Method and device for advanced treatment of printing and dyeing wastewater

A technology for advanced treatment, printing and dyeing wastewater, applied in textile industry wastewater treatment, water/sewage multi-stage treatment, water/sludge/sewage treatment, etc. The effect of strengthening, prolonging the filtration period and reducing the load

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

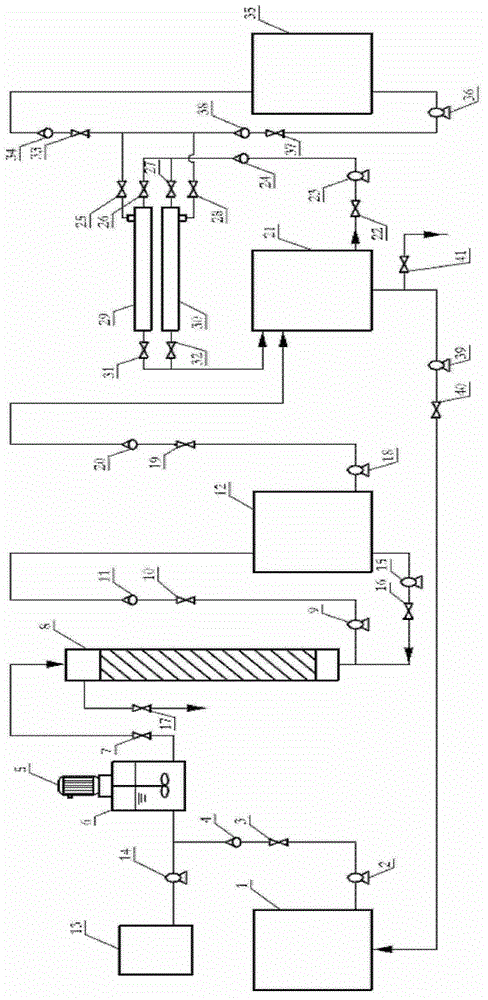

Image

Examples

Embodiment 1

[0058] The wastewater used in the test was effluent from the secondary treatment of printing and dyeing wastewater from a printing and dyeing enterprise in Dongguan City. The turbidity is 5-50NTU, COD Cr It is 15-70mg / L. The raw water is lifted by the pump 2, and its flow rate is controlled by the valve 3 to 50L / h; the coagulant is added by the peristaltic pump 14, and the flow rate is 1mL / min. The raw water and the coagulant are mixed and reacted in the reactor 6, the stirring speed of the agitator 5 is set to 50 rpm, and the hydraulic retention time is 10 minutes. The reacted water passes through the filter column 8 from top to bottom under the suction of the pump 9, and the flow rate is 50 L / h, which is controlled by the valve 10. The filtered water enters the water storage tank 12, and then enters the circulating water tank 21 under the lifting action of the pump 18, and the flow rate is controlled by the valve 19 to be 50L / h, and the water in the circulating water tank e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com