Manufacturing method of colorful zipper

A manufacturing method and zipper technology, which is applied in the field of zippers, can solve problems such as the assembly efficiency of a single zipper slider in a zipper style, and achieve the effects of increasing color diversity, improving assembly efficiency, and accelerating material return speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0047] The following are specific embodiments of the present invention in conjunction with the accompanying drawings to further describe the technical solutions of the present invention, but the present invention is not limited to these embodiments.

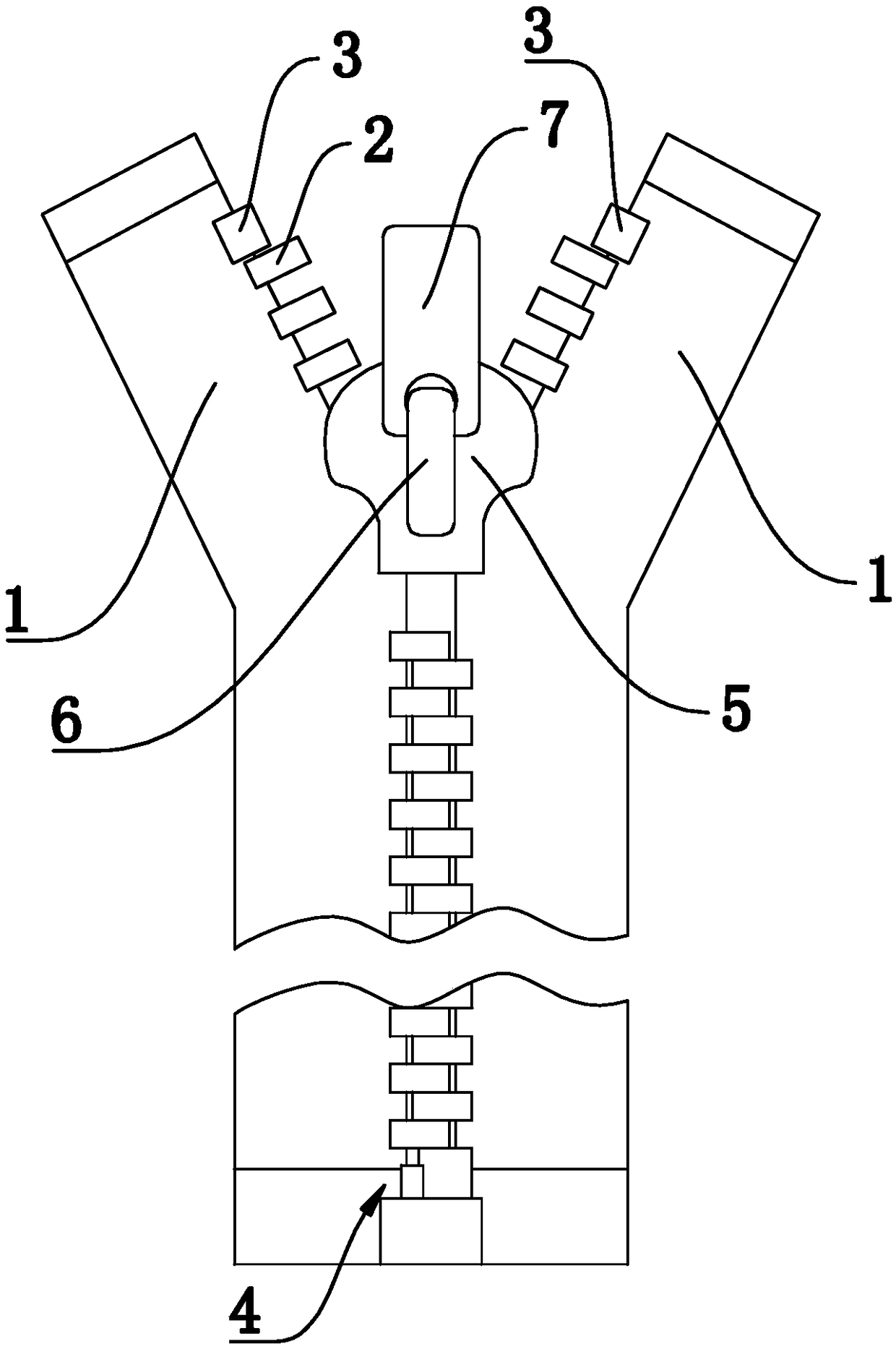

[0048] Such as figure 1 As shown, a colorful zipper includes two chain belts 1 and a zipper head. The opposite side edges of the two chain belts 1 are provided with chain teeth 2. The zipper head enables the chain teeth 2 on the two chain belts 1 to engage and Separate, the two chain belts 1 are printed with multiple colors or patterns.

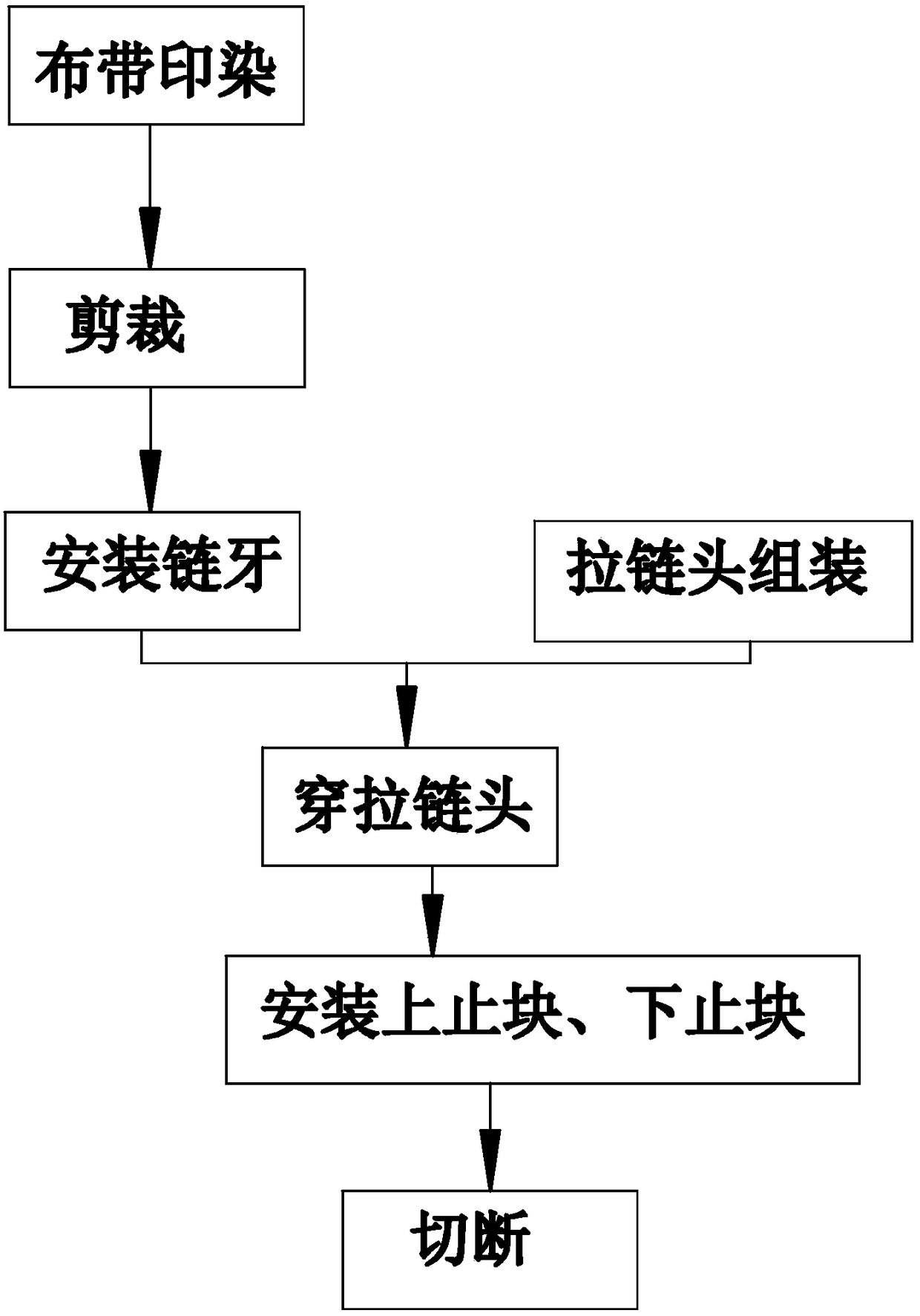

[0049] Such as Figure 2 to Figure 6 As shown, the present invention provides a method for manufacturing a colorful zipper, which includes the following steps:

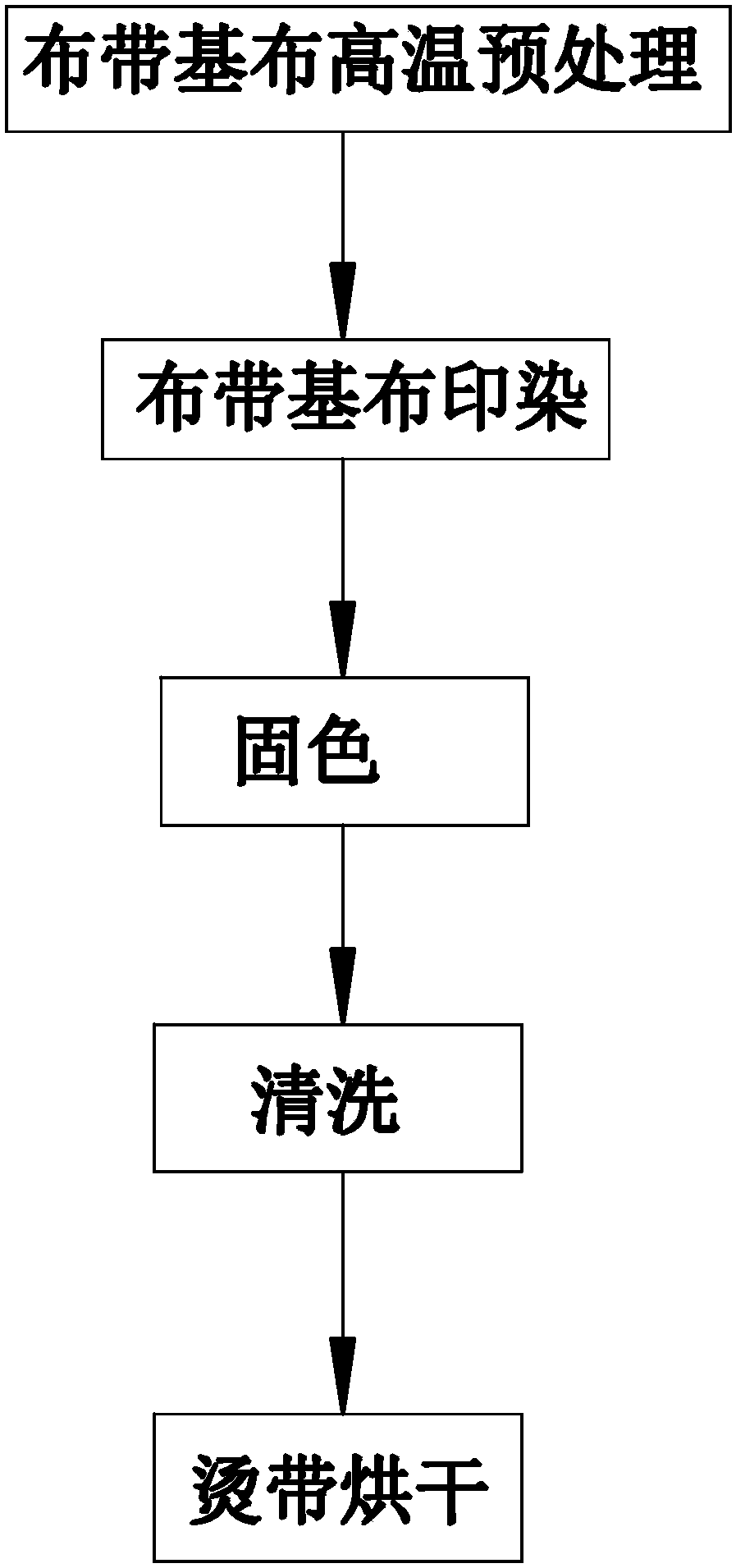

[0050] A. Perform printing and dyeing treatment on the cloth tape to make at least one side of the cloth tape show multiple colors or patterns with multiple colors; cut it into two matching strips along the center line of the cloth tape, and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com