An integrated transfer station for garbage sorting and processing

A garbage sorting and transfer station technology, which is applied in garbage cans, garbage delivery, garbage collection, etc., can solve the problem that garbage sorting equipment is not suitable for domestic garbage, and achieve the effect of easy follow-up processing, exquisite structure, and reduced volume

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The preferred technical solutions of the present invention will be described in detail below in conjunction with the accompanying drawings.

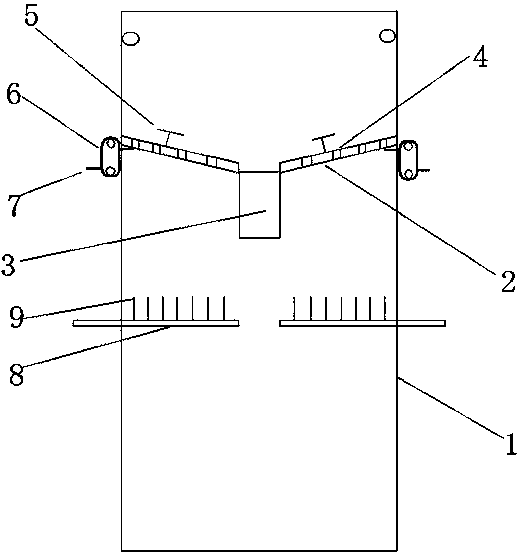

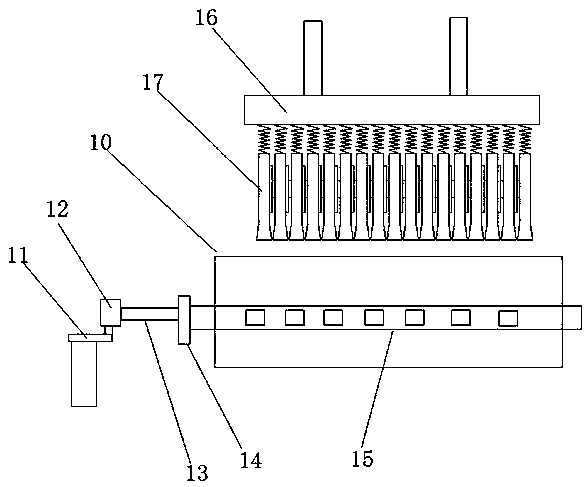

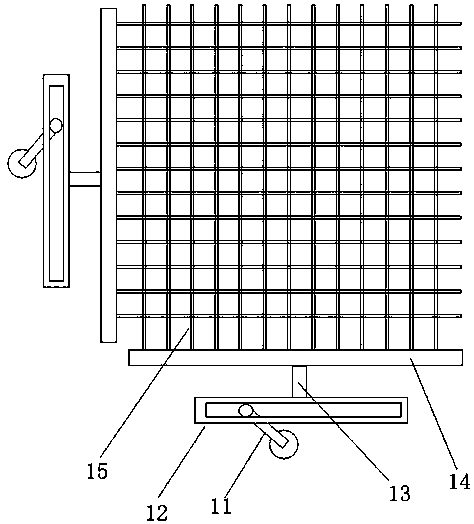

[0027] As shown in the figure, a waste sorting and processing integrated transfer station of the present invention includes a waste sorting device and a waste cutting device;

[0028] The garbage sorting device includes a sorting barrel 1 with an opening at the top, and a filter layer 2 is arranged in the sorting barrel 1 close to the upper opening, and the center of the filter layer 2 has a drop opening 3 for large solid waste to pass through. On the filter layer 2, a plurality of filter openings 4 through which small garbage is distributed and a cutting device 5 for cutting small garbage;

[0029] Further, the cutting device 5 is a blade parallel to the filter layer 2, and the cutting device 5 is 25cm-10cm away from the filter layer;

[0030] Further, the height of the filter layer 2 close to the inner wall of the classificatio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com