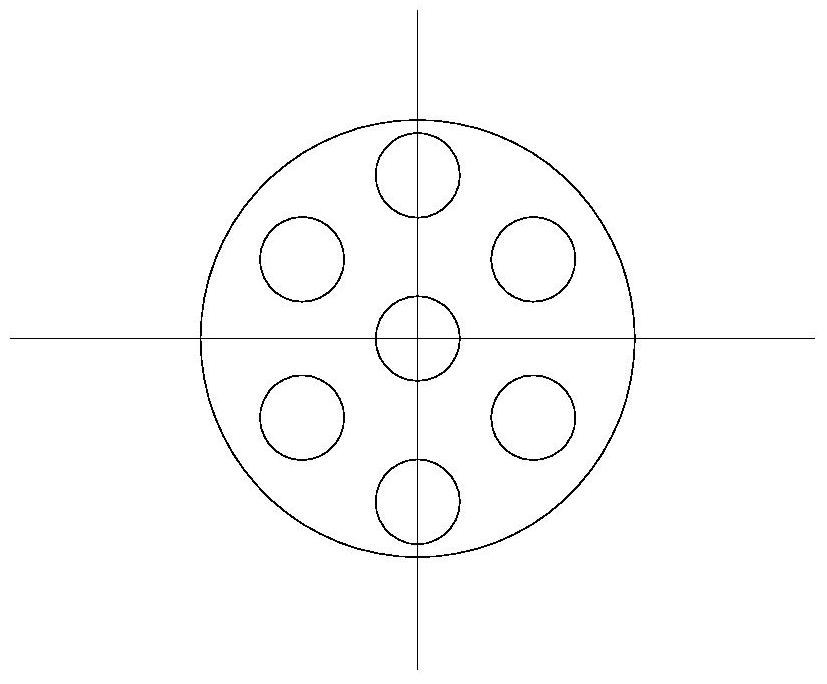

[0032] The structure of the device of the present invention is as follows figure 1 As shown, it is composed of a computer 1, a measurement and control system 2, a stepping motor 4, a fixed flange 5, a length measuring rod 6, a driving rod 7, a worm gear mechanism 8, a rotating rod 11, a rotating shaft 12, and several porous probes 10. Porous probe group and pressure measuring tube 9 etc. are constituted. During on-site calibration, just select a sampling hole in the radial middle of the flue, and extend the length measuring rod 6 and the rotating rod 11 into the flue. The length measuring rod is marked with a scale, and the fixed flange 5 can move back and forth. After the rotating shaft 12 reaches the predetermined position, the fixed flange position is locked and connected with the hole flange 17 by bolts 16 or clamps 15 to fix the calibrati...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com