Automatic assembly process of precise filter part in precise infusion device

A precision filter, automatic assembly technology, applied in the direction of assembly machines, manufacturing tools, metal processing equipment, etc., can solve problems such as the assembly process of precision filters and catheters that are not mentioned

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0039] Such as Figure 1-10 As shown, the automatic assembly process of the precision filter part in a kind of precision infusion set provided in the present embodiment, it comprises:

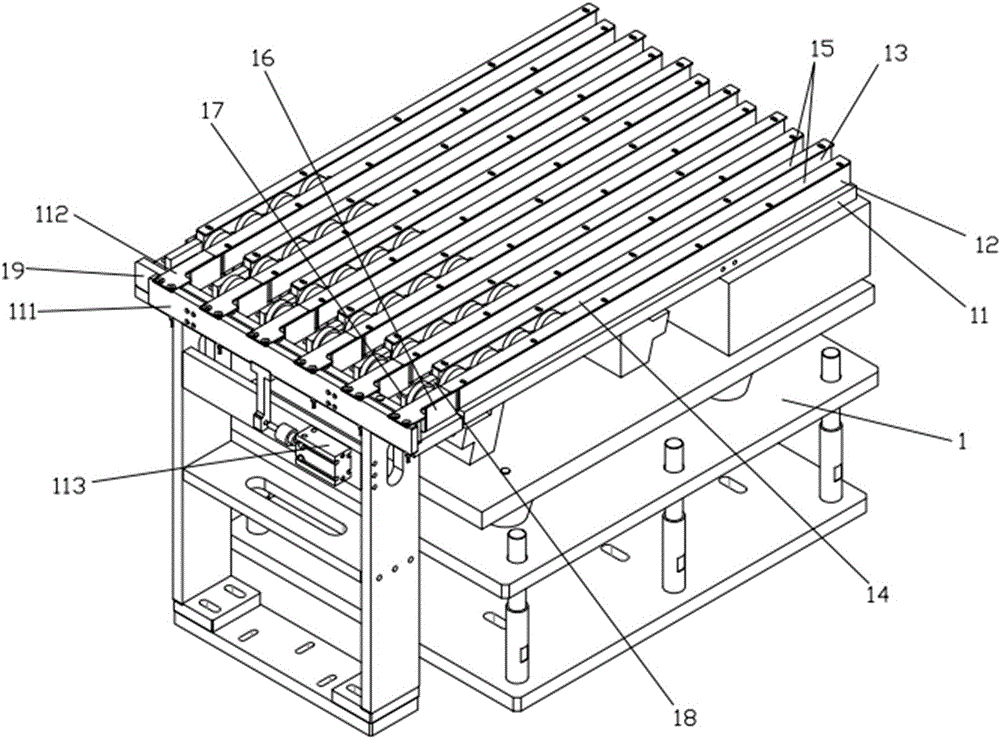

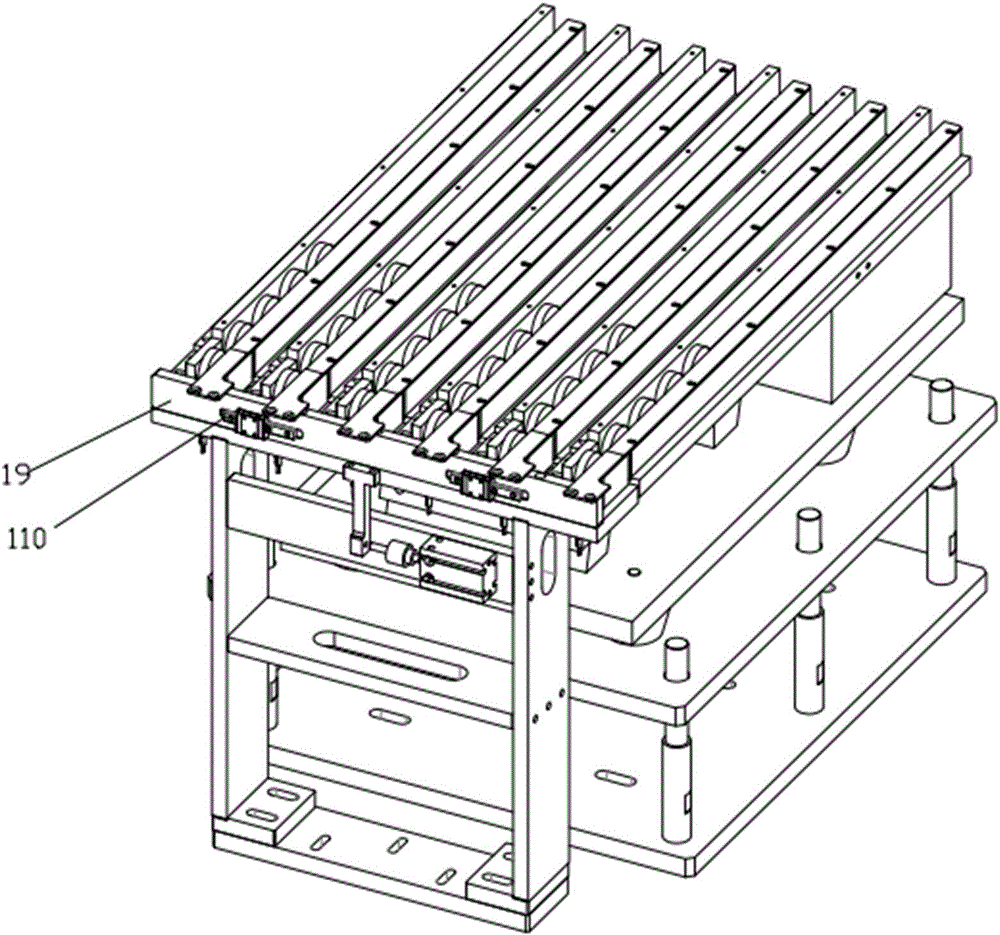

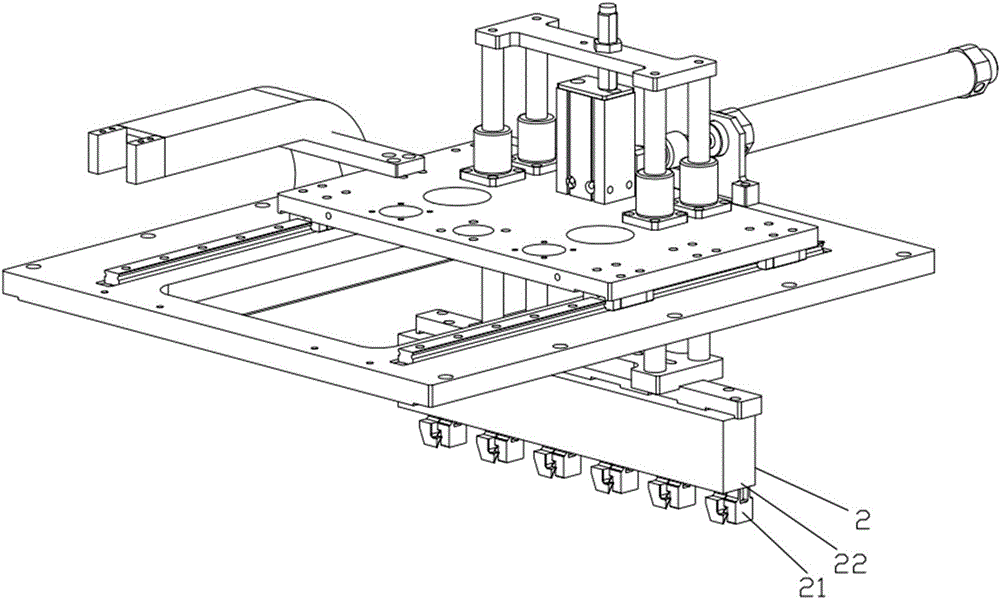

[0040] a. The feeding step of the precision filter; adopt a discharge and flat delivery device 1 and a set of reclaiming manipulator assembly 2; The first limiting block 12 and the second limiting block 13 arranged at a word interval in the horizontal direction of space, wherein the first limiting block 12 and the second limiting block 13 are distributed alternately, and each adjacent group The first limit block 12 and the second limit block 13 jointly form a horizontal feed and discharge channel 14 for conveying precision filters, and the second limit block 13 is provided with a pair of horizontal feed and discharge channels 14 Block the opening of the horizontal feed and discharge channel 14 to prevent the precision filter from coming out of the first pressure plate 15, and one side port of ...

Embodiment 2

[0055] The automatic assembly process of the precision filter part in a precision infusion set provided in this embodiment, its general steps are consistent with embodiment 1, but in order to monitor in real time through the precision filter in a precision infusion set provided by the present invention The joint sealing between the liquid inlet flow channel and the liquid inlet conduit on the precision infusion device assembled by the automatic assembly process of the device part, as well as the joint sealing between the liquid outlet flow channel and the infusion catheter, the precise infusion device provided in this embodiment The automatic assembly process of the filter part, which also includes: g, the detection step of the finished product; carry out the ventilation test and the sealing test on the precision infusion set assembly assembled in the above step d, and judge the gap between each component by the air pressure value in the infusion set Check whether there is bloc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com