Double-faced cement-based rock wool composite plate

A composite board, cement-based technology, applied in the direction of hydraulic material layered products, building components, applications, etc., can solve the problems of fixed style and inability to change, so as to improve the bonding strength and increase the convenience of construction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

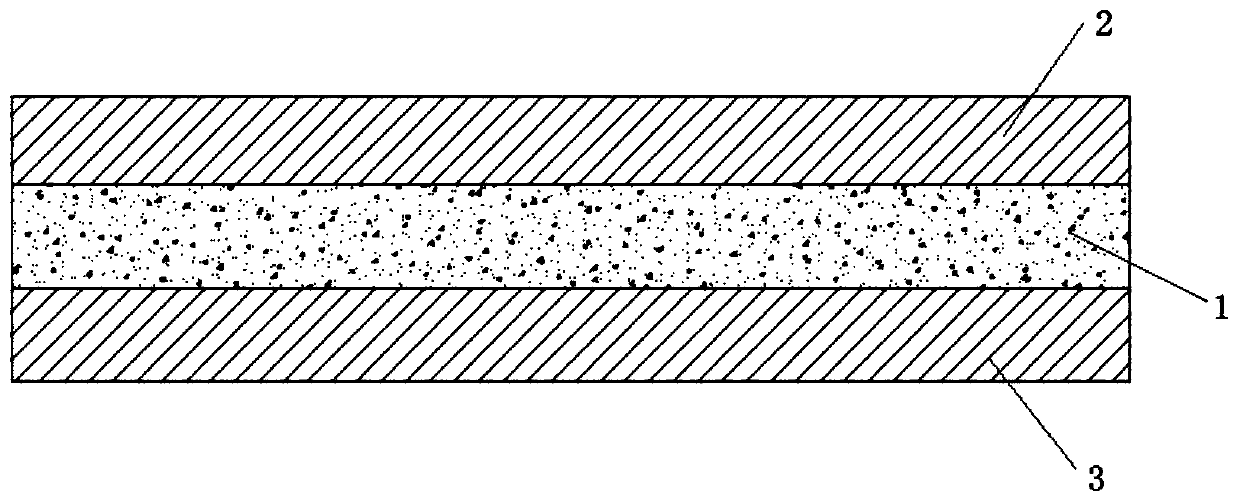

[0023] Embodiment one, such as figure 1 As shown, a double-sided cement-based rock wool composite board according to an embodiment of the present invention includes a rock wool layer 1, and the two sides of the rock wool layer 1 are respectively provided with a first reinforced glass fiber cement-based thin felt layer 2 And the second reinforced glass fiber cement-based thin mat layer 3. The rock wool layer 1 has better thermal insulation effect, lighter weight, and cheap price, so it is a suitable thermal insulation material. Both sides of the rock wool layer 1 are provided with reinforced glass fiber cement-based thin felt layers. The reinforced glass fiber cement-based thin felt layer and the cement of the wall belong to the same material, and the bonding strength between the same materials is high, which effectively improves the thermal insulation effect. The installation strength of the board is not easy to fall off. In actual use, the first reinforced glass fiber cemen...

Embodiment 2

[0024] Embodiment two, on the basis of embodiment one, the rock wool layer 1 is bonded to the first reinforced glass fiber cement-based thin felt layer 2 and the second reinforced glass fiber cement-based thin felt layer 3 by glue combine. It is more convenient to manufacture and produce through glue bonding, with high production efficiency, fewer processes and low cost. And the strength of bonding can also meet the requirements. At the same time, it will not cause structural damage to the double-sided cement-based rock wool composite board and cause water leakage. In this embodiment, PU-50 type two-component polyurethane adhesive is selected, which can be used for bonding steel plates, aluminum plates, aluminum-plastic plates, calcium silicate plates, ceramics, marble, etc. The biggest advantage of the board is that it is resistant to water and cold and has a certain toughness.

Embodiment 3

[0025] Embodiment 3, on the basis of Embodiment 1 or 2, a first fireproof layer is provided between the rock wool layer 1 and the first reinforced glass fiber cement-based thin felt layer 2 . Many existing insulation boards do not have the effect of fire prevention. Once a fire occurs, they will burn upwards along the insulation boards, producing strong smoke and dust, causing serious consequences. This embodiment is provided with the first fireproof layer, which can make the double-sided cement-based rock wool composite board play the fireproof effect, and will not increase the fire intensity in the event of a fire, so as to avoid the overall shedding of the insulation board caused by the fire on the outer facade.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com