Controllable preparation method for silica-gel chromatographic filler

A silica gel chromatography, silica gel technology, applied in chemical instruments and methods, other chemical processes, etc., to avoid the use of organic reagents

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

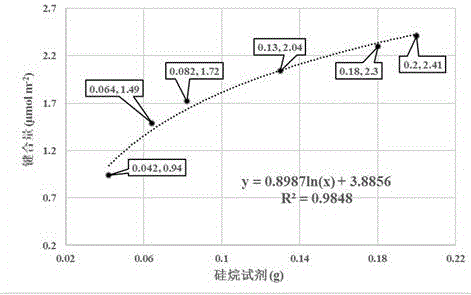

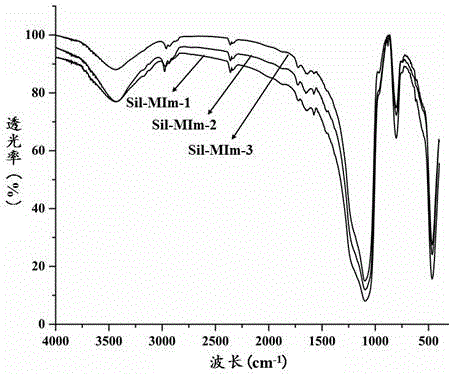

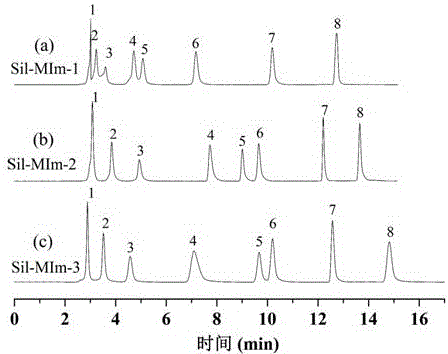

[0028] N - Preparation of Methylimidazole Silica Gel Chromatography Packing (Sil-MIm)

[0029] Steps:

[0030] ① First weigh 0.5 g of silica gel and 0.04 g of CPTMS into a 25 mL round bottom flask, and then add 10 mL of bonded monomer MIm into it;

[0031] ② The mixture of silica gel, silane reagent CPTMS and bonded monomer MIm in a certain proportion was reacted for 48 h at 120 °C under magnetic stirring;

[0032] ③ After the reaction, the prepared chromatographic material was washed several times with a small amount of methanol and then with a large amount of water, and then dried in a vacuum oven for 12 h.

Embodiment 2

[0034] N - Preparation of Methylimidazole Silica Gel Chromatography Packing (Sil-MIm)

[0035] Steps:

[0036] ① First weigh 0.5 g of silica gel and 0.06 g of CPTMS into a 25 mL round bottom flask, and then add 10 mL of bonded monomer MIm into it;

[0037] ② The mixture of silica gel, silane reagent CPTMS and bonded monomer MIm in a certain proportion was reacted under magnetic stirring at 60 °C for 48 h;

[0038] ③ After the reaction, the prepared chromatographic material was washed several times with a small amount of methanol and then with a large amount of water, and then dried in a vacuum oven for 12 h.

Embodiment 3

[0040] N - Preparation of Methylimidazole Silica Gel Chromatography Packing (Sil-MIm)

[0041] Steps:

[0042] ① First weigh 1.0 g of silica gel and 0.04 g of CPTMS into a 25 mL round bottom flask, and then add 10 mL of bonded monomer MIm into it;

[0043] ② The mixture of silica gel, silane reagent CPTMS and bonded monomer MIm in a certain proportion was reacted for 48 h at 120 °C under magnetic stirring;

[0044] ③ After the reaction, the prepared chromatographic material was washed several times with a small amount of methanol and then with a large amount of water, and then dried in a vacuum oven for 6 h.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com