Method for rotation speed extraction through peeling off fault corresponding impact by employing rolling ball track

A rolling bearing and feature extraction technology, which is applied in the field of fault diagnosis technology and signal processing and analysis, can solve the problems of difficulty in installing the tachometer, inability to directly obtain the speed signal, and inconvenient hardware installation, so as to avoid installation restrictions and save the cost of speed extraction Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

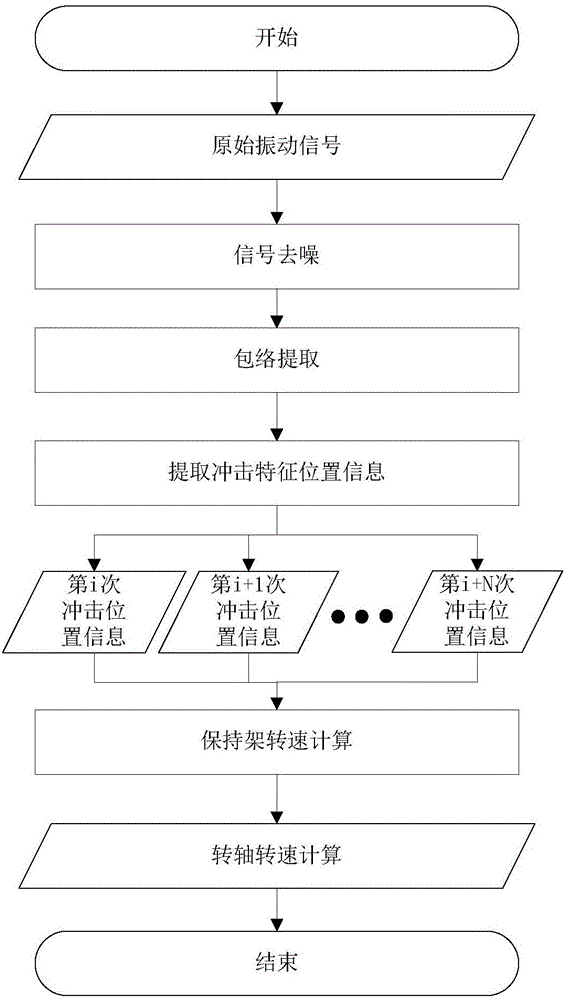

[0027] Embodiment 1: as Figure 1-4 As shown, a method for extracting the rotational speed through the corresponding impact characteristics of the spalling fault of the rolling bearing raceway, the specific steps of the method are as follows:

[0028] Step1. Use the charge amplifier to amplify the original vibration signal of the faulty rolling bearing collected by the acceleration sensor;

[0029] Step2. Perform AR pre-whitening processing on the amplified original vibration signal, and then use the MED filter method combined with spectral kurtosis to enhance the fault impact characteristics in the pre-whitening signal to obtain vibration signals with obvious fault impact characteristics;

[0030] Step3, carry out Hillbert transformation to the signal obtained in step Step2, construct envelope signal;

[0031] Step4, extracting the impact feature position information in the envelope signal greater than the threshold;

[0032] Step5. First determine the number of impact feat...

Embodiment 2

[0040] Embodiment 2: as Figure 1-4 As shown, a method for extracting the rotational speed through the corresponding impact characteristics of the spalling fault of the rolling bearing raceway, the specific steps of the method are as follows:

[0041] Step1. Use the charge amplifier to amplify the original vibration signal of the faulty rolling bearing collected by the acceleration sensor;

[0042] Step2. Perform AR pre-whitening processing on the amplified original vibration signal, and then use the MED filter method combined with spectral kurtosis to enhance the fault impact characteristics in the pre-whitening signal to obtain vibration signals with obvious fault impact characteristics;

[0043] Step3, carry out Hillbert transformation to the signal obtained in step Step2, construct envelope signal;

[0044] Step4, extracting the impact feature position information in the envelope signal greater than the threshold;

[0045] Step5. First determine the number of impact feat...

Embodiment 3

[0051] Embodiment 3: as Figure 1-4 As shown, a method for extracting the rotational speed through the corresponding impact characteristics of the spalling fault of the rolling bearing raceway, the specific steps of the method are as follows:

[0052] The specific parameters are as follows: 1) Type 6205 rolling ball bearing is selected, the pitch diameter is 38.5mm, the rolling element diameter is 7.938mm, the number of rolling elements is 9, and the contact angle is 0°; 2) The fault type is peeling fault of the outer ring; 3) Use NI USB9215 data acquisition card and DH-5853 charge amplifier for high-frequency sampling, and set the rotational speed at 9.77 Hz; 4) The sensor selected in the acquisition example is a piezoelectric acceleration sensor.

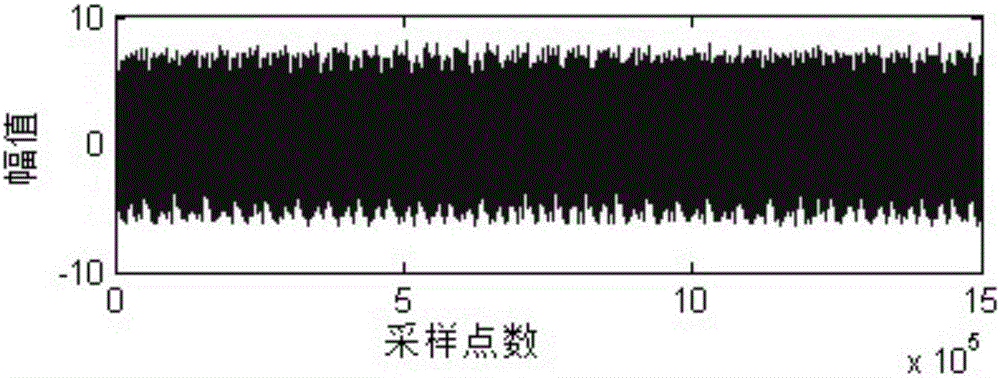

[0053] Step1. Use the acceleration sensor and the charge amplifier to collect the time-domain original vibration signal of the outer ring peeling fault rolling bearing, such as figure 2 shown;

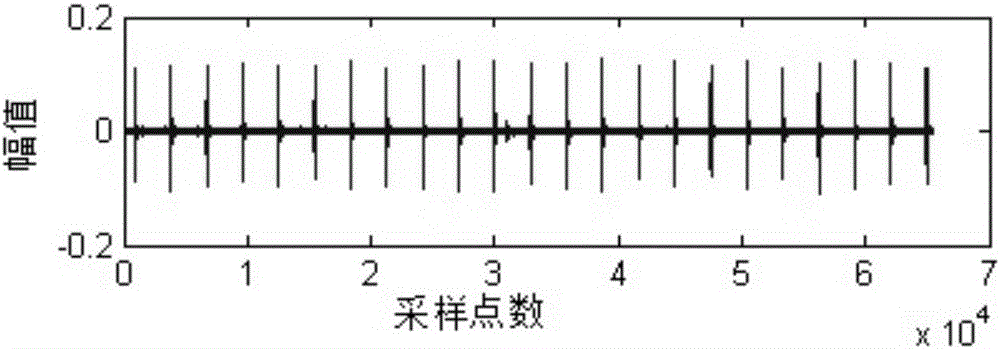

[0054]Step2. Perform noise reduc...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com