Experiment device and method utilizing resonance principle to measure Young modulus of metal wire

A technology of Young's modulus and experimental device, applied in teaching models, educational appliances, and analysis of solids using sonic/ultrasonic/infrasonic waves, etc., can solve the problems of wrong data, single principle, and difficult adjustment of telescopes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

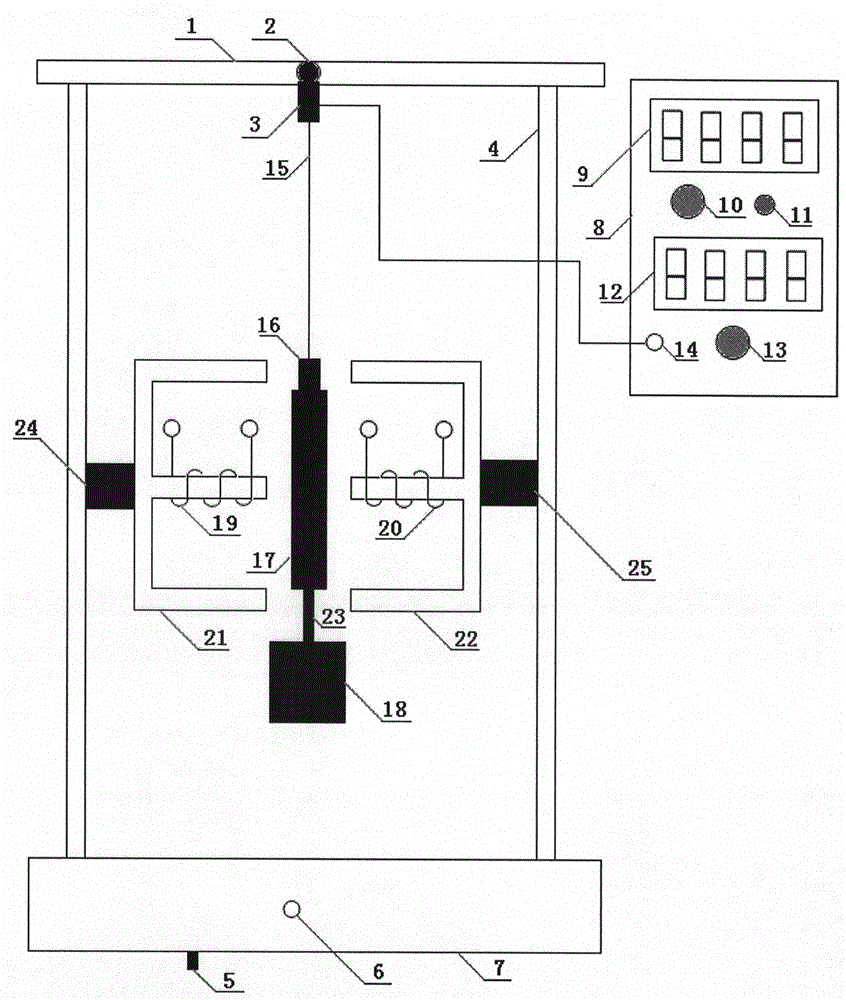

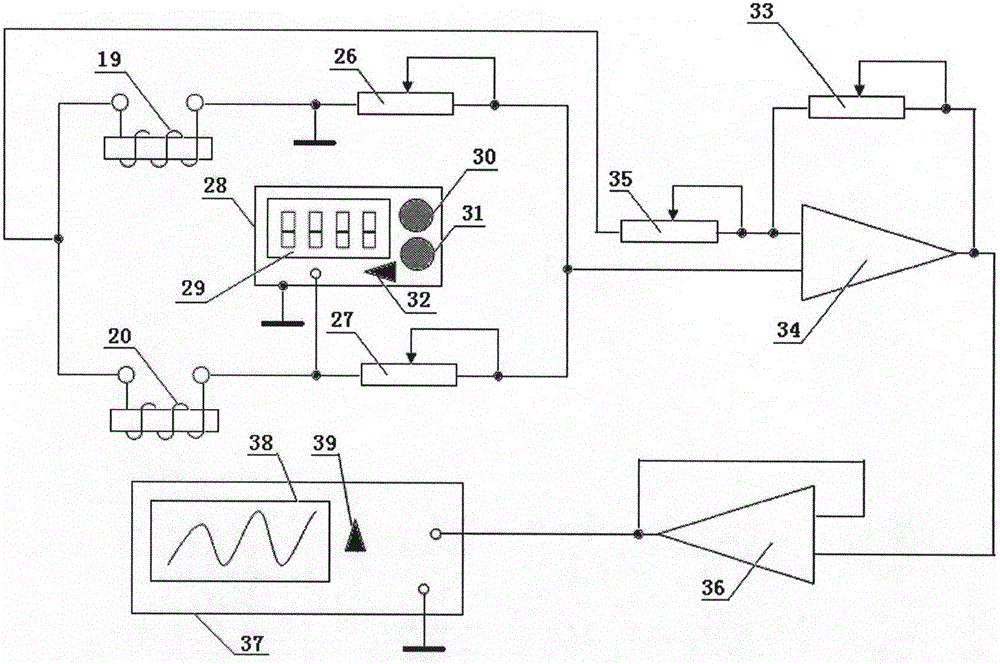

[0039] In the figure, a bracket 4 is set on the bracket base 7, a beam 1 is set on the upper end of the bracket 4, an upper chuck 2 and a vibrator 3 are arranged in the middle of the beam 1, and one end of a metal wire 15 is connected with the upper chuck 2 and the vibration exciter 3, and the other One end is connected with the lower chuck 16, and the lower chuck 16 is fixed with a movable armature 17, and the movable armature 17 is connected with an iron block 18 through a connecting device 23. The exciter 3 is connected to the sinusoidal signal source 8 through the interface 14 between the exciter and the sinusoidal signal source, and the sinusoidal signal voltage amplitude output by the sinusoidal signal source 8 can be continuously adjusted by the sinusoidal signal voltage amplitude adjustment knob 13, and can be adjusted at The sinusoidal signal voltage amplitude is displayed on the display screen 12; the sinusoidal signal frequency can be continuously adjusted through th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com