Complete equipment for automatic garbage sorting

A technology of automatic sorting and complete sets of equipment, applied in solid separation, packaging, unsealing of packaging objects, etc., can solve the problems of high maintenance cost, large size distribution of over- and under-sieve objects, and poor garbage sorting effect. To achieve the effect of low operation and maintenance costs, good classification and treatment effect, and good preliminary sorting effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

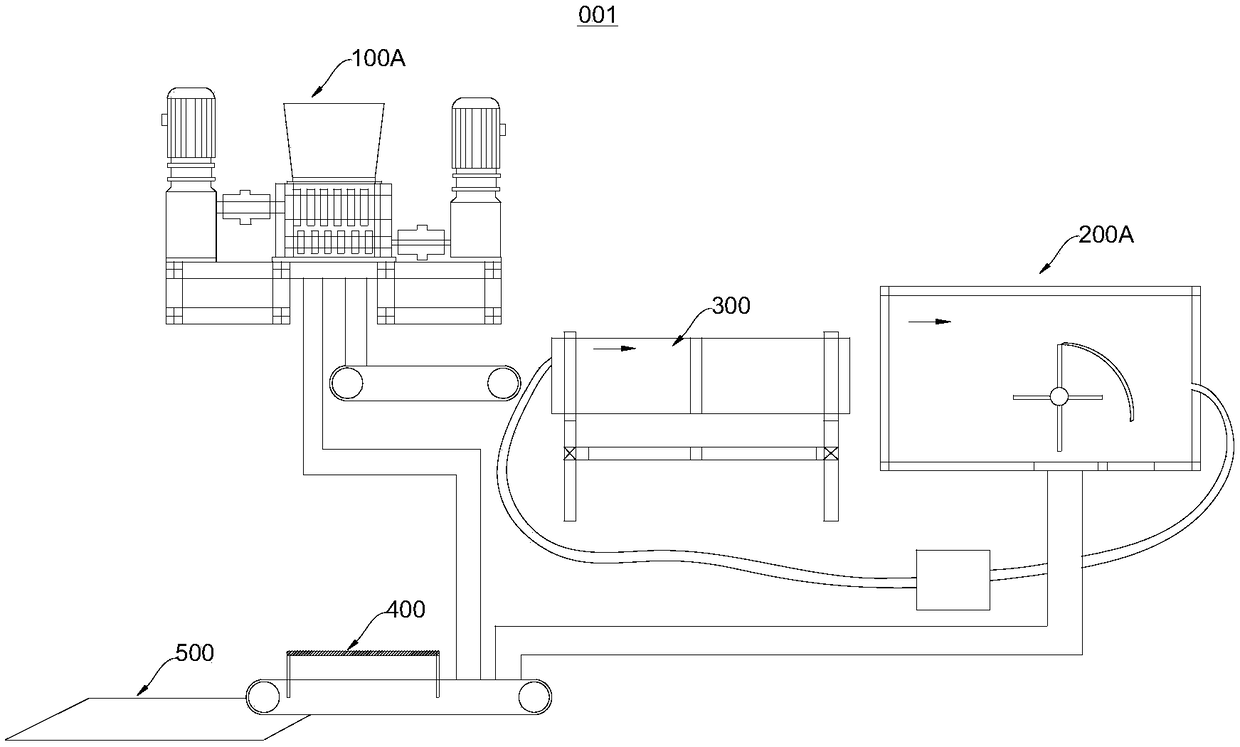

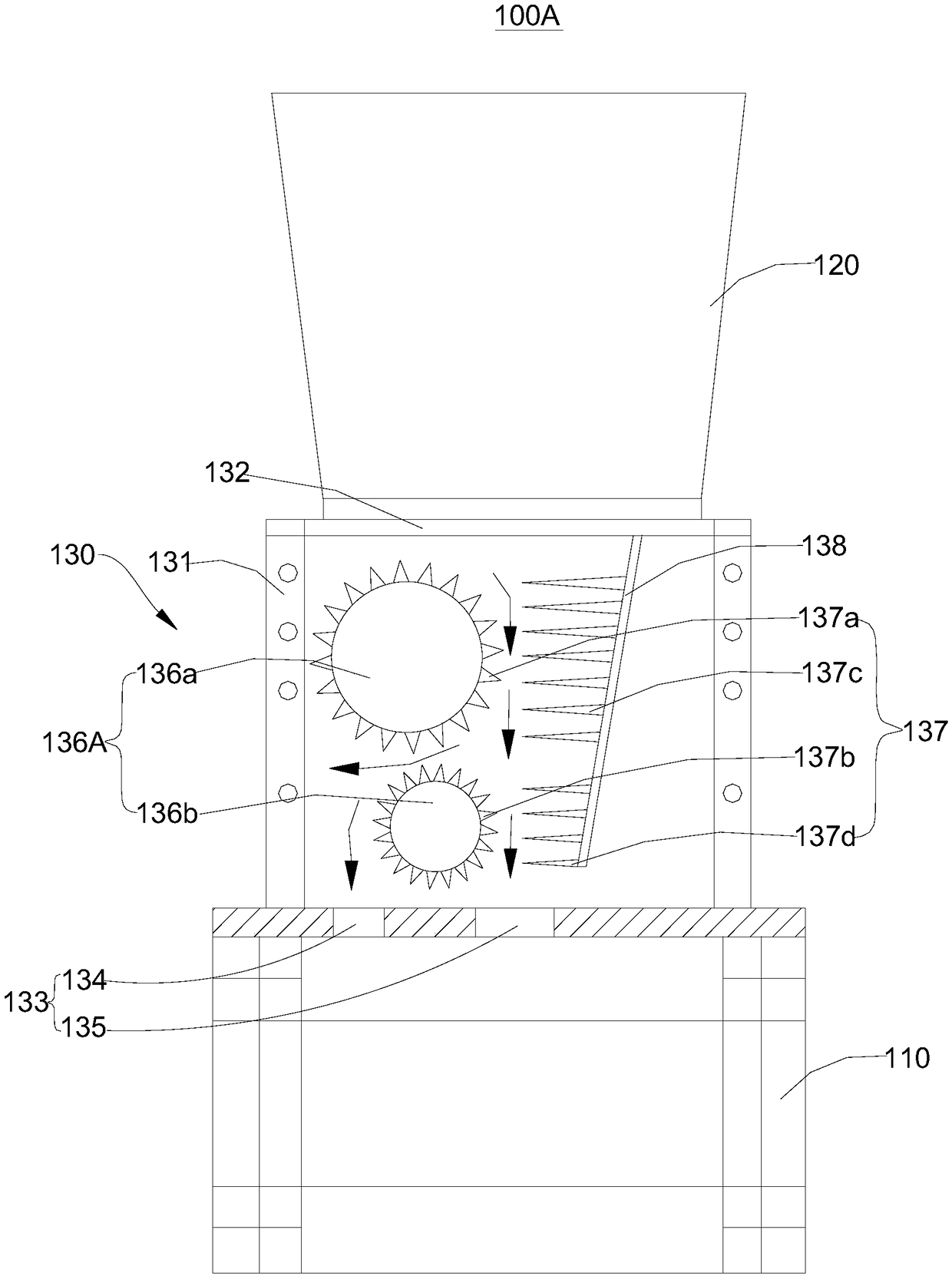

[0035] see figure 1 , this embodiment provides a complete set of garbage automatic sorting equipment 001, which includes a bag breaking primary selection mechanism 100A, a negative pressure rolling sorting mechanism 300, a negative pressure adsorption sorting mechanism 200A, a magnetic suction sorting mechanism 400 and a metal detection manual Auxiliary sorting mechanism 500. The discharge end of the bag breaking primary selection mechanism 100A is connected with the feed end of the negative pressure rolling separation mechanism 300, and the discharge end of the negative pressure rolling separation mechanism 300 is connected with the feed end of the negative pressure adsorption separation mechanism 200A. Both the bag primary selection mechanism 100A and the negative pressure adsorption separation mechanism 200A are connected to the magnetic suction separation mechanism 400 , and the magnetic suction separation mechanism 400 is connected to the metal detection artificial auxili...

no. 2 example

[0079] see Figure 7 , this embodiment provides a complete set of garbage automatic sorting equipment 002, which includes a bag breaking primary selection mechanism 100B, a negative pressure adsorption sorting mechanism 200B, a negative pressure rolling sorting mechanism 300, a magnetic suction sorting mechanism 400 and a metal detection manual Auxiliary sorting mechanism 500.

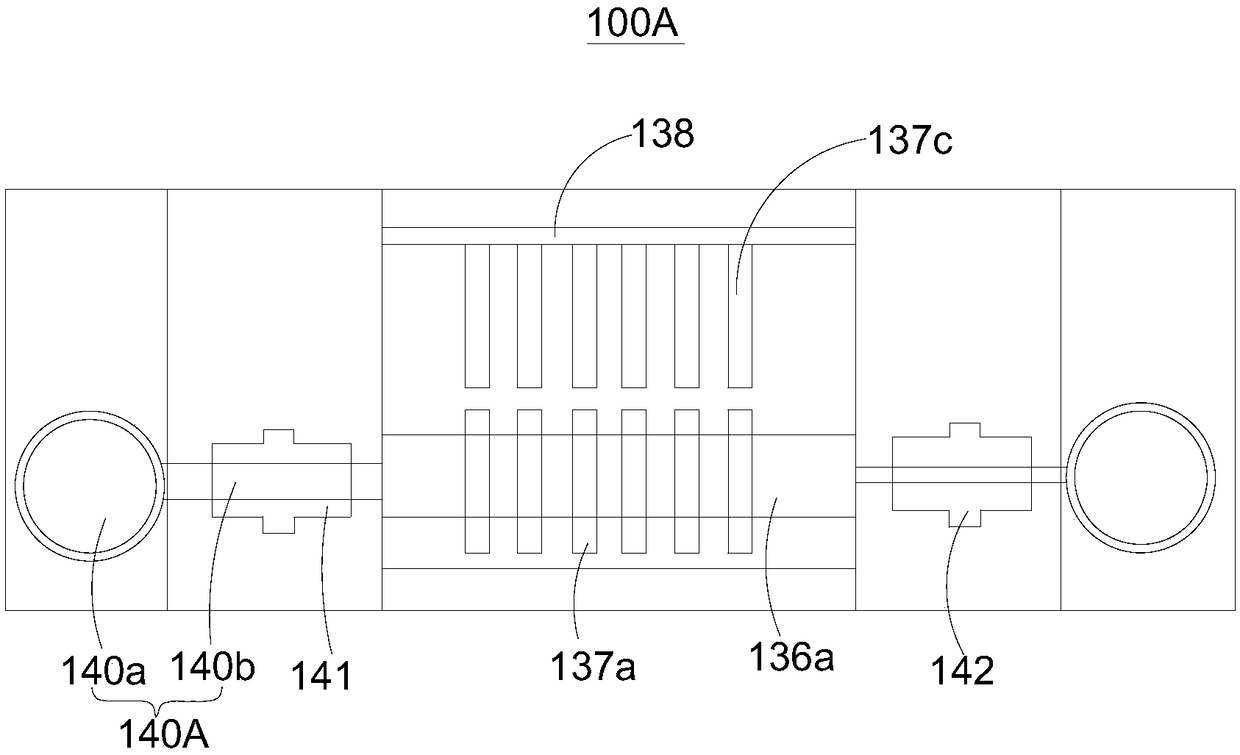

[0080] see Figure 8 and Figure 10 , which is roughly the same as the garbage automatic sorting complete set 001 of the first embodiment, the difference between the two is: the third cutter 137c and the fourth The cutter 137d is preferably connected to the first housing 131 by a roller, and the third cutter 137c and the fourth cutter 137d are fixed to the third roller 136c and the fourth roller 136d respectively; The negative pressure adsorption separation mechanism 200B also includes a grid windmill 250 .

[0081] see Figure 8 and Figure 9 In this embodiment, the rotating assembly 136B also i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com