Lithium secondary battery and its manufacturing method and manufacturing device

A lithium secondary battery and manufacturing method technology, applied in the direction of secondary battery, electrolyte battery manufacturing, battery electrodes, etc., can solve problems such as difficulties, many defective products, and a large number of processes, so as to improve the coverage rate and reduce short-circuit defects Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

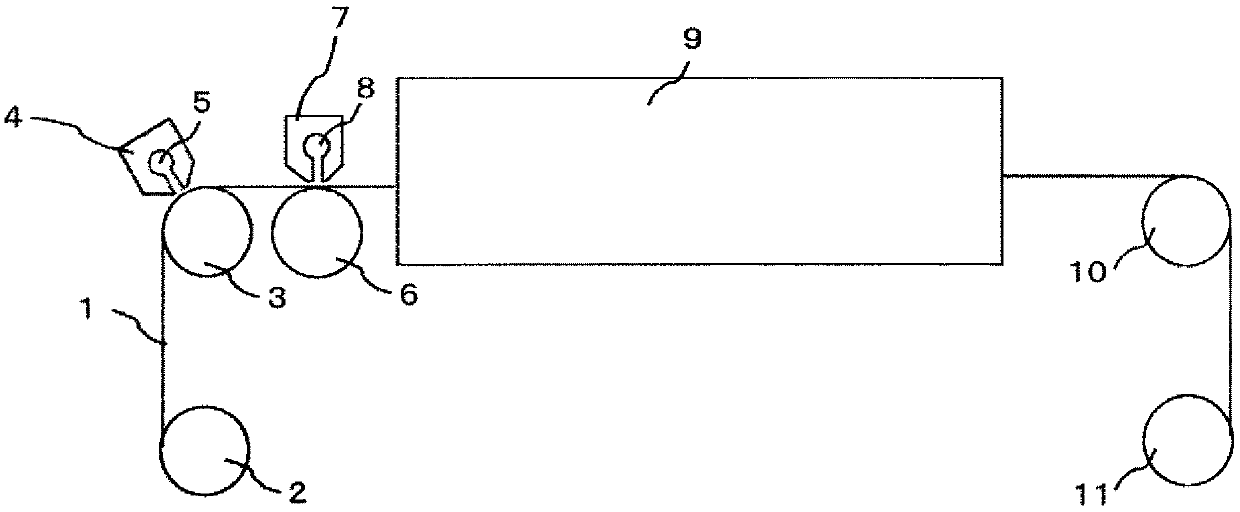

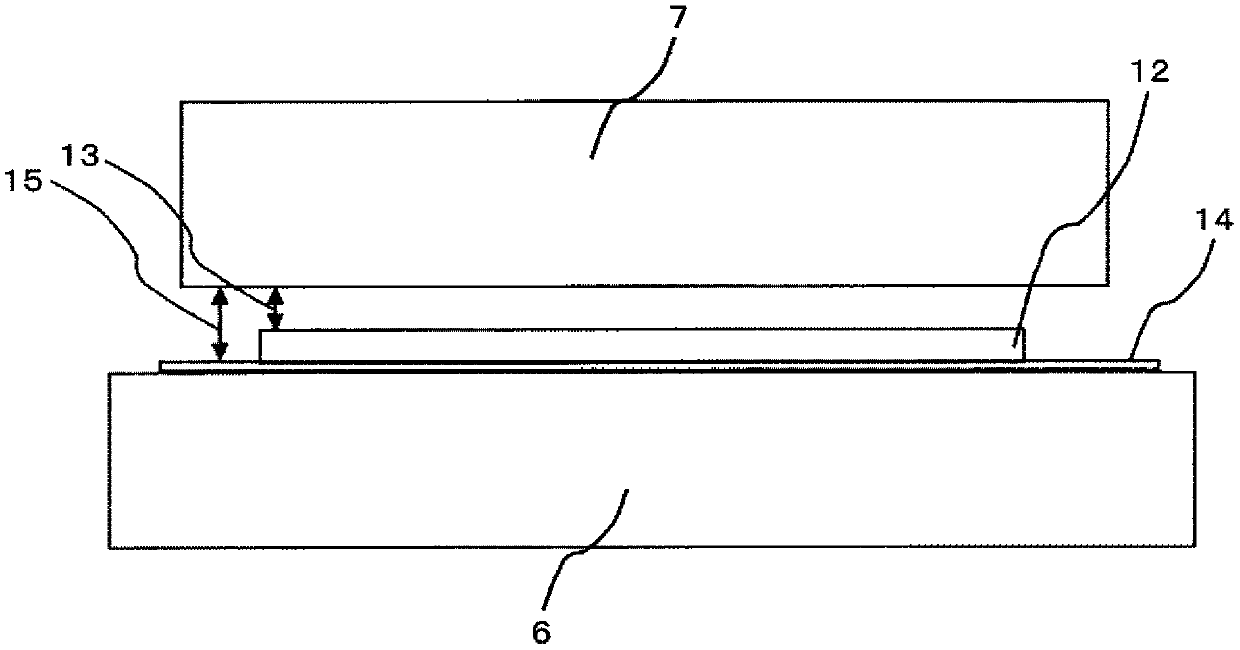

[0040] Figure 5 It is a structural diagram of the manufacturing process of the positive electrode sheet of the lithium secondary battery of this Example. Figure 5 Here, the positive electrode substrate 1 is sent out at a predetermined speed from the positive electrode substrate sending roller 2 as an electrode substrate sending mechanism, and is coated with the positive electrode material 5 and the first insulating material 19 supplied from the die coater 18 facing the roller 3 .

[0041] exist Figure 6 The die coater 18 of this embodiment is shown in . Figure 6 In the process, the positive electrode material 5 is discharged from the die slit 24, and the first insulating material 19 is discharged from the die slit 25 and the die slit 26 provided on both sides of the die slit 24.

[0042] Next, Figure 5 In the downstream, the second insulating material 21 is supplied from the die coater 20 facing the roll 6 . The second insulating material 21 contains a component that ...

Embodiment 2

[0056] This example was performed by replacing the die coater 18 for supplying the positive electrode material 5 and the first insulating material 19 and the die coater 20 for supplying the second insulating material 21 in Example 1 with one die coater. Example This example will be described.

[0057] Figure 8 It is a structural diagram of the manufacturing process of the positive electrode sheet of the lithium secondary battery of this Example. Figure 8 Among them, the positive electrode substrate 1 is sent out at a predetermined speed from the positive electrode substrate sending roller 2 as the electrode substrate sending mechanism, and the positive electrode material 5, the first insulating material 19 and the second insulating material 5 supplied from the die coater 28 opposite to the roller 3 are coated. Material 21.

[0058] Figure 9 The die coater 28 of this embodiment is shown. Figure 9 In the process, the positive electrode material 5 is discharged from the d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com