Surface-mounted magnetic element and production technology thereof

A magnetic component, surface mount technology, applied in the direction of electrical components, transformer/inductor parts, transformer/reactor installation/support/suspension, etc. Difficult automatic machine realization and other issues, to achieve the effect of high consistency, low production cost, and low material cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

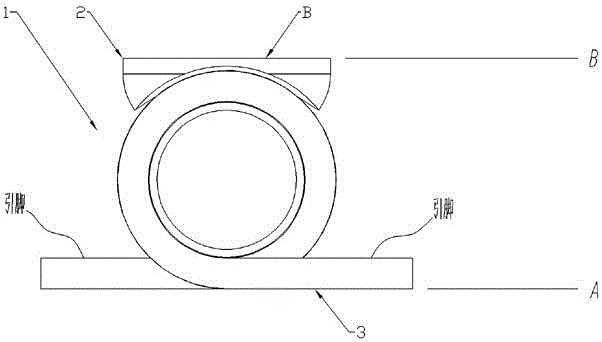

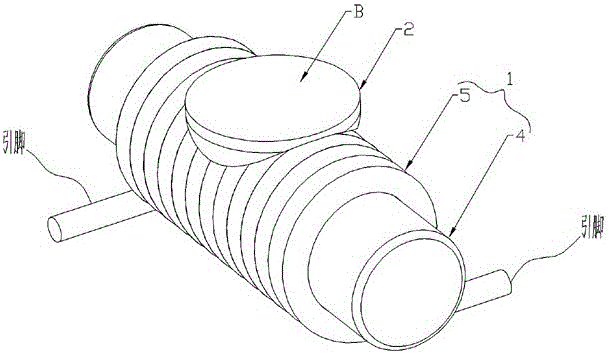

[0023] like figure 1 and figure 2 As shown, in this embodiment, the surface mount magnetic component includes a magnetic component main body 1 and a glue part 2 adhered to the magnetic component main body 1, and all pins of the magnetic component main body 1 The bottom 3 is located on the same horizontal plane A, and the top of the glue part 2 is provided with an adsorption plane B, and the adsorption plane B and the horizontal plane A are parallel to each other.

[0024] In this embodiment, the magnetic element main body 1 includes a magnetic core 4 and a coil 5 wound on the magnetic core 4 , and the glue part 2 is adhered to the coil 5 .

[0025] In this embodiment, the glue part 2 is located above the middle part of the coil 5 .

[0026] In this embodiment, the production process of the surface mount magnetic component includes the following steps:

[0027] a. Set the bottoms 3 of all the pins of the magnetic element body 1 on the same horizontal plane A, and place the ...

Embodiment 2

[0033] In this embodiment, the production process of the surface mount magnetic component includes the following steps:

[0034] a. Set the bottoms 3 of all the pins of the magnetic element body 1 on the same horizontal plane A, and place the magnetic element body 1 on the working plane, and the bottoms 3 of all the pins of the magnetic element body 1 are supported on on said working plane;

[0035] b. Dropping colloidal material on the magnetic element main body 1, so that the colloidal material forms a convex portion on the magnetic element main body 1;

[0036] c. Turn the magnetic element main body 1 over 180°, and then press the top of the colloidal material on the flat plate, so that the top of the colloidal material forms an adsorption plane B, which is parallel to the magnetic The level A in which the bottoms 3 of all pins of the component body 1 lie.

[0037] In this embodiment, the flat plate is a light-transmitting plate, and an ultraviolet light source is arrange...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com