Making method for front-mid water purifier

A manufacturing method and technology of a water purifier, applied to chemical instruments and methods, water/sewage multi-stage treatment, water/sludge/sewage treatment, etc., to achieve strong sewage interception ability, prevent filter material from escaping, and long service life Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] figure 1 It shows the situation that the water treatment device of the present invention is equipped with manual sewage discharge. For example, for the use of administrative natural villages and concentrated residential areas, the raw water is directly introduced into the device of the present invention for filtration treatment, and the treated water is sent into pure water Available in tank 6.

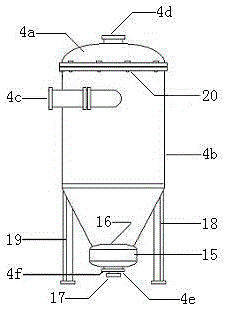

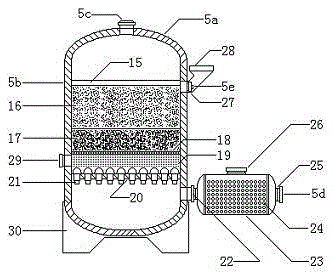

[0015] figure 2 Among them, the cyclone desanding device 4 is a closed container composed of a cone 4b and an upper head 4a, the cone 4b and the upper head 4a are connected by a screw, and the lower part of the airtight container is provided with a conical slag hopper 15, The arc-shaped top of the conical slag hopper is spread all over the slag inlet hole 16, the first landing foot 17 is arranged at the back of the lower part of the airtight container, the second landing foot 18 is arranged on the front right side of the lower part of the airtight container, and the front lef...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com