Advanced treatment method and equipment for printing and dyeing wastewater

A technology for advanced treatment of printing and dyeing wastewater, applied in water/sewage multi-stage treatment, water/sludge/sewage treatment, flocculation/sedimentation water/sewage treatment, etc., can solve problems such as increased turbidity of effluent, achieve load reduction, The removal effect is remarkable and the filter cycle is long

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

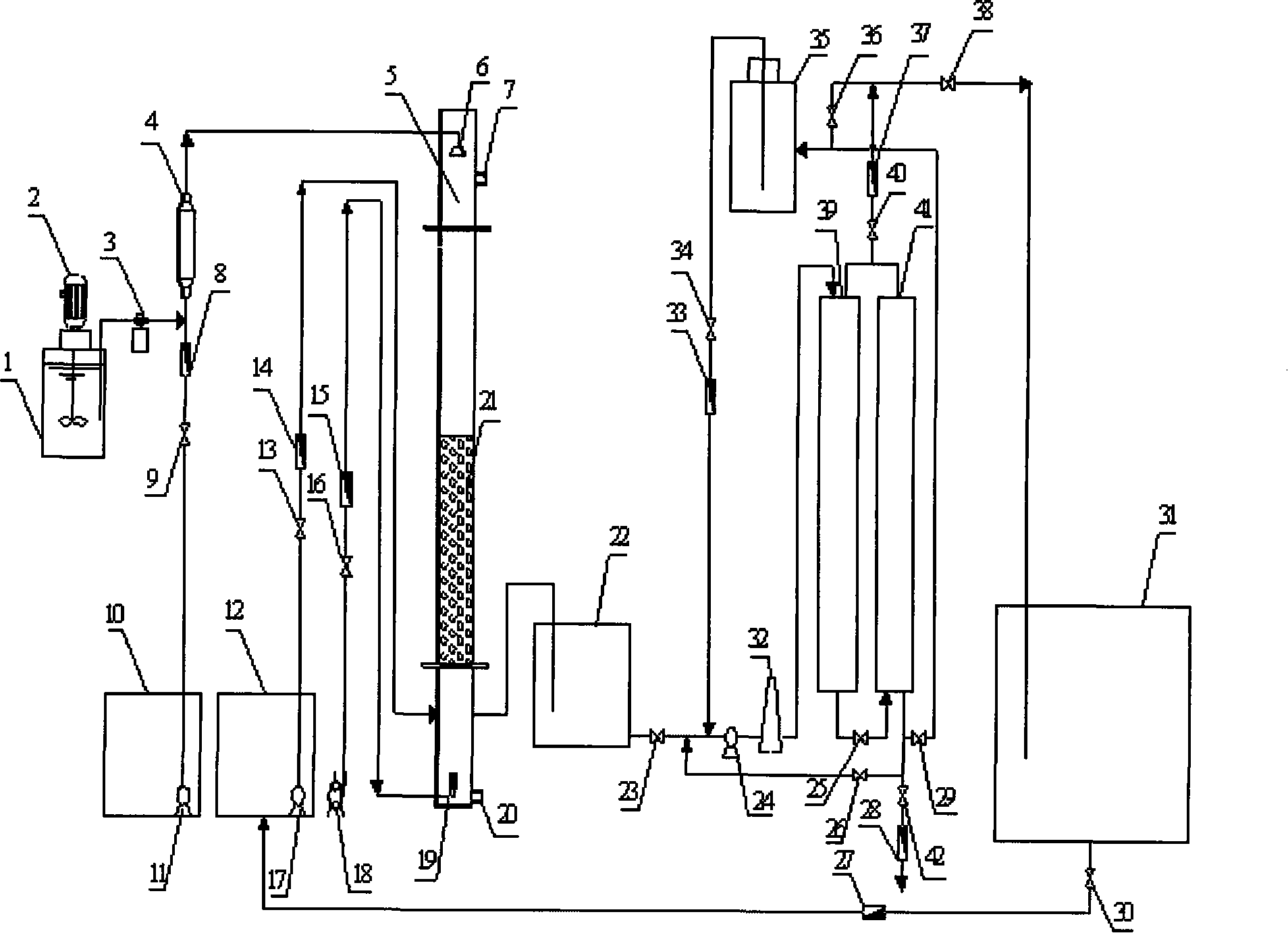

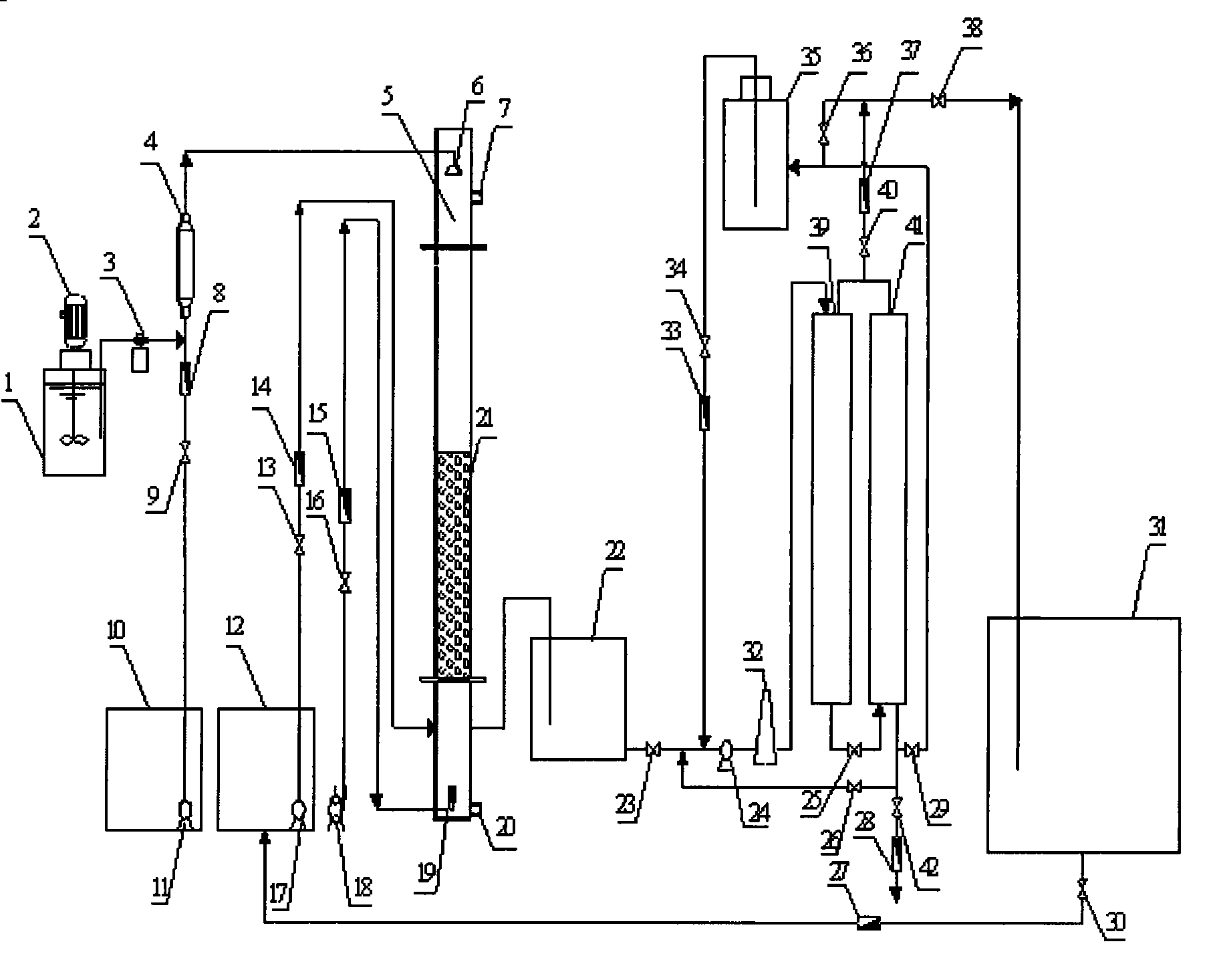

[0029] The waste water to be treated is sucked from the water tank by the lifting pump 11 through the raw water tank 10, and the flocculant is added by the peristaltic pump 3, and mixed with the sucked raw water in the pipeline mixer 4, and the water inlet mode of the pipeline mixer is lateral Flow into the water so that the flocculant and waste water can be mixed quickly and effectively. The mixing time is 6-8s. The mixed effluent directly enters the fiber ball filter column 5 through the connecting pipe. After the effluent enters the water storage tank 22, the pressurized water pump 24 passes through the security filter element 32 , and then enter the ultrafiltration membrane modules 39, 41 through the connecting pipes, the ultrafiltration membrane permeates the water and enters the clean water tank 31, and the concentrated solution can be mixed with the incoming water through the valve 26 and returned to the pressurized water pump 24 before entering the ultrafiltration membra...

Embodiment 2

[0031] The test raw water is taken from the effluent of the aerobic contact oxidation tank of the laboratory printing and dyeing wastewater treatment device. The turbidity of the wastewater is between 52.4 and 93.6 NTU. The chromaticity of the wastewater is mainly produced by the reactive dye reactive red K-2BP. The water passes through the raw water tank 10 by The lifting pump 11 sucks from the water tank, and the flocculant polyaluminum ferric chloride (PAFC) is added by the peristaltic pump 3, and the dosage is 10 mg / L, and mixed with the sucked raw water in the pipeline mixer 4, and the pipeline The water inlet method of the mixer adopts side flow water, so that the flocculant and waste water can be mixed quickly and effectively. The mixing time is 6-8s. The mixed effluent directly enters the fiber ball filter column 5 through the connecting pipe, and the filtration speed is 40m / h , the filtration period is 40 to 48 hours. After the effluent enters the water storage tank 22...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com