High-capacity transformer oil tank

A transformer oil tank, high-capacity technology, applied in the direction of transformer/inductor cooling, transformer/inductor parts, electrical components, etc., can solve the problems of large heat of the transformer tank casing, increasing the cost of small and medium-sized enterprises, and increasing the volume of the transformer casing. , to reduce the temperature, increase the capacity of the transformer tank, and achieve the effect of simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] In order to make the technical means, creative features, achievement goals and effects realized by the present invention easy to understand, the present invention will be further described below with reference to the specific embodiments.

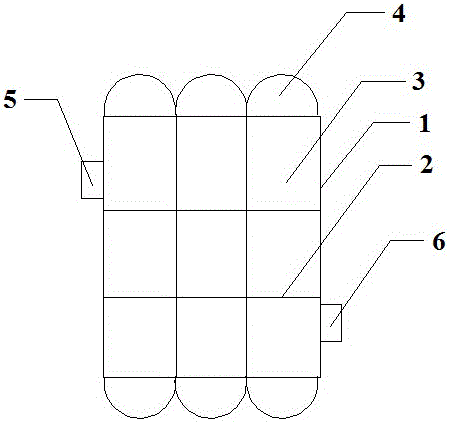

[0014] In order to achieve the above purpose, the present invention is achieved by the following technical solutions: the large-capacity transformer oil tank includes a main body 1, a partition 2, a cavity 3, a raised portion 4, a first heat sink 5 and the second radiator 6, 2 to 4 partitions 2 are installed horizontally inside the main body 1, 2 to 4 partitions 2 are installed vertically inside the main body 1, and the partitions 2 installed horizontally and vertically separate the internal space of the main body 1 There are 9~25 cavities 3, the outer top and bottom of the main body 1 are respectively provided with raised parts 4, the design of the raised parts on the transformer tank shell can greatly increase the capacity of the tr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com