High-voltage anti-icing device based on wire drawing power generation

A technology of high-voltage wires and anti-icing devices, applied in battery circuit devices, electromechanical devices, circuit devices, etc., can solve problems such as melting ice, low popularity of robots, and high technical level requirements for operators

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0052] Such as Figure 26 , 27 As shown, it includes a first travel actuator 96, a first connection mechanism 97, an energy collection mechanism 98, a second connection mechanism 99, a second travel actuator 100, and a rechargeable battery 101, wherein the first travel actuator 96 and the second The walking actuator 100 is respectively installed on two high-voltage electric wires, and the two ends of the energy collection mechanism 98 are respectively connected with the first traveling actuator 96 and the second traveling actuator 100 through the first connecting mechanism 97 and the second connecting mechanism 99; 101 is installed on the second travel actuator 100 lower side.

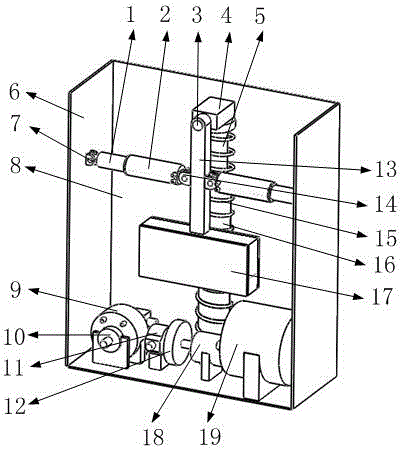

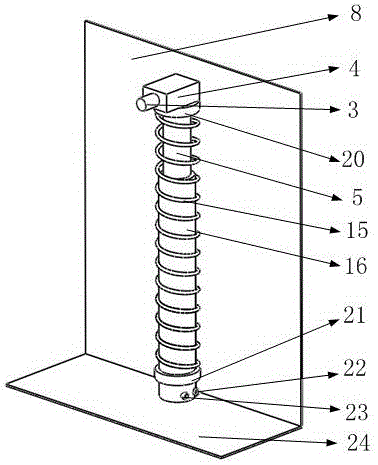

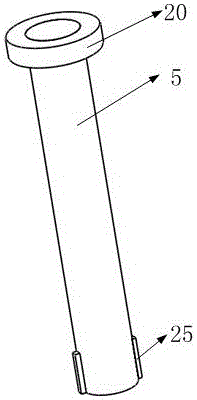

[0053] Such as figure 1As shown, the above-mentioned energy collection mechanism includes a swinging inner rod 1, a swinging outer sleeve 2, a swinging cylindrical pin 3, a swinging support 4, a vibrating inner rod 5, a side wall 6, an inner rod lug 7, a rear wall 8, an air motor 9, a second An over...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com