Air Energy Shoe Dryer

A drying machine and air energy technology, which is applied in the cleaning of boots and shoes, cleaning equipment, household appliances, etc., can solve the problems of slow drying speed, polluted environment, and poor working environment, so as to prevent the indoor temperature from being too high and improve The effect of the work environment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

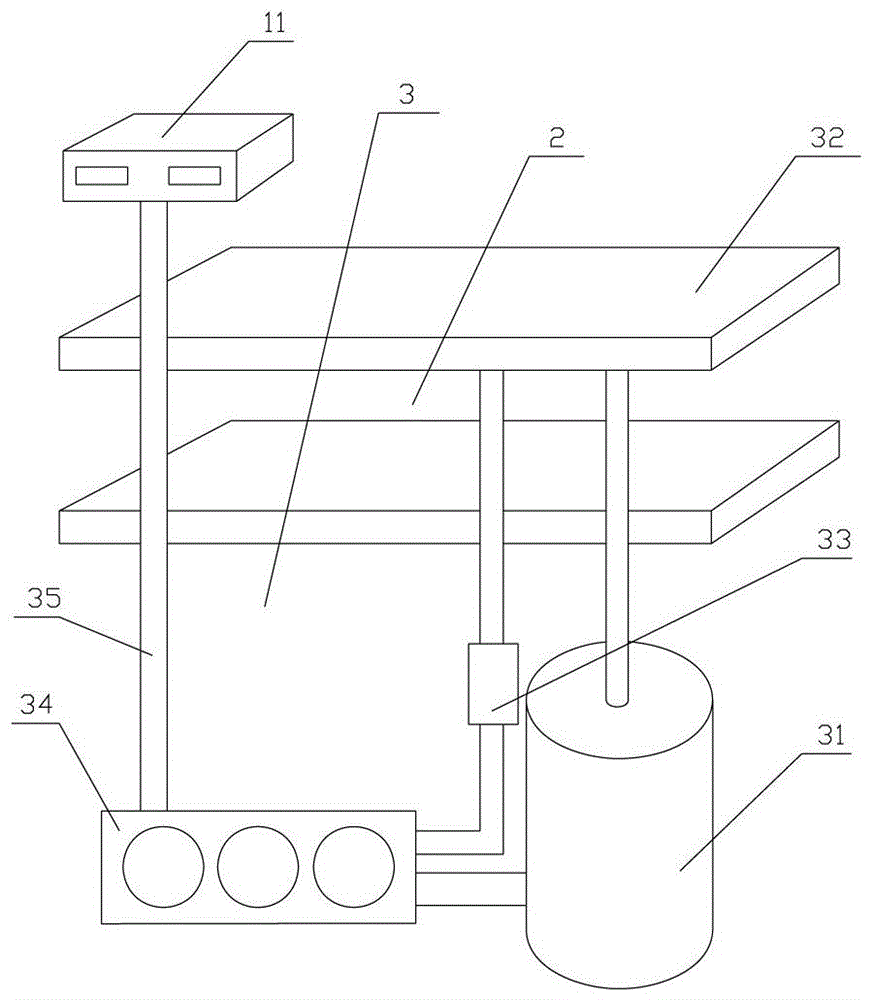

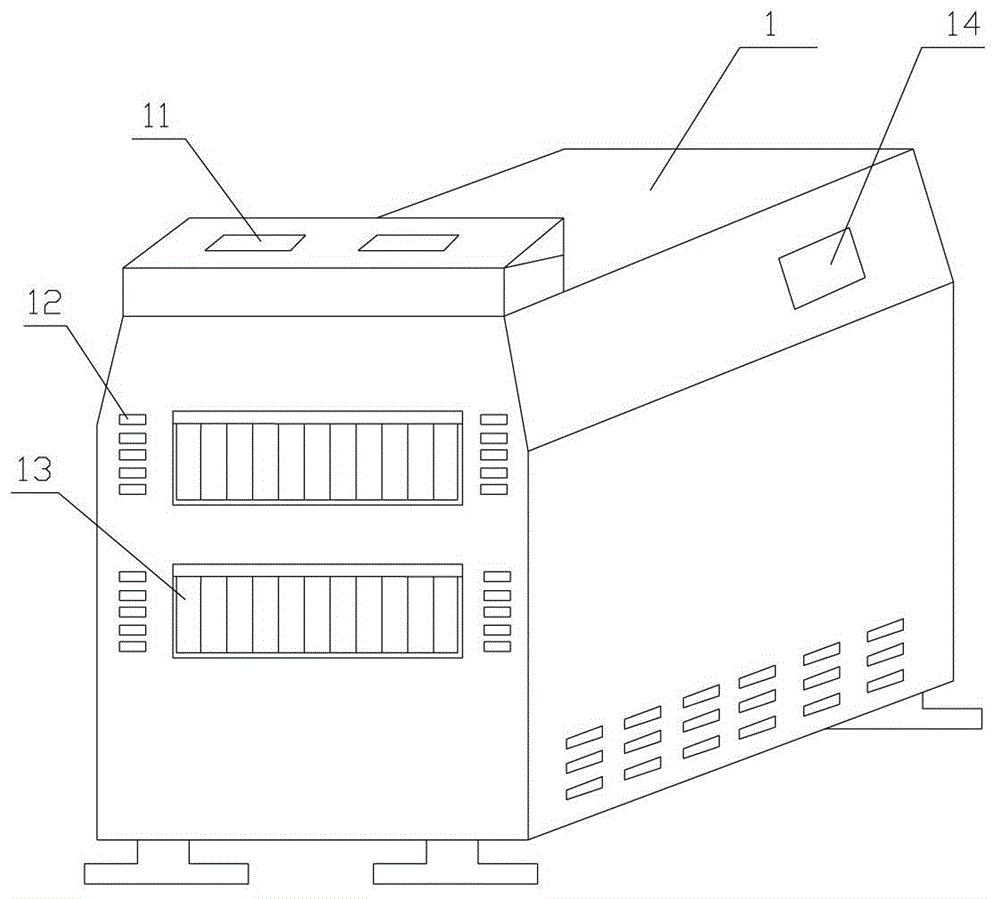

[0018] refer to figure 1 , figure 2 , an air energy shoe dryer, comprising a dryer body 1, a drying chamber 2 and a drying system 3, the surface of the dryer body 1 is provided with cooling holes 12, and the drying system 3 is composed of a compressor 31, a condensing 32, throttling device 33 and evaporator 34, the drying chamber 2 is divided into upper and lower layers, the drying chamber 2 runs through the dryer body 1, the condenser 32 is installed on the top of the drying chamber 2, so The compressor 31 , the condenser 32 , the throttling device 33 and the evaporator 34 are connected, and the evaporator 34 is communicated with the cold air outlet 11 through the air pipe 35 , and the cold air outlet 11 is arranged on the top of the dryer body 1 .

[0019] The invention is refitted according to the structure of the air conditioner, and utilizes the heat and cold generated by the air generated by the liquefaction and vaporization of the refrigerant in the drying system to d...

no. 2 example

[0021] refer to figure 1 , figure 2 , an air energy shoe dryer, comprising a dryer body 1, a drying chamber 2 and a drying system 3, the surface of the dryer body 1 is provided with a heat sink 12, and the drying system 3 is composed of a compressor 31, a condenser 32. It is composed of throttling device 33 and evaporator 34. The drying chamber 2 is divided into upper and lower layers. The drying chamber 2 runs through the dryer body 1. There is a black high-temperature-resistant cloth curtain 13, which can effectively prevent the temperature in the drying chamber 2 from dissipating. The dryer body 1 is provided with a temperature monitoring device 14, which can monitor the temperature in the drying chamber 2 at any time to prevent the indoor temperature from being too high. Timely and effective alarm, the condenser 32 is installed on the top of the drying chamber 2, the compressor 31, the condenser 32, the throttling device 33 and the evaporator 34 are connected, and the ev...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com