A continuous processing device and processing method for ultrafine-grained metal profiles

A technology of metal profiles and processing devices, which is applied in the field of continuous processing devices and devices for continuous processing of ultra-fine-grained metal profiles. Good industrial application prospects, improved follow-up molding capabilities, and reduced production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

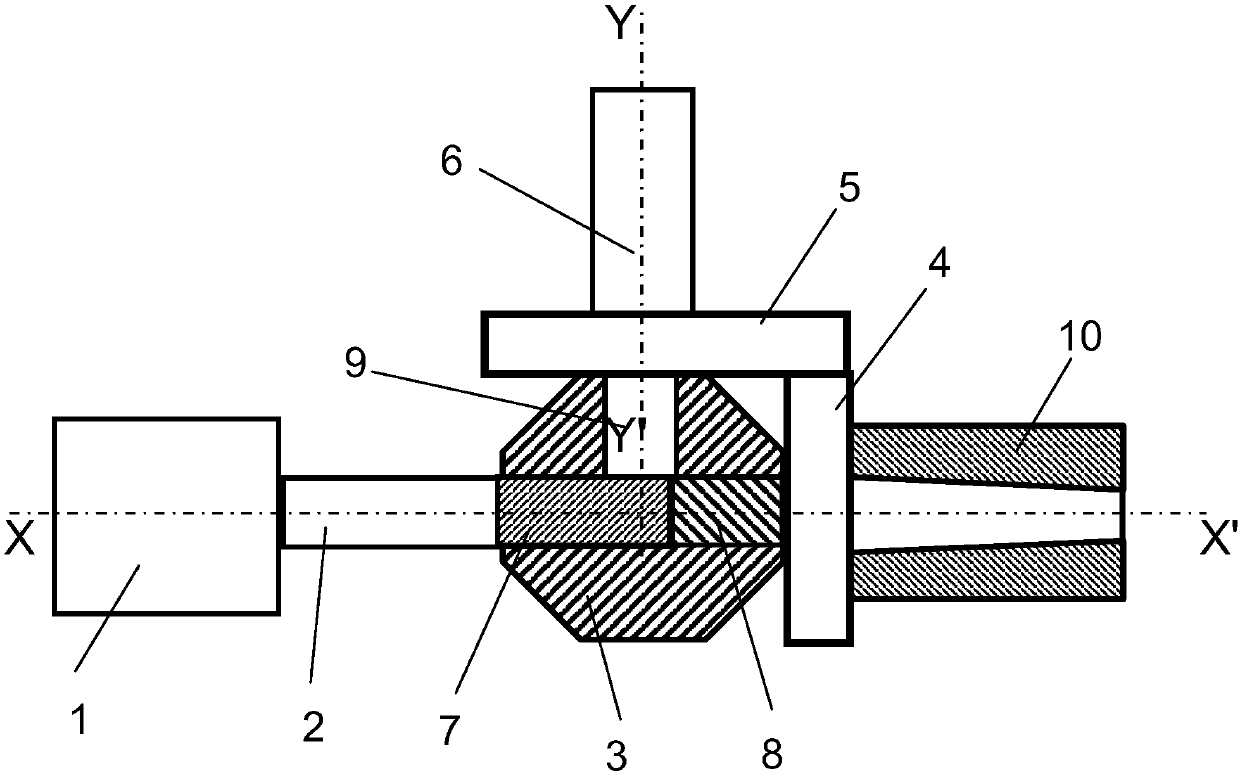

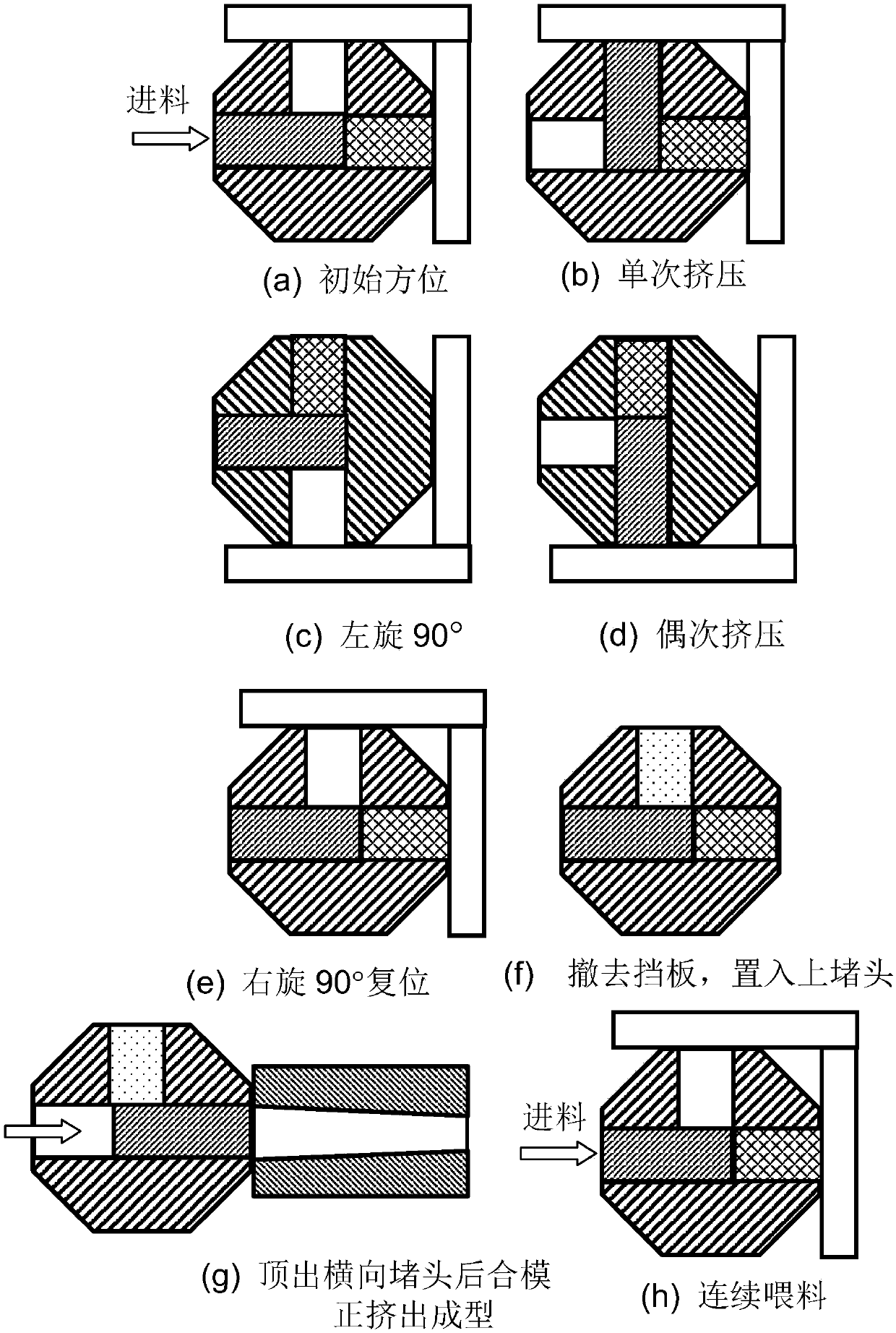

[0031] Attached below figure 1 , figure 2 and image 3 And preferred embodiment the present invention is described in further detail.

[0032] Such as figure 1 and figure 2 As shown, the continuous processing device of the ultra-fine-grained metal profile of the present invention includes a single-screw extruder 1, an extrusion rod 2, an octagon corner extrusion die 3, a transverse baffle 4, a longitudinal baffle 5, a guide frame 6, Transverse plug 8, vertical plug 11 and positive extrusion molding die 10.

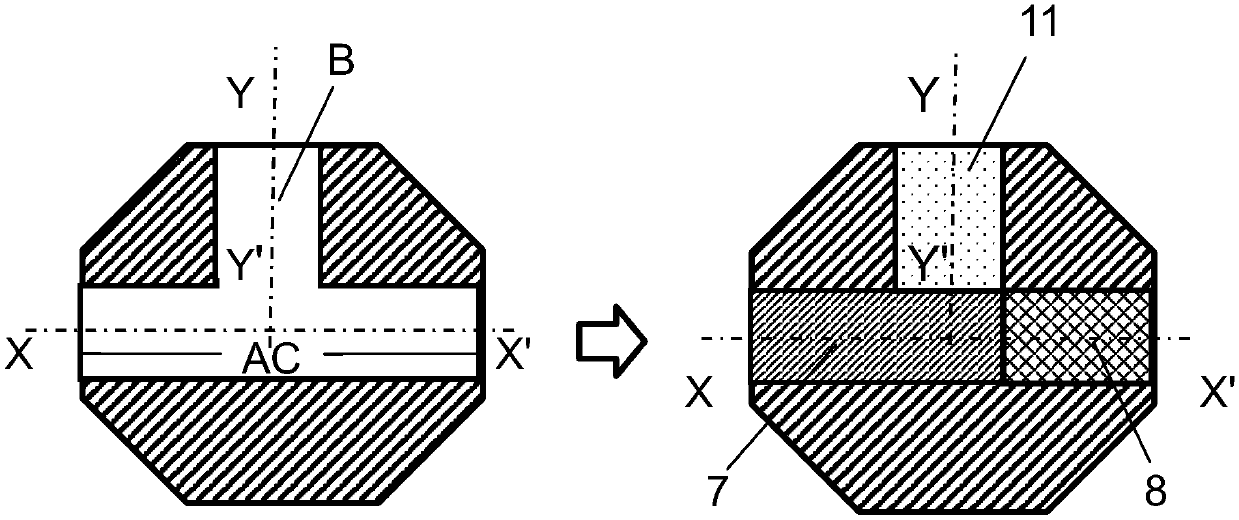

[0033] The octagonal corner extrusion die 3 is a regular octagonal concave die, and adopting a regular octagonal shape facilitates 90° turning and centering of the mold during corner extrusion.

[0034] The octagonal corner extrusion die 3 has inter-connected T-shaped die cavities for accommodating metal blanks 7 and forming extrusion channels, wherein the diameter of the vertical channel B is slightly larger, and the two horizontal channels AC are equal in diameter...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com