Cold packaging utilized method for manufacturing photovoltaic assembly

A photovoltaic module and component technology, applied in photovoltaic power generation, final product manufacturing, sustainable manufacturing/processing, etc., can solve problems such as difficulty in meeting photovoltaic protection requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] In order to illustrate the method proposed by the present invention more specifically, two detailed implementations are given below.

[0019] Option One:

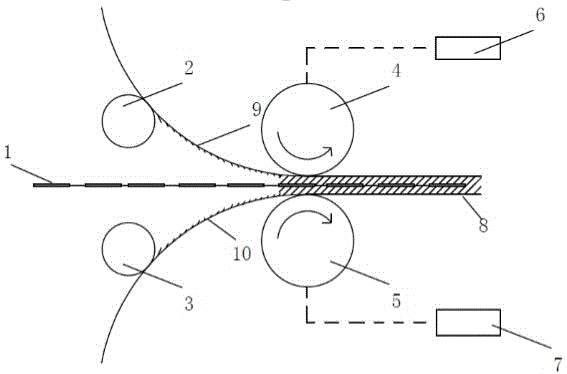

[0020] In an environment with an operating temperature of 25°C, a highly transparent 0.1 mm thick ETFE film is selected as the polymer film 9, a high-quality 0.25 mm thick PET film is selected as the polymer film 10, and a photocell produced by SUNPOWER in the United States is selected as the polymer film 9. Photovoltaic cells 1 of photovoltaic modules. Weld 9 photovoltaic cells into a row, and leave the positive and negative terminals at both ends; use the liquid packaging material 8 developed by the inventor, and adjust the viscosity to 2500CPS; use figure 1 The shown gluing wheels 2 and 3 evenly coat the liquid packaging material 8 on one side of the polymer film 9 and the polymer film 10; along with the synchronous movement of the shaft rollers 4 and 5, the polymer film 9 and the polymer film 10 is laminated on...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com